Longitudinal play of the steering column gazelle business. Features of the design of the steering of the car gazelle

Page 1 of 2

Adjustment of the steering gear GAZ-2705

Steering column adjustment must be done after adjusting the driver's seat in relation to the control pedals. For this you need:

Turn the handle 23 towards you and up, loosening the fixation of the steering column;

- set the steering wheel in a comfortable position;

- fix the selected position of the steering column by turning the handle 23 down and away from you.

Bearing adjustment carry out when an axial or radial clearance appears in the propeller bearings 2 (Fig. 2) To make sure that these clearances are present, it is necessary:

Turn steering wheel 2.5 turns from position rectilinear motion in any direction;

- shake the screw of the steering mechanism for the fixed fork by hand; if at the same time the screw will have axial or radial movement (play of the fork relative to the steering gear cover), then the screw bearings must be adjusted.

Adjustment is made in the following sequence:

. disconnect the bipod 18 and the fork shaft 12 of the steering wheel;

. unscrew the bolts securing the steering mechanism to the bracket and remove the steering mechanism from the vehicle;

Drain the oil through the hole closed with plug 4;

. remove two plugs 20 on the crankcase;

. remove two covers 17 and 19 and sponge seal 16 of the sector shaft;

. remove the retaining ring 14;

. straighten the holes on the bearings of the sector shaft with a beard and remove them with a puller, eliminating shocks and distortions on the bearing;

. remove shaft-sector 3;

. unscrew the bolts securing the upper crankcase cover, remove the cover and remove one of the shims 5;

. install the crankcase cover in place and check the torque of the screw in the bearings. The moment should be 0.4-0.8 Nm. In this case, no play of the screw should be felt;

Install the sector shaft 3 and bearings, lubricating the seating surfaces and sealing rings with steering gear oil. During installation, the bearings must be directed eccentrically downwards (the shaft-sector is as far as possible from the ball nut). Distortions during assembly are not allowed. Jamming of bearings on the shaft-sector or crankcase indicates a misalignment or incorrect orientation of the bearing eccentricities;

. adjust the engagement in the nut-sector pair;

. to fix the bearings of the shaft-sector from rotation by bending the shoulder on the bearings into the holes on the crankcase;

. assemble the steering gear in reverse order;

. install the steering gear on the car;

. pour oil;

. install bipod 18 and shaft yoke 12 (when installing wedge 10, nut 6 and washers should be on the side of the machined end on yoke 8).

Adjusting the engagement of a pair of nut - sector of the steering mechanism.

The gap in the engagement of the working pair is considered acceptable if the play at the lower end of the bipod with the wheels positioned for moving in a straight line with the propeller bearings adjusted is not more than 0.3 mm. If the backlash exceeds this value, then it is necessary to adjust the engagement of the nut-sector pair, since the operation of the car with excessive backlash leads to failure of the steering mechanism.

The sequence of operations for checking the engagement of a pair is as follows:

- put the wheels in the position of driving in a straight line and turn the steering wheel to combine the risk " WITH» at the end face of the screw with a rib « IN» top cover 9 (notch « ABOUT"should be at the bottom);

- disconnect the longitudinal steering rod from the bipod;

- shaking the bipod with your hand, determine the play at its end (in this case, the axial play of the screw should not be felt). If the bipod play is more than 0.3 mm, adjust the engagement of the pair in the following order:

. remove the steering gear from the car;

. remove two plugs 20 on the crankcase near the sector shaft;

. disconnect the bipod 18, remove the two covers 17 and 19 and the sponge seal 16 of the sector shaft;

. straighten the holes on the bearings of the shaft-sector 3 with a beard;

. adjust the engagement of the nut with the sector by simultaneously turning the outer rings 15 in the crankcase holes clockwise from the side of the splines on the sector shaft. When adjusting, exclude the possibility of misalignment of the shaft-sector in the outer rings (wrong orientation of the bearing eccentricities).

