What sensors affect idling. How to clean the idle speed sensor and when to do it

Every car, without exception, needs timely maintenance. This is quite normal, because different nodes have certain operational properties. And the breakdown of any device gives the driver a lot of inconvenience.

However, don't give up right away. Every fault can be fixed if the right approach is applied. Thus, it will be easy enough to explain the causes of each breakdown.

One of these troubles that prevents the driver from driving the VAZ-2110 normally is a sensor breakdown. idle move(DHX or RXX).

A bit of theory

A sensor is an element that belongs to the category of measuring instruments. Basically, such a node is used to analyze, process and convert incoming information with subsequent output to a display board.

Among car owners, the idle speed sensor is referred to as the abbreviation IAC. This is one of the most important details in the internal combustion engine, which is responsible for the stable operation of the vehicle.

This regulator is an executive device, and it is not easy to identify malfunctions in its operation. All this is due to the fact that there is no self-diagnosis in VAZ cars. For example, if the IAC fails, the “check engine” error will not appear.

How RHX works

The functional unit regulates the amount of air supplied to the motor when the throttle is in the closed state. This is necessary to provide automated regulation of engine speed at idle.

The sensor is also involved in the process of warming up the internal combustion engine to operating temperature in cold weather. IAC operating range from -40 to +130 degrees.

When the ignition is turned on in the car, the stem on the regulator extends to the stop and rests against the calibration place of the throttle pipe. The IAC counts the steps and the valve returns back.

With the motor turned on, with an increase / decrease in steps, the amount of passing air masses changes. The right amount of air mass is supplied to the motor, which will ensure normal operation at idle.

IAC on the VAZ-2110 is small in size and consists of three nodes:

- Stepper motor.

- Springs and stem.

- Conical needle.

The device is fixed on the body of the throttle assembly with two threaded screws.

What could be a malfunction of the sensor

Breakdowns in the functioning of the regulator cause a large number of problems to the car owner. Accordingly, ignoring the problem for a long time can provoke an accident. Therefore, do not neglect your own safety and it is advisable to identify the malfunction in the early stages.

Breakdowns in the functioning of the regulator cause a large number of problems to the car owner. Accordingly, ignoring the problem for a long time can provoke an accident. Therefore, do not neglect your own safety and it is advisable to identify the malfunction in the early stages.

Signals of a faulty regulator:

- The engine rpm fluctuates constantly. You may notice a sudden increase / decrease in this indicator.

- When starting the engine cold, there is no increase in speed.

- When you turn on additional electrical appliances (headlights, stove, etc.), the speed at the idle decreases noticeably.

- The internal combustion engine stops at idle and when the gear is engaged.

In practice, there are other signs of IAC malfunctions, but in order not to be mistaken and not to confuse a sensor malfunction with other breakdowns, it is important to know how the node in question is checked.

Checking the health of the IAC

Initially, put the car on the handbrake and put wheel chocks under the wheels. Next, get access to the device, disconnect it from the block of power wires. The next step is to check the voltage with a regular voltmeter. Checked contacts: minus the internal combustion engine and plus on the contacts of the wire block A, D.

For a correct check, turn on the ignition and evaluate the information you received. The voltage on the device should be no more than 12 volts. If the indicator is less, then there may be problems with the battery. If there is no voltage at all, then you need to check the electronic control unit and the entire circuit completely.

Next, inspect with the ignition on. Check conclusions A:B, C:D. The optimal resistance should be about 53 ohms. With the sensor dismantled and the ignition on, if a power supply is connected to it, then the conical needle should move. If nothing like this happened, the node is faulty.

Otherwise, the malfunction lies in the operation of the regulator, but do not panic and immediately go to the service station. You can replace the node in question or clean it yourself.

Cleaning or replacing the IAC with a VAZ-2110

Regulator maintenance is a fairly simple matter that does not require much knowledge and skills from the motorist.

Initially, buy a carburetor cleaner and you can get down to business.

- Disconnect the wiring harness from the sensor.

- Unscrew the two fasteners to remove the assembly.

- If necessary, completely clean the device from dirt on the conical needle and spring.

- Do not bypass the seat on the throttle assembly, it also needs to be cleaned. At the end of the procedure, put everything in its place.

- If nothing has changed after the cleaning measures carried out, all the symptoms of breakdowns remain, then the best way out is to simply replace the regulator.

