Why are engine speeds fluctuating?

The motor is the “heart” of the car, and like the human heart, interruptions sometimes occur in the work of this “organ”. We become aware of problems with the engine by the rhythm of its “heartbeats” - revolutions. If the speed of the power unit began to float, the motor gives us a signal that something is wrong with it. In our today's material, we will tell you what breakdowns jumping engine speeds hint at, how to properly diagnose and repair them.

The reason for the appearance of floating revolutions

The fact that the motor has something wrong with the speed, the driver can find out by looking at the tachometer. During normal operation of the power unit at idle, the arrow of this device is kept at the same level (usually within 750-800 rpm), and if the engine has problems, then the arrow either falls or rises (range from 500 to 1,500 rpm and higher). If the car does not have a tachometer, then floating speed can be heard by ear: the roar of the engine either increases or decreases. And also - along the growing and weakening, penetrating into the interior of the car from the engine compartment.

As a rule, unstable engine speeds appear at idle. But even at intermediate revolutions of the engine, dips or ups of the tachometer needle can be recorded - this is typical for. Let's consider these two cases separately to understand why these phenomena occur.

RPM fluctuations at idle

Floating idle speeds are most often seen on injection engines. This is due to the feature of regulating the operation of the idling system by the electronic engine control unit (ECU). The electronic "brains" of the car constantly read information about the idling operation, and if it is violated, they give the command to the sensors responsible for the correct functioning of the system to correct the situation. Idling may be disturbed due to the ingress of excess air into the fuel system, and specifically into the engine cylinders. In this case, the mass air flow sensor signals the ECU that excess air has entered the combustion chamber. To equalize the amount of air and fuel that together form the air-fuel mixture, the "brains" instruct the injector valves to open and let more fuel into the cylinders. At this point, the engine speed increases sharply. Then the ECU "understands" that it has supplied too much fuel to the cylinder, and limits its supply - at this moment, the speed drops sharply.

The second reason for floating idle speed is the failure of the idle speed controller ().

It is an electric motor, the design of which includes a conical needle, and its function is to stabilize the speed of the motor when it is idling. The main reason for its failure is the wear of the IAC elements (wire breakage, wear of the guides or the cone needle drive, etc.) due to long-term operation of the car on low-quality fuel. When the regulator breaks, the engine, left without a "stabilizer", begins to involuntarily increase or decrease speed.

The third reason for jumps in speed is a malfunction of the oil crankcase ventilation valve.

During the operation of the engine, exhaust gases accumulate in the crankcase (they are also called crankcase gases). If the engine is new, then the volume of such gases in the crankcase is relatively small, and for a motor with high mileage, the amount of crankcase gases is increased. Excess of these gases is removed through the ventilation system to the intake manifold and throttle valve, where they participate in the formation of the air-fuel mixture in the combustion chambers of the engine. If the crankcase ventilation valve jams (usually this happens due to the deposition of oil residues contained in the crankcase gases on its walls), a smaller amount of crankcase gases enters the intake manifold, TVZ is not fully enriched, engine speed starts to float - from medium ( 1100 - 1200) to low (750-800).

The fourth reason for the appearance of floating idle speed is the failure of the mass air flow sensor ().

It, like the crankcase ventilation valve, can become covered with a dirty oil film during long-term operation, which, in the end, leads to its breakdown. Quite rarely, a thermal anemometer breaks down in a DMRV - an element responsible for measuring the volume of air entering the engine combustion chamber. In this case, the ECU does not receive correct data on the mass air flow and requires it to be supplied to the cylinders, which responds to engine speed fluctuations.

The fifth reason is the incorrect operation of the throttle valve, the function of which is to regulate the pressure of the air supplied to the engine cylinders.

It can jam for two reasons: an oil coating appears on the inner surface of the “penny” of the damper, preventing the damper from closing and opening normally, and also due to a malfunction of the throttle actuator. Note that this is the most common reason for the engine to operate with floating speed at idle, which is also characteristic of carburetor engines.

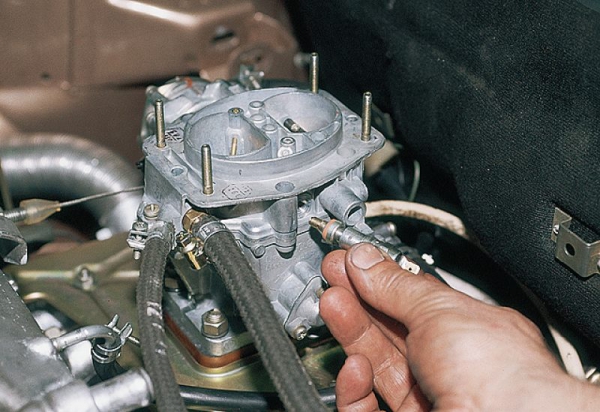

Speaking of carbureted engines, we list the reasons why they may experience jumps in idle speed. This is a) incorrect adjustment of the idle speed of the motor; b) breakdown of the carburetor solenoid valve; c) clogging of the idle jet with fuel combustion products.

Intermediate speed jumps

In diesel engines, intermediate speed floating is mainly due to the formation of rust on the blades in the high pressure fuel pump. Corrosion of these pump parts occurs due to the presence of water in the fuel. By the way, for the same reason, the speed of the diesel engine also jumps at idle.

All of the above reasons for the appearance of unstable engine speeds have several consequences: fuel, exhaust gases with a high CO content, wear of the elements of the fuel system and the engine air supply system. To prevent this, it is necessary to periodically check the operation of the systems and sensors listed above, and if the trouble still happened, and the speed is “feverish”, immediately repair all the breakdowns.