The torque of the screw on the adjusted mechanism should be 1-1.8 N:

- fix the bearings of the shaft-sector from rotation by bending the shoulder on the bearings into the holes on the crankcase;

- re-check the moment of rotation of the screw and the play at the end of the steering arm;

- install two plugs 20 on the crankcase, sponge seal 16 of the shaft-sector (having lubricated it and the shaft-sector under it with grease), two covers 17 and 19 and bipod 18;

- install the steering mechanism on the car;

- connect the tie rod to the bipod and cotter pin.

On the new steering gears, the screw turning torque has been increased (to compensate for the running-in of parts) up to 1.8 ± 0.35 Nm.

If you need to adjust the column fixation mechanism, you must:

Remove the lower casing 8 by unscrewing two screws and releasing it from the lower retainer;

- remove the upper casing 24, bringing the dispenser as close as possible to the driver;

- after loosening the locknut, tighten the bolt to a torque of 9.0-12.5 Nm (0.9-1.25 kgf/m);

- fix the locknut with a torque of 14-18 Nm (1.4-1.8 kg / m), eliminating the bolt loosening;

- check column fixation;

Install the top and bottom covers.

Page 1 of 2

Features of the steering of the car Gazelle

On a Gazelle car can be installed steering both without power steering and with power steering.

Steering without hydraulic booster

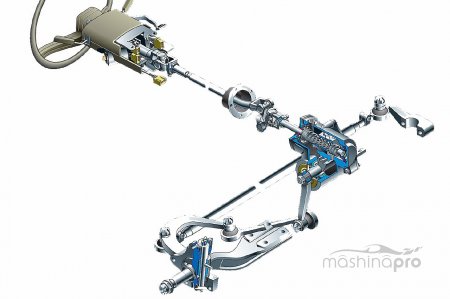

The vehicle is equipped with a steering system consisting of a steering column with a wheel, a steering mechanism and a steering drive. The steering column allows you to change the position of the steering wheel in height and angle. The upper end of the steering column shaft is connected to the steering wheel by conical splines, and the lower end is connected to the steering gear screw through cardan joints.

The steering mechanism consists of an aluminum crankcase, a screw with a ball nut and a sector shaft.

rice. 1 |

The screw is mounted in the crankcase on two angular contact ball bearings. A ball nut is installed on the screw, which has a helical groove inside. A set of balls is placed between the nut and the screw. As the screw rotates, the balls roll along the helical groove and the ball nut moves along the screw. At the same time, with its teeth, the nut turns the shaft-sector installed in the crankcase on two roller bearings. A steering arm is fixed on the conical splines of the sector shaft. The ball screw and ball set are matched to each other and, if necessary, can only be replaced as a complete unit. The ball nut engagement with the sector shaft is adjusted by turning the eccentric cages of the sector shaft bearings. The steering mechanism is lubricated with gear oil (0.5 l) filled into the crankcase through a plug with a conical thread. The steering drive consists of a bipod, longitudinal and transverse steering rods, wheel steering knuckle levers and steering rod joints. The steering arm is connected by a longitudinal link to the steering knuckle arm of the left front wheel. The tie rod connects the levers of both wheels, synchronizing their rotation. Its length can be adjusted, which allows you to change the angle of convergence of the wheels. The angle of the longitudinal and transverse inclination of the axis of rotation and the camber of the front wheels are set by the design of the front suspension and are not regulated during operation. All hinges connecting the elements of the steering gear are unified, non-separable and do not require maintenance in operation.