The process of replacing the sensor is also quite simple:

- Disconnect battery power.

- Disconnect the power supply from the regulator.

- Loosen the fixing screws and remove the sensor.

- Installing a new device is done in the reverse order.

The idle speed controller is designed to stabilize the speed generated by the engine. A logical question arises: is the presence of this device so important and necessary? And also is it possible to do without it at all and how to properly carry out repairs in the event of a malfunction. The whole operation of the car depends on this device.

In order to understand what workflows the idle speed controller affects and why it becomes necessary to regulate its operation, it is necessary to have an idea of \u200b\u200bwhat are the principles of its operation.

Principle of operation

It is very important that the fuel and air are in certain ratios. Since with deviations of one or another indicator, the combustion process will not be perfect or will be completely absent. The main task of the idle speed regulator is to regulate the amount of air supplied at the time of being in idling mode. The supply does not occur through the throttle, as it opens at the moment of impact on the gas pedal.

The idle speed controller consists of a stepper motor, as well as a spring-loaded conical needle. In order to regulate the amount of air when the car is idling, it is necessary to change the cross section in the passage channel using the regulator. Simultaneously with the IAC, a special sensor operates, which records the amount of air. In turn, the controller supplies fuel.

Probably, most people who are not privy to the intricacies of the car, when they mention the phrase “idle”, think that this is the simplest and easiest mode of car operation, but this is far from the case. This mode is the most tiring for the engine, since it is very difficult to work at low speeds. And there are reasons for this:

The reason for the above processes is the low rate of supply of air-enriched fuel to the exhaust system. As a result, the mixing reaction occurs at an insufficient level and the level of efficiency is significantly reduced. Of course, with proper adjustment, the IAC will work for a very long time, but often malfunctions in the operation of this device are not uncommon. Most often, bad wiring is to blame. The installation of the IAC of a mechanical sample has earned quite a lot of popularity.

Attention! Thanks to the mechanical PPX, a significant reduction in exhaust toxicity can be achieved.

The most common idle problems

The possible occurrence of malfunctions associated with the operation of the idle speed controller must be taken with all seriousness, since they can lead to terrible and undesirable consequences. There are a number of specific symptoms that indicate that there is a problem with the idle speed sensor. These include:

You need to know how to check the idle speed sensor, since some signs of failure may indicate a malfunction of other parts of the car.

Causes of problems

There are many reasons that could lead to this malfunction. You should not waste a lot of time guessing, but you need to fix the problem as soon as possible. After all, long-term operation of the car with it can lead to more serious problems with the engine. There are two most common causes of malfunctions:

- wear of the guide needle;

- broken contacts in the middle of the sensor housing.

Checking the health of the regulator

Before starting the process of checking the idle speed controller, it is necessary to ensure the immobility of the vehicle, that is, tighten the handbrake and place shoes under the wheels. Consider the simplest and most affordable methods of diagnosing.

The device is removed from the common electrical circuit and the voltage is checked using a voltmeter. When the ignition is turned on, the resulting voltage should not go beyond the standard limits, that is, 20 volts. If the voltage is much lower - a malfunction with battery charging, if not - it is worth checking the entire circuit.

The resistance level should be checked. It should not exceed 53 ohms.

Attention! If the operation of the idle speed regulator is ideal, then the voltage indicator will be very high.

If you turn on the ignition and attach a power block to the idle speed controller, then the sensor needle should change its position, if not, then this indicates a malfunction.

It is possible that the main malfunction is in the operation of the IAC itself. With certain skills and knowledge, you can replace a faulty idle speed controller on your own, without the help of car service workers.

Regulator replacement

In order to adjust the idle speed controller in carburetor-type cars, there are special screws that allow manual replacement. But you will need additional devices such as a tachometer and a gas analyzer. In general, the process of replacing the idle speed controller on these vehicles is characterized by a certain complexity.

But on new-style vehicles, this procedure can be done much easier and faster. True, you will have to steadily follow some tips and recommendations:

There is one small but important nuance that concerns the repair of the idle speed controller. It is simply not provided. Some malfunctions can be eliminated by surface treatment with special chemicals. For example, WD-40 or carburetor cleaner.

Important! All cleaning procedures must be carried out as carefully as possible so as not to damage the device.

