Symptoms of a malfunctioning inner joint

In the 80s of the last century, an important stage in the mass production of passenger cars began: the transition from the classic design with a cardan shaft and rear axle to front-wheel drive. Front-wheel drive with MacPherson suspension has proven to be a simple and reliable system with a number of advantages:

- increased handling and cross-country ability due to the weighting of the front of the car;

- stable directional stability of the machine, especially on slippery surfaces;

- increase in the usable area of the cabin due to the compact dimensions of the engine compartment and the absence of a cardan shaft;

- reduction in vehicle weight due to the absence of a gearbox and rear-wheel drive elements;

- increasing the safety of the structure and increasing the dimensions of the luggage compartment by installing a fuel tank under the rear seat.

However, to transfer rotation to the drive wheels, a number of vulnerable parts and assemblies were introduced into the design. chief, heavily loaded transmission element in front-wheel drive cars are constant velocity joints (CV joints).

Operating principle

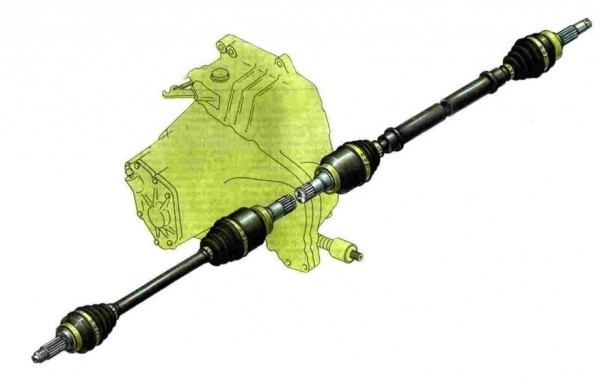

The gases produced during the combustion of fuel expand and press on the pistons that drive the crankshaft of the engine. Through the flywheel and clutch, rotation is transmitted to the gears of the gearbox. For the movement of the driving wheels, the design includes two semi-axes, with hinges of equal angular velocities fixed at the ends. The inner CV joints are inserted into the gearbox, and the outer joints are attached to the front wheel hubs.

Due to the use of CV joints, the torque is stable regardless of the angle at which the wheels are turned. This scheme allows the car to move when cornering and maneuvering.

CV joint design

The CV joint is a bowl-shaped body with a semi-axle (trunnion), into which a cage and a separator with bearings are inserted. Special grooves are applied on the outer surface of the holder and the inner side of the body. In motion, the inner race transfers force to the CV joint housing, causing it to rotate. When the angle between the axle shafts is changed (the steering wheel is turned), the bearings move in the grooves, and the transmission of torque to the drive wheels does not stop.

The dimensions of the parts are different: the inner CV joints are made more massive than the outer ones.

There are two types of hinges: conventional (with ball bearings that move along the pitch grooves) and tripoid, in which three rollers with hemispherical surfaces rotate on needle bearings. According to their design, the hinges can be collapsible and non-collapsible.

For the manufacture of CV joints, high-strength alloys are used, which theoretically guarantee a long service life of the assembly and the absence of malfunctions.

Symptoms

First of all, external CV joints fail due to the greatest load on the structure in the wheel hubs and the maximum rotation angles of the outer part of the drive. Internal hinges are more durable, however, over time, wear is formed on the contacting parts of the CV joints, which further leads to a malfunction of the part. As a result, the bearings have free play in the enlarged cavities, and the hinge begins to emit a sharp metallic crack.

Advice! To understand the symptoms of a malfunction, you can compare the crunch of a failed CV joint with a sharp sound that a manual transmission makes when trying to turn on reverse gear when the car is still rolling forward.

For external CV joints, this symptom appears when driving with the wheels turned to the extreme positions. In the presence of a malfunction, the internal hinges crackle when coasting in a straight line, when starting off, and also when driving under load (for example, on a hill).

The crackling of the internal hinges is especially pronounced with large suspension travels (straight driving over bumps or off-road).

Also, in the event of a CV joint malfunction, jerks when turning the drive wheels, clearly visible to an observer from the side when driving slowly on a flat area.

To confirm the malfunction, you can check for backlash at the inner CV joint: if the drive has free play, an urgent replacement is required.

The rapid failure of internal and external CV joints is due to one of the following reasons (or a combination of them):

- particles of dirt, dust or water entering the hinge mechanism through damage to protective covers (anthers),

- insufficient amount of lubrication in the CV joint mechanism;

- poor workmanship of parts or metal defect;

- tough driving style on broken roads (starts with slippage, sharp steering turns to extreme positions at high speed, etc.).

Methods of self-diagnosis

To reliably assess the condition of internal CV joints, the following method is used:

On a flat surface, the car is put on the parking brake, the rear wheels are blocked by wheel chocks or auxiliary items.

With the help of a jack and two props, the front of the machine is hung out so that the drive wheels do not touch the ground.

The engine starts, the first gear is engaged (for automatic transmission - mode D). If a sharp metallic crack or crunch is periodically heard during the slow rotation of the front wheels, then the internal CV joints are faulty. It is in this way that the condition of the internal hinges is determined at service stations by lifting the car on a lift.

You can get a detailed idea of \u200b\u200bthis diagnostic method from the following video:

Additionally, it is worth inspecting the anthers for damage and leakage of lubricant, as well as check the play of the structure. To do this, shake the drive in different directions, preventing the axle shaft from turning.

Warning! A faulty internal CV joint can fall apart or pop out of the transmission at high speed and cause a serious accident. It is necessary to carry out diagnostics and eliminate the identified defects of drives in a timely manner.

The classic version of the troubleshooting of internal CV joints, which is given in many operation and repair manuals, is highly laborious:

As a rule, to replace the part, it is necessary to remove the front wheel, unscrew the fasteners of the suspension elements and remove the corresponding drive shaft assembly with equal angular velocity joints. Also, this operation requires that the transmission oil be first drained from the gearbox by at least 1/3 of its total volume.

![]()

In some cases, it is necessary to knock the hinges off the shaft with a hammer, and sometimes to remove parts of the collapsed CV joint from the axle shaft, you need to use a cutter or grinder.

For owners of vehicles with SHRUS collapsible design, there is an alternative, faster option: It is necessary to open the clamps and move the anther of the inner CV joint onto the axle shaft. Then the bolts on the inner hinge are screwed together, as a result of which the structure is held by the fit of the flange. By turning the front wheels to the extreme positions, you can achieve a situation in which the drive will fall out of the gearbox on its own. After that, it remains only to replace the inner CV joint, add lubricant, install a new boot and assemble the structure.

Knowing the typical symptoms of failure of internal CV joints and understanding the potential causes of this malfunction will allow you to detect a breakdown in time and take measures to ensure the safe operation of the car.