Steering with hydraulic booster combined with steering gear

In the steering mechanism with a built-in hydraulic booster, instead of a roller, a three-tooth sector is cut on the bipod shaft, and the role of the worm is performed by a screw connected to a piston-rack mounted on two thrust bearings, the preload of which is regulated by a nut. In the crankcase of the steering mechanism, a hydraulic booster cylinder is made, in which a piston-rack moves along the screw. The piston is made integral with the ball nut and has teeth engaged with the teeth of the bipod shaft sector. The piston divides the cylinder into two cavities. When the steering wheel is stationary, the pressure in them is the same. Depending on the direction of rotation of the steering wheel, the corresponding cavity of the cylinder is connected through a hydraulic distributor to the high-pressure supply line, and the other to the outlet. The fluid (oil) pressure in the power steering hydraulic system is created by a vane-type pump with a belt drive from the crankshaft pulley mounted on the front of the engine. IN expansion tank power steering hydraulic system has a filter element that traps particles larger than 45 microns. The steering drive consists of steering trapezoid rods, bipod rods and levers. Self-compressing collapsible hinges with hemispherical fingers are pressed into the eye of the pendulum lever and into the ends of the rods. The tie rods of the steering trapezoid have adjusting tubes, and corrugated rubber seals with a metal clip are pressed on the shoulders of their tips. The hinges of the bipod and pendulum lever are protected by cap rubber seals.

A few years ago, Gazelle cars were recognized as the best people's commercial vehicle in Russia. And this is true - it is difficult to imagine today's roads without busily scurrying minibuses or trucks of a well-known domestic brand. Professional drivers value them for their reliability and ease of use.

Commercial vehicles involve intensive use, so here the units often work at the limit, which leads to their breakdown. Special loads fall on the governing bodies, including steering column of a Gazelle car. Most experienced drivers cope with repairs on their own, using the accumulated experience of colleagues in the shop.

Control system device

Engineers of the GAZ automobile plant have developed a system based on the “screw-ball nut” design and consisting of:

- steering wheel;

- cardan shaft and hinge;

- bipod shaft with a toothed sector;

- column pipes;

- bearings;

- glands.

The column shaft rotates on two bearings, which do not need to be adjusted during operation. The control wheel is placed on the conical splines of the shaft and secured with a lock washer and nut.

Maintenance of the main nodes

The condition of the nodes of one of the most important systems most directly affects traffic safety. Those who give this issue due attention, they can foresee troubles along the way and avoid the irreparable. Inspection and control of the main parameters will not take much time, but it will save life.

What to check first:

- fixing the main nodes;

- free wheeling "steering wheel";

- axial play in bearings;

- gear gap.

In addition, lubrication of the units should be carried out in accordance with the vehicle lubrication map. If the free play of the control wheel exceeds 25 ° for GAZ-2705 and GAZ-2705 (for buses 20 °), then the tightening of the bearings and gear mechanism must be adjusted. On machines with hydraulic booster, be sure to check the level of the working fluid in a special reservoir.

Adjusting the steering column Gazelle before operation

The design of the node is such that it allows you to adjust the position of the "steering wheel" in terms of inclination and height. To carry out this operation, there is a latch that should be moved to the upper position, set the control wheel in a convenient position and return the latch to its place.

The design of the node is such that it allows you to adjust the position of the "steering wheel" in terms of inclination and height. To carry out this operation, there is a latch that should be moved to the upper position, set the control wheel in a convenient position and return the latch to its place.

If the stopper has ceased to fulfill its purpose, then it is necessary to unscrew the lock nut with two keys to “13” and tighten the handle fasteners. Then tighten the locknut and put the casing in place.

Typical malfunctions of vehicle control units

The malfunctions of these units, first of all, have external signs, which are expressed in:

- extraneous knocks;

- increase in backlash;

- tight management;

- vibrations;

- fluid leakage;

- noise during hydraulic operation.

The causes of the above problems may be violations of the rules of operation and unqualified maintenance. The most common defect is the backlash of the Gazelle steering column, to eliminate which it is necessary to replace the shaft bearing bushings. To do this, the assembly must be dismantled, as described below.

Removal and disassembly procedure

First, disconnect the battery and set the front wheels to the “straight” position. Further work goes on the points:

- Remove the trim and unscrew the steering wheel nut with a wheelbrace to "24".

- Dismantle the RC from the splines of the shaft with a special puller.

- Remove the lower part of the casing by unscrewing the two screws.

- Put the column in the upper position and remove the upper part of the casing.

- In the engine compartment, remove the cotter pin of the wedge and unscrew the nut to "13".