Acquisition of a regulator

The unit, in which the vibration of the needle is not felt, cannot be repaired. In this case, in order not to waste time on meaningless resuscitation efforts, you just need to get rid of it. You don't need to spend a lot of money to buy a new sensor.

Advice! Domestic sensors are considered the best option in terms of price and quality.

![]()

In specialized stores, sales consultants will help you decide on the choice of sensor. If there is any doubt about a new type of device, then it is best to take the old sensor with you as a sample and purchase just such a model.

It is very important to buy an original device, and not a cheap fake. It is worth paying attention to all the inscriptions and holograms on the packaging. If there are spelling errors or other suspicious points, then it is better to visit another store and choose a device that is not in doubt.

Buying is best done in trusted places. For greater guarantees, you can check the availability of quality certificates for the specified unit. Also, do not forget about the check. It must always be taken, as it is your guarantee.

In the case when in the operation of the car in idle mode, violations are noticed that are not characteristic of the operation of the engine, such as a sharp change in speed, then it is necessary to carry out diagnostics in order to identify the cause of these malfunctions. If you do not find and fix the problem in time, the situation may worsen. Do not rely on the lack of time for repairs, because it will not take much of it.

Replacing the idle speed sensor is shown on the example of a VAZ 21103 car:

The idle speed sensor (also: idle speed controller) is an element of the car's intake system designed to stabilize the idle speed (XX). This node plays a key role in the stable operation of the entire power unit.

Operating principle

The fuel must be optimally mixed with the air masses. Then the engine will produce the declared power. In case of receipt of an unbalanced fuel-air mixture into the combustion chamber, ignition is weak or completely absent. The idle speed sensor regulates the supply of air masses at the idle, thereby supplying a high-quality mixture to the cylinders. At the same time, the valve throttle valve is in the closed state.

Device

The regulator has in its design:

The sensor changes the size of the cross-sectional gap in the intake duct in order to adjust the incoming amount of air masses at the time of engine operation at idle. Together with the IAC, another measuring device is working, the task of which is to calculate the amount of incoming air, and the controller supplies air flows.

Idling (XX) on a cold one is the most difficult for a power unit for a number of reasons:

- costs are needed to heat the fuel and oil to working condition. Fuel that has not reached the desired condition is not able to ensure the correct operation of the power plant;

- low efficiency. Unlubricated (cold engine oil very thick and viscous) engine parts move tight against each other. Also, there is a strong difference in pressure between the intake / exhaust manifolds, which does not contribute to the high-quality combustion of the combustible mixture;

- Exhaust gases contain a high concentration of carbon dioxide.

The worse the rate of supply of the fuel-air mixture to the exhaust system, the more pronounced the above factors. Therefore, it is very important to keep the IAC in good condition. The main cause of a node malfunction is wiring, and therefore a mechanical idle sensor is widely popular. The main advantage of the device is the reduction of harmful emissions into the atmosphere.

Basic problems

Nagar is one of the main reasons for the incorrect operation of the regulator

Frequent malfunctions (symptoms) that the regulator suffers from:

- the operating speed of the engine jumps;

- when you turn on the neutral gear (XX), the speed does not change;

- when on-board equipment and electronics are activated, the speed drops;

- if you press the accelerator on the idle, the car stalls.

Causes

The above signs are indicative of possible malfunction RHH. Causes of failures can be as follows:

- Worn guide needle.

- The idle speed sensor has broken contacts in the housing.

- Sensor contamination.

Diagnostics

To check how the regulator works, it is necessary to fix the car in place with the parking brake and wheel chocks. There are several simple ways to diagnose IAC, but first you need to remove the part from the electrical link.

Replacement

To replace the regulator you need:

Calibration

New item needs tuning. After installing the new IAC, turn on the ignition for 5-10 seconds. Then we start the internal combustion engine and let it idle for about a minute. We turn off the engine. Then we start again and check the number of revolutions on the tachometer. You may have to repeat the process several times.

Buying a new node

If the sensor does not respond to needle vibrations, all signs of a necessary replacement with a new one. It makes no sense to reanimate the old node, since replacing it with another one will significantly save nerves and time, and it will be inexpensive in terms of money.

An idle sensor from a domestic manufacturer is optimal in terms of price / quality ratio, so it makes no sense to purchase an imported part.