Correcting floating engine speed

1. Air leak into the engine cylinders. It is necessary to check the tightness of the lines of the air supply system to the intake manifold. To do this, you can remove each hose individually and blow it through with a compressor or pump (a laborious process), or you can treat the hoses with WD-40. In the place where the "vedeshka" quickly evaporates, it will be possible to detect a crack. In this case, we recommend not to seal it with electrical tape, but to replace the worn hose with a new one.

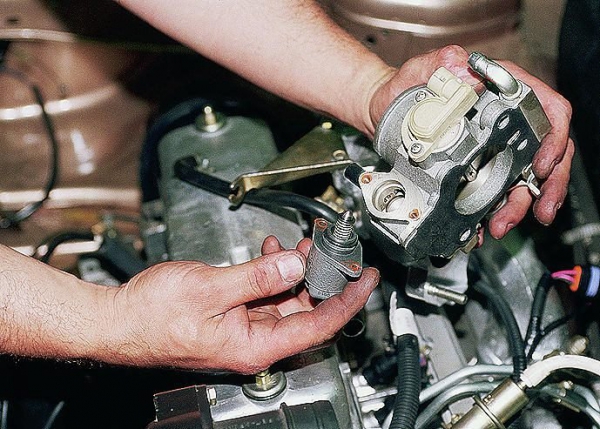

2. Replacement of the regulator of idling. The state of the IAC is checked with a multimeter, which we measure its resistance. If the multimeter shows a resistance in the range from 40 to 80 ohms, then the regulator is out of order and will have to be replaced.

3. Cleaning the crankcase ventilation valve. Here you can not do without disassembling the oil sump - this is the only way to get to its ventilation and remove the valve. We wash it in kerosene or any means for cleaning engine parts from traces of oil sludge. Then dry the valve and install it in place.

4. Mass Air Flow Sensor Replacement. DMRV is a delicate part and in most cases cannot be repaired. So if it was he who became the cause of the floating idle speed, it is better to replace it rather than repair it. Moreover, it is impossible to fix a failed hot-wire anemometer.

5. Flushing the throttle valve with the subsequent installation of its correct position. There are two ways to clean the throttle valve from oil deposits - by removing the valve and flushing it without removing it from the car. In the first case, disconnect all hoses and wires leading to the damper, loosen its fasteners and remove it. Then put in a container and fill with a special aerosol (for example, Liqui Moly Pro-line Drosselklappen-Reiniger).

If the oil sludge on its surface is old, it can be gently cleaned with a brush. Then blot the damper surfaces with a clean, dry rag and install it in place, connecting all hoses and wires. In the second case, the throttle valve is flushed on a hot engine with the same aerosol. The damper must be de-energized before applying the cleaning agent. First, pour the aerosol into the damper, wait a couple of minutes and start the engine. With the engine running, continue spraying the damper. If at the same time white smoke pours from it - it's not scary, it removes oil sludge. At the end of the procedure, we connect the wires, and using a computer, we reprogram the algorithm for its operation, setting the desired damper opening gap.

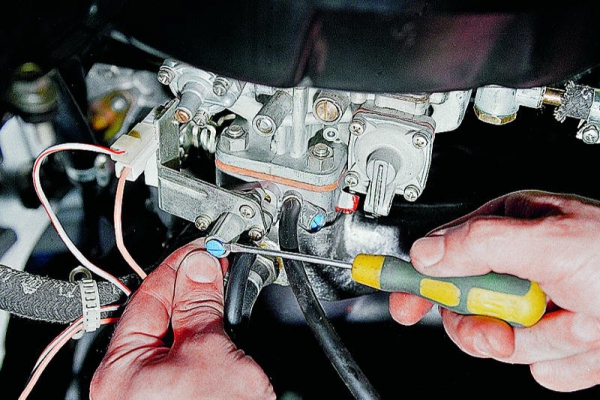

6.. This operation can be carried out with a screwdriver, adjusting the screws for the number and quality of revolutions.

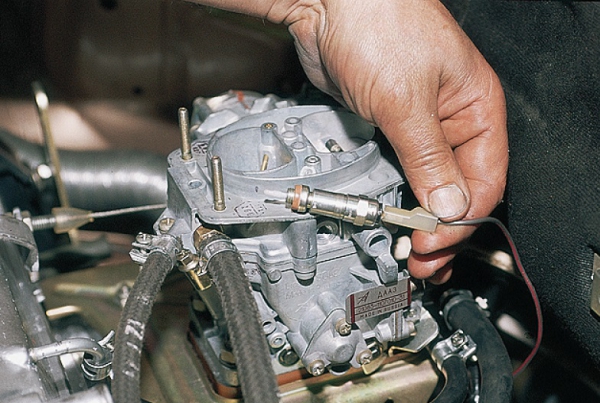

7.Carburetor Solenoid Replacement. If this valve breaks down, the engine can only run on air suction. Therefore, to eliminate speed surges, we recommend replacing the solenoid valve with a new one.

8. Cleaning the idle jet. About twenty years ago, cleaning the jet from oil deposits was a laborious operation. Today, you do not need to remove the jet from the system - just pour a special aerosol for cleaning carburetors into it and leave the product there for five minutes. After this time, the jet should be cleaned of dirt residues with compressed air.

9. Treatment of high pressure fuel pump blades against corrosion. To do this, you need an anti-corrosion agent (for example, XADO VeryLube), which can be simply sprayed into the fuel tank before refueling. Cleaning the pump blades from corrosion, this tool will perform independently. To prevent corrosion of the pump blades, you can pour 200 ml of engine oil into the tank, which, during the ride, will create a protective film on the surfaces of the blades.

Remember: when there are jumps in engine speed at idle, you must contact the service station and conduct a detailed check of the operation of these engine systems. Timely diagnosis will save you from serious damage to the motor components.