- Knock out the wedge with a brass mandrel and remove the yoke.

- Remove the spring clips of the seal.

- Unscrew the 4 column mounting bolts and remove with the cardan shaft.

- Remove the cross fork from the shaft and disconnect.

- Dismantle the bracket - unscrew the bolt and pull out the bushing.

Assembly and installation takes place in the reverse order. Before you put the "steering wheel", you should make sure that the wheels are in a straight position. For those who perform similar works It will not be superfluous to recall the observance of safety regulations.

Page 1 of 2

Adjustment of the steering gear is needed when the car's directional stability is low at high speed (you don't feel the steering wheel at high speed).

This defect is associated with a violation of the regulation thrust bearings screws, and in a pair of rack-piston - shaft-sector of the steering mechanism.

After adjustment, the force required to rotate the input shaft should not increase noticeably. During operation, you should constantly monitor the condition of the hoses, especially high pressure. In case of cracks, swellings and cuts, the hoses must be replaced. You should also check for leaks of the working fluid (oil) from under the hose clamps, steering gear covers or power pump. With an increase in pressure in the system due to jamming of the bypass valve, it can squeeze out the technological plugs in the pump housing, so you should monitor the system and the quality of the working fluid being filled in, top it up, replace and change the filter in time. Do not hold the steering wheel in extreme positions for a long time. This can damage or even seize the booster pump. Weak noise during the operation of the amplifier is not a sign of a malfunction.

Adjustment

|

We remove the steering mechanism without removing the bipod. |

|

|

|

3. |

|

At the same time, we control the moment of rotation of the shaft, which should be no more than 0.2 kgcm. |

5. |

Commercial vehicles do not need to have a lot of equipment on board that contributes to comfortable and safe driving. Although it was possible even for a deep scoop. Recall at least the RAF 2203, which was considered almost a model of comfort for a minibus. Despite the fact that it was assembled completely on the nodes and assemblies of the Volga. It's time to erect a monument to this icon of Soviet minibuses and ambulances - the RAF not only somehow did not deteriorate from congenital Volga diseases, it managed to become an absolutely self-sufficient and comfortable vehicle.

What happened, then passed, and GAZ 3302 GAZelle came to replace Rafik, on which they had high hopes. As a result, for 20 years of production, it has remained a gasoline tractor with a steering wheel and a gearbox poker, having managed to pick up incurable diseases with the most primitive design. Since there is no choice in this price segment at all, the car enjoys forced popularity and strained love of drivers.

Features of the steering gear GAZ 3302

Like the whole car, the GAZelle does not suffer from the sophistication of the design, but many believe that this is for the better. Regardless of whether the car is with power steering or without power steering, repair and steering adjustment are extremely simple and do not require deep encyclopedic knowledge and special tools from the driver. The very minimum of both - and you can go further.

Video review of GAZelle 3302

It is still different from the prehistoric GAZ worm-roller gearboxes, and even has its positive aspects. The most pleasant feature from the point of view of car architecture is that the GAZelle gearbox mechanism is quite compact and at the same time has good efficiency. What is especially noticeable on cars without power steering - driving even a loaded car does not require the use of brute physical force. The designers achieved this by using rolling instead of sliding. It cannot be said that this introduction brought revolutionary changes to the global auto industry at the end of the 20th century, but the steering wheel became noticeably lighter. This made it possible to increase the resource of the entire assembly, since it does not wear out as intensively as a worm pair, and rarely requires adjustment.

Not without flaws, although the designers have nothing to do with it. A working pair of screw / ball nut is a non-dismantling element, and for the first 10-15 years of car production, it was quite difficult to find a replacement pair. Now this stuff is enough, so replacing a working pair can cost 5-6 thousand rubles. Adjusting the steering gear involves its complete dismantling, which also does not cause delight among users. Moreover, to adjust the gap, in addition to the key of a special profile, even and skillful hands are also required, since the bearings can be skewed in a jiffy if you do not use a torque wrench.