Part cleaning

Device XX is cleared as follows:

If the part has an oil coating, additional cleaning of the throttle valve is required. The spring-loaded conical needle is cleaned with WD-40.

If cleaning did not help, the problem may be:

- in a broken wire. It is necessary to solder the wires, and the soldering area is degreased with alcohol. After that, a layer of varnish is applied (to prevent corrosion of contacts);

- wear of the taper needle guides. RHH is changing.

Despite the fact that the signs of a malfunction of the IAC are similar to the breakdowns of many other elements of the injection engine, some symptoms directly indicate a malfunction of the idle speed sensor. Consider how to diagnose with your own hands and determine the faulty regulator.

Signs of breakdown

Symptoms of a malfunctioning IAC:

Role in engine operation

To correctly recognize a regulator failure, you need to understand how the IAC works. Details and short process we have already considered diagnostics, so now we will focus only on the role in the operation of the engine.

In the life support system of the internal combustion engine, the idle sensor is used to regulate the supply of air passing by the throttle valve (through the bypass channel, the beginning of which is located in front of the throttle valve). When many electricity consumers are turned on at once, the load on the generator and, as a result, on the motor itself increases. To maintain a stable idle and battery charging voltage, the IAC opens the channel slightly, allowing more air into the internal combustion engine. In the same way, increased revolutions are realized when the internal combustion engine warms up.

Breakdowns

The main malfunctions of the idle speed controller:

- power failure, which can be caused by problems with electrical wiring, oxidation of contacts in connectors. With an unreliable connection, such a malfunction manifests itself periodically, which can complicate the diagnostic process;

- incorrect stroke of the rod due to contamination;

- breakdown of the electric motor;

- destruction of the sealing ring;

- rod wear. The movement of the curtain of a serviceable IAC occurs without biting, and there should be no slippage in the worm gear. To assess the condition of the rod and worm gear, we recommend that you see how to disassemble the IAC.

Among the above faults, rod contamination is the most common failure. During operation, mud deposits accumulate in the channels of the throttle assembly. If your car has not been cleaned for a long time throttle, most likely, problems with idling are associated with carbon deposits on the regulator rod. To check the IAC, it must be removed from the throttle assembly. As a flush, you can use a carburetor cleaner.

We recommend not to allow critical contamination of the regulator rod, since an increased load on the electric motor can damage the elements of the IAC control system. There have been cases of failure of the resistor of the electronic control unit (ECU) due to current overload of the control channel. Most likely, the increased load was provoked by the resistance of mud deposits and soot to the movement of the rod. The cost of a new resistor is ridiculous, but the prompt determination of this type of malfunction requires diagnostic equipment, as well as the qualifications of a master.

Diagnostics

There are three types of idle stabilization system:

- solenoid (only 2 pins in the connector);

- rotary (in the connector 3 pins);

- stepper (in the connector 4 pins).

In modern automotive industry, a stepper motor is most often used. At the heart of such a device is a ring magnet and 4 windings located at right angles to each other. Applying voltage to certain windings provokes the rotational movement of the rotor, which moves the rod (curtain) through the worm gear. To determine the working IAC, you need to check the condition of the motor windings. To do this, it is necessary to measure the resistance on the first two contacts and on the second two. For measurement, you will need the basic ones, as well as the device itself.

Options:

- on conclusions A, B and C, D should be between 40 and 80 ohms. The absence of resistance will indicate a break (for a VAZ, the value is usually 50-53 ohms);

- terminals A and C, A and D, B and C, B and D should have an infinitely large resistance, which will indicate the absence of a short circuit. A breakdown of this kind requires the purchase of a new IAC.

To determine a break in the power wires, you need to “ring out” the wiring with a multimeter in resistance measurement mode.

check engine

Modern injection engine control systems are able to register some idle speed sensor malfunctions. For example, consider the recorded deviations indicated in the error mask (the list of malfunctions in which the Check engine lights up) of the VAZ M7.9.7 engine control unit under EURO III toxicity standards:

- P1509 - IAC control circuit overload;

- P1513 - IAC control circuit, short to ground;

- P1514 - IAC control circuit, open or short to +12 V.

Also, when decrypting, the error code may appear as “IAC failure”. In this case, you should not immediately buy a new regulator, as the problem may be in the power wires.

You can read error codes through the diagnostic connector using a special scanner. Decryption codes can be easily found on the Web. In most cases, thorough cleaning helps delay replacement. You can most accurately and quickly determine a faulty idle speed controller by monitoring its operation in real time. This will require an oscilloscope, as well as the skills of a diagnostician. It will not work to apply voltage to the sensor terminals in order to watch the movement of the rod. The IAC is controlled by Pulse Width Modulation (PWM). On sale there are special devices for quickly checking the IAC of VAZ cars. But their cost is too high, if we talk about the frequency of use when repairing a personal car. Do-it-yourself testers are found on amateur radio forums.

In a simplified form, the idle speed controller allows the engine to run when starting and subsequent stops of the car, for example, at intersections. It supplies the missing amount of air to the injector fuel mixture for normal operation of a cold engine or when the car is stopped without stopping the engine.

The purpose of the IAC regulator

The idle speed controller is used exclusively in electronic ignition systems:

- the proportions of the fuel mixture in the injector are on-board computer;

- the amount of gasoline or diesel fuel for each cylinder is measured by the ECU;

- DPKV (crankshaft), TPS (throttle), DMRV (air), DD (detonation) sensors are installed in the electronic ignition, according to the signals of which the fuel pump is triggered and the ignition is distributed to specific cylinders;

- when the gas pedal is released, the fuel damper is completely closed, the proportions of the fuel mixture are violated, the combustion products are sucked back into the combustion chamber due to the pressure difference in the intake and exhaust manifolds.

Based on the results of the air sensor signals, the controller decides on additional enrichment of the fuel mixture with air, ignoring at this moment the readings of the throttle sensor.

The chip on the IAC transmits a signal from the ECU, a bypass channel opens in the idle speed controller, through which air passes in the injector or additional fuel in the diesel engine. The engine speed is evened out, the wear of the piston and crankshaft is reduced.

Operating principle

In carburetor engines, the problem of enriching the mixture when starting the internal combustion engine was solved by the starting handle and shims. With the advent of electronic ignition, this is done by the idle speed controller in conjunction with the rest of the sensors and the ECU. Its working principle is as follows:

- IAC calibration is performed by the ECU controller automatically after this sensor is detected in the system;

- in fact, the IAC is a stepper motor with a conical needle in a special hole in the throttle bypass channel;

- The IAC contact does not transmit any signals to the "brain" of the machine, but receives them from the controller, therefore it is not a sensor, but an actuator - an electrovalve;

- in turn, the on-board computer "sees" that there is not enough air in the fuel mixture according to the DMRV signals compared with the TPS signals;

- voltage is applied to the XX regulator, the needle leaves the channel, the missing amount of air enters the mixture for mixing.

In addition, the ECU receives signals about the temperature of the coolant and oil in the system. When starting in the cold season, it is necessary to warm up the engine to operating temperature in order to reduce wear on friction parts, so the IAC channel opens slightly to enrich the mixture to the injector, even without pressing the gas pedal by the driver.

At the time of start, the algorithm of work is as follows:

- the key is turned, the ignition is switched on;

- the stem extends to the stop, the needle closes the bypass channel;

- at the moment the rod rests against the calibration hole, the computer counts the steps back;

- voltage is applied to the windings, the valve returns to the open position.

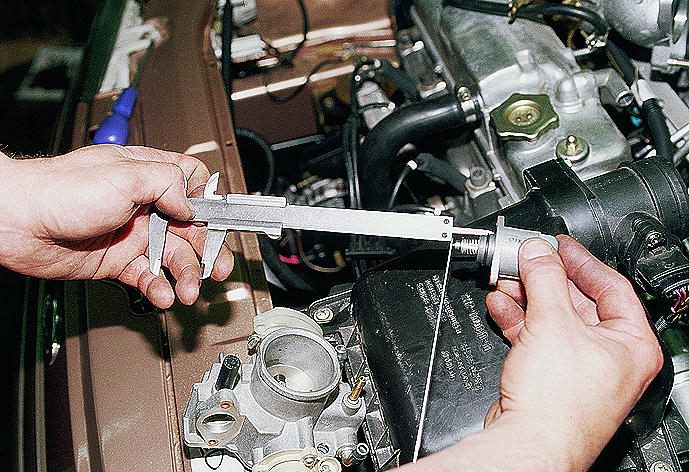

The number of reverse steps is programmed in the firmware of the device. For example, for Basch modifications on a warmed-up internal combustion engine, it is 50 steps, January - 120 steps, respectively. In total, the stroke of the rod is divided into 250 steps, the farther it is pulled out of the windings of the stepper motor, the more steps the ECU will count. When buying a new IAC, the distance from the seat flange to the rod needle should be exactly 23 mm.