But the main surprise for the driver who decides to adjust or repair the gearbox is the dismantling of the bipod. This is not hellish work, but in the cold, dismantling the bipod can cause some discomfort.

GAZelle steering gear repair

From a good life, no one wants to remove the steering gear with their own hands, and the reasons for this must be more than good. Basically, this is necessary if the steering wheel is noticeably heavier, characteristic knocks appear in the gearbox housing, or there is a clear lubricant leak. The gearbox always sweats, but if the leak is too active, then the replacement of the seals shines. In this case, it is necessary to check the condition of the shaft and, if necessary, remove traces of corrosion by grinding.

You can make adjustments without completely dismantling the gearbox, but it will be calmer if you still remove it and inspect it carefully.

For the curious or for those in a hurry, we present the technology for dismantling the gearbox from under the hood:

- Loosen the front wheel mount.

- We post front axle stand and remove the wheels.

- We turn the steering wheel all the way to the right and from under the hood we knock out the steering rod with fittings that are suitable in length.

- We do the same on the left.

- From under the hood we remove the gearbox along with the bipod, which is more convenient to remove on a workbench.

When the gearbox is in our hands, we can repair it. Replacing parts should not present any difficulties, since the gearbox is extremely simple and understandable, and you need to pay some attention to the adjustment and refer to the factory adjustment data. They are also extremely simple.

For cargo GAZelles, the allowable backlash is 25˚, for passenger ones - 20˚. According to factory tolerances, there can be no play in the bearings of the gearbox. The clearance in the screw bearings is adjusted in a vise on a workbench. It is more comfortable. We remove the plastic protection and the foam seal, then unscrew the four bolts securing the cover, take out one of the shims, and then assemble everything in the reverse order. If there is play, repeat the operation to dismantle the gasket. So until full satisfaction and elimination of backlash on the bipod.

When the play on the bipod is fully selected, we get to the adjusting eccentric rings. You need to turn them one by one to avoid skew and with a certain effort - 10-18 kgf / cm. Adjustment is complete, now you can moisten the foam seal in gear oil, splined connections with grease and install the steering gearbox in place.

- News

- Workshop

Ravon R2 will reach Russia, despite the arrests of the brand's management

Recall that earlier the Uzbek media reported that the Russians did not receive prepaid Ravon R2 hatchbacks due to the arrest of the head of GM Uzbekistan Tokhirjon Jalilov: they say cars intended for sale in Russia were involved in a large-scale scam. But, as the press service of the brand notes today, “General Motors Uzbekistan JSC has begun shipping the Ravon model ...

Daniil Kvyat leaves Red Bull Racing

Daniil Kvyat himself will continue his career in the Toro Rosso team. About this with reference to a source familiar with the situation, the agency "R-Sport". Thus, already at the Formula 1 Grand Prix in Spain, which will be held in Barcelona on May 13-15, Kvyat will drive the Toro Rosso. As the head of Red Bull Racing Christian Horner explained, the team is happy to give ...

The authorities figured out how to reduce the accident rate on the Moscow Ring Road

As calculated in the capital's Department of Transport and Road Infrastructure Development, the installation additional lighting will reduce the number of accidents by 20%. This was reported by the press service of the department. As Maxim Liksutov, head of the Moscow Deptrans, explained, Moscow Mayor Sergei Sobyanin instructed to take measures to improve security on the Moscow Ring Road. It is known that improved lighting ...

The authorities refused to believe in the growth of the Russian car market

According to the agency's baseline scenario, 1.4 million vehicles will be sold in Russia in all of 2016, or 6.7% less than in 2015. This was reported by Interfax with reference to the Deputy Minister of Industry and Trade Alexander Morozov. In addition to the baseline scenario, the Ministry of Industry and Trade presented several more forecasts for the development of the situation on the Russian car market. ...

In Russia, the cost of OSAGO repairs has risen

As stated in the official statement of the Russian Union of Motor Insurers (RSA), compared with December 2015, the average cost of spare parts in the new directory increased by 4-5%. This indicator was calculated after analyzing the updated costs of the most damaged parts. In total, 7 thousand positions were checked. It is noteworthy that insurers are talking about a rise in price ...