Injector

For work injection engine pure gasoline is not suitable, therefore, a throttle valve with an individual sensor of its position at each moment of time is installed at the manifold inlet. When the engine is started or the machine is stopped with the engine running, the following occurs:

- the computer receives information about the revolutions of the motor shaft;

- analyzes how the motor works, that is, clarifies the intended purpose;

- then the readings of the throttle position sensor and air are compared, that is, the controller “understands” that the damper is closed, and a lean mixture enters the cylinders;

- the IAC valve opens, air is supplied bypassing the damper to maintain the speed at the programmed level

In fact, several devices of the electronic ignition system are involved in the process. If the machine stalls or symptoms of other problems are present, the diagnosis is made manually, because feedback(self-diagnosis) this device does not have.

There is no throttle in a diesel engine, the idle speed controller is useless, other methods of adjusting low speeds are used.

Design features

At the stage of the emergence of DHH, solenoid and rotary idle sensors were used. They had two positions, by analogy with the valve - Open / Closed, which reduced the efficiency of engine speed adjustments. These have now been replaced by a 4 step valve with step bypass flow adjustments.

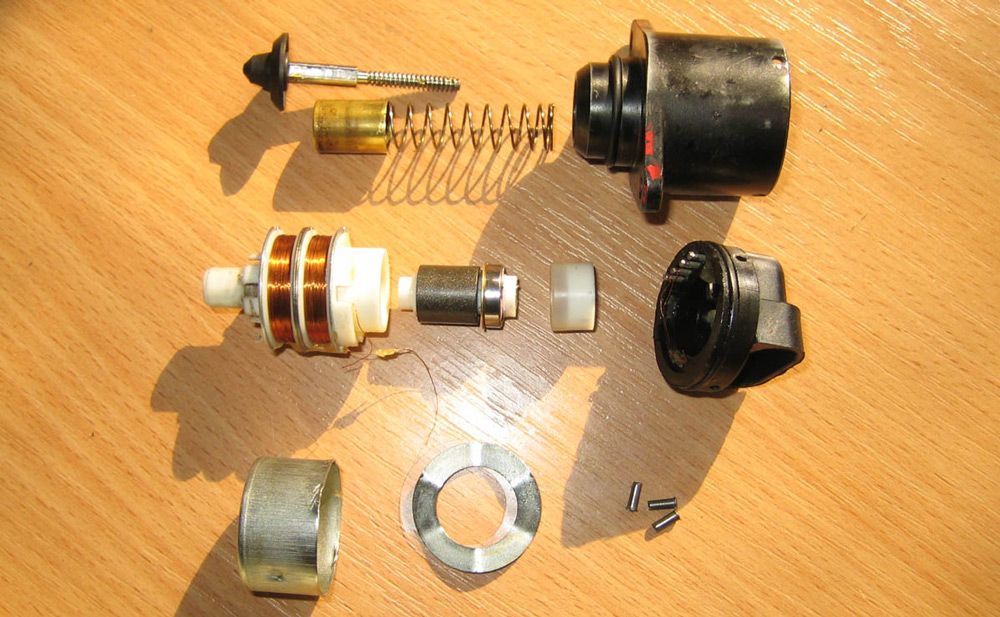

If you disassemble the IAC, you can see that it is assembled from four parts:

- stepper motor;

- four-position stem;

- spring;

- needle.

When voltage is applied to one of the four windings, the coil is magnetized, interacts with the magnetic ring, and moves the rod to one of four positions. Accordingly, the number of breakdowns of this electrical appliance is as limited as possible:

- the bypass channel is clogged;

- windings burn out;

- the needle or spring breaks.

The sensor is positioned by manufacturers as a “consumable”, that is, it is considered conditionally not repairable. It is cheaper to replace the whole than to disassemble and repair individual parts. If they are not on sale, you need to grind them yourself.

However, the first reason can be eliminated on our own - with the connector disconnected, we remove the regulator in order to clean the bypass channel with a universal WD-40 spray.

Installation location

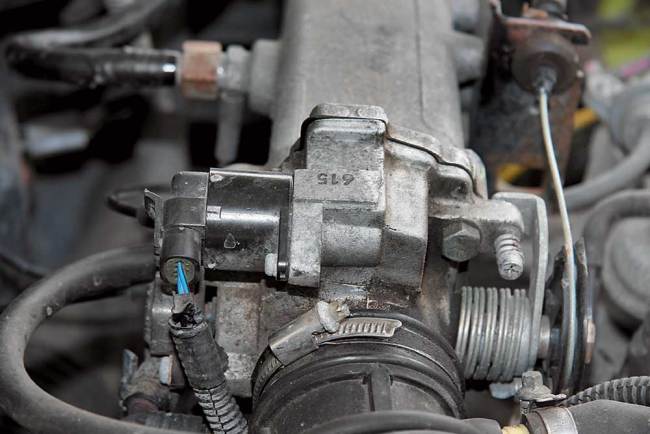

Knowing the principle of operation of the IAC, it is very simple to determine where the valve is located - near the throttle valve and its spatial position sensor TPS.

It is extremely rare that the sensor is glued to the damper body with varnish, in other cases the device is fixed with two screws, for which there are mounting holes. The main task of how to adjust the IAC valve with your own hands when installing the IAC is precisely to ensure a distance of 23 mm from the needle to the landing flange.

Before you remove the regulator for replacement, you should study the markings. IACs with markings 01/03 or 02/04 are considered interchangeable. If you put 02 instead of 01 or 03, the device will not work correctly.

The idle speed controller comes with a single harness of four wires from the ECU. Below is a diagram of the distribution of the motor windings.

The main problem is the diagnostics of the sensor on its own. Simply applying voltage to its terminals to check the performance will not work, since the ECU does this impulsively. Windings burn very rarely, mechanical failures are more common, for example, a bent stem or a clogged bypass channel

In the service station, the sensor is checked on stands capable of reproducing the ECU impulse. Even with a multimeter, a motorist can only verify the integrity of the windings and the absence of a short circuit between them, nothing more.

Signs of failure

The main symptoms that the idle speed sensor is not working correctly are:

- revolutions in the parking mode are unstable;

- reduction in the speed of rotation of the crankshaft when any consumer is turned on (wipers, headlights, air conditioning, radio, heater);

- no increase in the shaft rotation speed when starting the internal combustion engine;

- engine stop when disengaging gear or changing gears.

Attention: These symptoms are not the cause of IAC failure by 100%, as they are similar to the failure of the TPS damper sensor. However, in the latter version, the Check error lights up, and the regulator idling it is not connected with the engine control system, it does not have self-diagnosis.

IAC Diagnostics

Ideally, the regulator diagnostics should be carried out on a stand that can reproduce the impulses of the on-board computer. In practice, this is expensive, budgetary verification methods are used. In any case, the algorithm of actions for initial stage same:

- the hand brake is tightened, recoil devices - shoes are installed under the wheels;

- disconnect the “-” terminal from the battery;

- knowing where the TPS and DMRV sensors are located, the location of the IAC is determined;

- the valve is disconnected from the on-board computer (the plug is pulled out of the connector).

The next steps are different for different verification methods.

Manual check

The easiest way to check the IAC in the electronic intake distribution system is manual diagnostics (an assistant is required):

- the IAC plug is disconnected from the connector;

- two screws are unscrewed, the device is dismantled;

- the regulator is reconnected to the computer, but remains in the hands of the master;

- the assistant starts the engine, the rod at this time should be completely drawn into the coils, then, having received an impulse from the computer, move forward for a certain distance.

In other words, the performance of the stem is checked, the owner makes sure that this part is not bent, does not jam inside the valve. However, this does not give 100% guarantees that this modification of the IAC is fully consistent with the controller ECU firmware. The needle comes out, but by an unknown amount. In the first case, the connector is checked, in the second - the plug, the marking is only on the plug.

At classic version checking “from simple to complex” this stage is the initial one, then you should check the integrity of the wires and coils, the condition of the bypass channel, and the wear of the needle. Only after these steps can you assemble a home-made stand with a pulsed voltage supply for complex diagnostics of the IAC.