Transfers in public transport can become free

The Moscow Department of Transport is considering the possibility of making free transfers on ground public transport, said Deputy Mayor of the capital Maxim Liksutov, quoted by Interfax. A specially conducted study showed that most passengers are ready to travel with transfers, but only if they do not have to pay the fare twice, and the transfer itself takes ...

Russia and China will be connected by a new autobahn

It is planned to allocate 783 billion rubles for the construction of the Moscow-Sagarchin (Kazakhstan) section, 50% of which should be budgetary funds. The first deputy chairman of the board of Avtodor for investment and financial policy, Innokenty Alafinov, spoke about this, RIA Novosti reports. At present, part of the road is already under construction, and the announcement of tender procedures on the site...

Thousands of kilometers of highways will appear in Russia

The approval of the program by the Russian government is scheduled for 2017. This was announced to Izvestiya by Alexander Nosov, Deputy Chairman of the Board for Investment Policy and Corporate Development of Avtodor. Currently, the first stage is being implemented, which provides for the creation of high-speed road links between the Central, Southern and North-Western regions. Roads are currently under construction...

Compiled a portrait of a typical car on Russian market

The corresponding study was carried out by the specialists of the project "The Right Price" and the company "Avtostat Info". Based on data on 104,000 three-year-old cars sold, a portrait of "typical" cars in the mass and premium segments was compiled. As it turned out, the most popular modification of a mass-produced three-year-old car with mileage was a front-wheel drive sedan with a gasoline engine with a power of ...

Citroen C4 updated and cheaper

The cost of the most affordable version of the sedan will be 899 thousand rubles. Interestingly, after the update, C4 even fell in price: pre-reform cars, excluding discounts and promotions, are now being sold by Russian dealers for 969 thousand. In the basic version, Citroen is equipped with a 115-horsepower 1.6-liter engine and a 5-speed manual. In addition, there will...

CHOOSE a car: "European" or "Japanese", Purchase and sale.

CHOOSE a car: "European" or "Japanese", Purchase and sale.

Choosing a car: "European" or "Japanese" new car, the motorist will undoubtedly face the question of what to prefer: the left hand drive of the "Japanese" or the right - legal - "European". Unstable engine operation: injector valves jump on Idling Causes of sensor fire ...

The most expensive cars in the worldThe most expensive cars in the world

Of course, any person at least once wondered what is the most expensive car in the world. And even without receiving an answer, he could only imagine what the most expensive car in the world is like. Perhaps some think that it is powerful, ...

HOW to choose your first car, choose your first car.HOW to choose your first car, choose your first car.

How to choose your first car Buying a car is a big deal for the future owner. But usually the purchase is preceded by at least a couple of months of choosing a car. Now the car market is filled with many brands, in which it is quite difficult for an ordinary consumer to navigate. Unstable engine operation: jumping ...

1. We clamp the mechanism in a vice with the fittings down and drain the remaining oil into the container, turning the shaft of the mechanism with a key by 17.

1. We clamp the mechanism in a vice with the fittings down and drain the remaining oil into the container, turning the shaft of the mechanism with a key by 17. 2. Pressing the spool shaft with your hand, we swing the bipod. If at the same time axial play of the shaft is felt, adjust the thrust bearings.

2. Pressing the spool shaft with your hand, we swing the bipod. If at the same time axial play of the shaft is felt, adjust the thrust bearings. To do this, straighten the collar of the adjusting nut through the beard or drift, which is centered in the grooves of the crankcase.

To do this, straighten the collar of the adjusting nut through the beard or drift, which is centered in the grooves of the crankcase. 4. With a special key, turn the nut clockwise until the gap is eliminated.

4. With a special key, turn the nut clockwise until the gap is eliminated. To do this, with a dynamometer hooked to the key at 17, we measure the moment of turning the spool shaft.

To do this, with a dynamometer hooked to the key at 17, we measure the moment of turning the spool shaft.