Diagnostics with a multimeter

At this stage, you will need an IAC tester, which is checked by this device in two modes:

- with an ohmmeter - when the probes of the multimeter close contacts C - D and A - B, the resistance should be 40 - 80 Ohms, D - C and A - D should be equal to infinity;

- voltmeter - when the ignition is turned on, the voltage reaches 12 - 20 V.

Attention: IAC setting is done automatically on-board computer after each connection of the device plug to the socket. After dismantling, it is recommended to lubricate the bypass channel with WD-40 spray to clean it. This measure is preventive, even in the absence of contamination of the bypass channel, in the gap of which the regulator is located.

Impulse test on a homemade stand

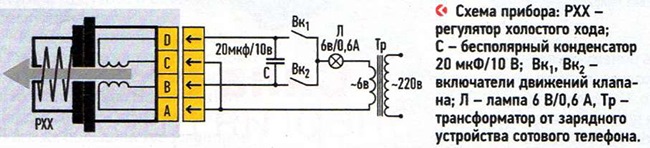

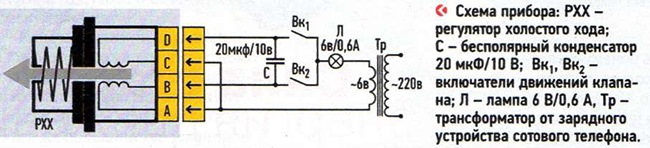

Since the stand costs 1,500 - 1,800 rubles, and the regulator 300 - 500 rubles, buying a device is not economically beneficial for an ordinary user. simple circuit without microchips is shown below:

- it uses 6 V charging from any mobile device;

- plug sockets are commercially available;

- first you need to disconnect the IAC from the onboard controller, then the stroke of the rod is checked;

- the bright glow of the lamp in the diagram indicates a malfunction of the stem itself;

- if the lamp burns to the floor of the glow, the node is considered serviceable.

The use of a cleaning agent will restore the performance of the stem, but only in case of blockages. If this part is bent, the entire regulator must be replaced.

Main malfunctions

The above symptoms of a malfunction usually occur in the following cases:

- the bypass channel of the throttle valve is clogged with dirt;

- the integrity of the wires or coils is broken;

- The ECU firmware does not match the IAC modification.

Checking the above methods reveals all the causes of the problem. Each time the regulator or throttle assembly is disassembled, it is recommended to clean the IAC with special fluids / sprays.

Cleaning the needle and bypass

To provide access to the valve parts, IAC removal is required according to the technology:

- disconnecting the block from the connector;

- cleaning the contacts of the connector and plug with a cotton swab moistened with WD-40;

- unscrewing the screws with a curly screwdriver;

- remove the regulator to check the condition.

Attention: It is not necessary to disassemble the regulator, it is enough to spray the spring and the stem with the needle with WD-40 spray, wait for it to dry, while cleaning the throttle bypass channel.

The adjustment is made by the onboard network controller itself. However, for stable operation of the engine, the distance from the mounting flange to the protruding cone of the needle should be checked. By default, it should be 23 mm.

The nuances of choosing an idle speed sensor

The original idle speed sensor is marked as XX-XXXXXXX-XX. The last two digits indicate the compatibility label:

- odd (01 and 03) interchangeable, even (02 and 04) also interchangeable;

- these groups are not interchangeable with each other, that is, instead of the “native” 02, valve 01 or 03 cannot be operated.

Even in the original regulators, it does not hurt to additionally lubricate the IAC with a mixture of lithol and WD-40 (spring and stem). Since do-it-yourself IAC replacement is in demand by motorists, there are counterfeit regulators that can be identified by signs:

- there are no distinctive marks on the packaging;

- yellow sticker on the body without a frame;

- dark colored needle tip;

- thin black o-ring instead of thick red o-ring;

- body rivets do not have caps with a diameter of 3 mm;

- white spring instead of black product with frequent winding;

- case shorter by 1 mm.

Since installation is always done on your own, lubricate the stem and spring additionally to increase the service life of the IAC and the entire engine.

Thus, it is better to have an IAC solenoid valve at a price of 300 - 500 rubles in stock in order to replace it in the field to normalize the idle speed of the internal combustion engine. These diagnostic methods will allow you to determine the malfunction of the regulator and the clogged throttle bypass channel.