Water computer cooling systems. ¡ - Water Cooling Guide (CBO)

If you bought a powerful new computer, then it will consume a lot of electricity, as well as make a lot of noise, which is a very unpleasant and very significant drawback. Sufficiently bulky system units (for air circulation), with large coolers, in this case are not the best option, so today we will tell you about an alternative option - water cooling for a computer (specifically, about its types, features and, of course, advantages) .

Why is it necessary water cooling?!

As we have already said, ordinary computer fans create a lot of noise, and besides, even despite their high power, they are not able to rationally remove heat generated by computer components from the system unit, which in itself increases the risk of failure of any element from overheating.

Under these conditions, manufacturers turned their attention to liquid cooling systems for computer parts. A check of many such systems as a whole shows that a liquid computer cooling system has the right to exist due to a number of indicators that distinguish it favorably from an air system.

Advantages and principles of water cooling

No water cooling required large volume system unit in order to provide better air circulation in the system unit itself. Among other things, it makes much less noise, which, by the way, is also an important factor for people who, for one reason or another, spend a lot of time at the computer. Any air system, even the highest quality, with all its advantages, during its operation continuously creates a stream of air that walks around the entire system unit, in any case increases the noise in the room, and for many users a low noise level is important, since The constant hum is very annoying and annoying. The software independently regulates the pressure of the fluid flow in the system, depending on the intensity of the heat dissipation of the processor and other computer components. That is, the system can automatically increase or decrease the efficiency of heat dissipation, which provides continuous and accurate control of the temperature regime, both for any individual element (whether it be a processor, video card or hard drive), and throughout the entire space of the system unit. Thus, the use of liquid cooling also eliminates the disadvantage of any air system, when computer parts are cooled mainly by air from the system unit, which is continuously heated by the same parts and does not have time to leave the unit in a timely manner. With liquid, such problems are excluded. Such a system is able to cope with its tasks much more efficiently than any air cooling.

Also, in addition to the high level of noise, air cooling of the computer leads to a large accumulation of dust: both on the cooler fans themselves and on other components. In turn, this has a very negative effect both on the air in the room (when an air stream with dust leaves the system unit), and on the speed of all components, on which all the dust settles.

Types of water cooling according to the place of cooling

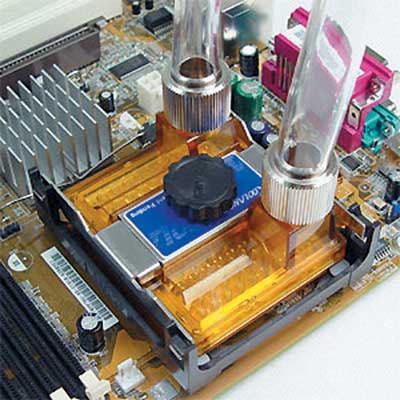

- Of greatest importance in any such system is cpu heatsink. Compared to traditional coolers, a processor heatsink with two tubes connected to it (one for the liquid inlet, the other for the outlet) looks very compact. This is especially pleasing, because the cooling efficiency of such a radiator is clearly superior to any cooler.

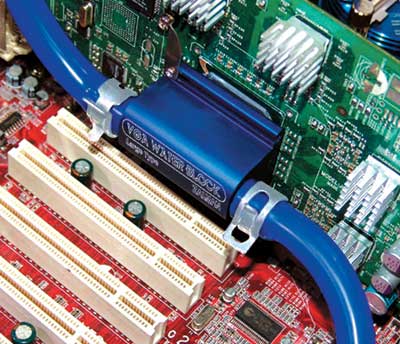

- Video card graphics chips they are cooled in the same way as the processors (in parallel with them), only the radiators for them are smaller.

- Liquid cooling is no less efficient. winchester. For this, very thin water radiators have been developed, which are attached to the upper plane of the hard drive and, due to the largest possible contact area, provide good heat dissipation, which is impossible with conventional air blowing.

The reliability of the entire water system depends most of all on the pump (pumping pump): stopping the circulation of the liquid will instantly cause the cooling efficiency to drop to almost zero.

Liquid cooling systems are divided into two types: those with a pump and those without it - pumpless systems.

1st type: liquid cooling systems with a pump

There are two types of pumps: those with their own sealed housing, and simply immersed in a reservoir of coolant. Those that have their own sealed housing, of course, are more expensive, but also much more reliable than those immersed in a liquid. All liquid used in the system is cooled in a heat exchanger radiator, to which a low-speed cooler is attached, which creates an air flow, which cools the liquid flowing in the curved radiator tubes. The cooler never develops a high rotational speed, and therefore the noise from the entire system is much less than from powerful coolers used in air cooling.

2nd type: pumpless systems

As the name implies, there is no mechanical supercharger (i.e. pump) in them. Liquid circulation is carried out using the principle of an evaporator, which creates a directed pressure that moves the coolant. A liquid (with a low boiling point) continuously turns into vapor when it is heated to a certain temperature, and vapor into a liquid when it enters the radiator of the heat exchanger-condenser. Only the heat generated by the cooled element causes the liquid to move. The advantages of these systems include: compactness, simplicity and low cost, since there is no pump; minimum moving mechanical parts – provides low noise level and low probability of mechanical failures. Now about the disadvantages of this type of computer water cooling. The efficiency and power of such systems are significantly lower than those of pump systems; the gas phase of the substance is used, which means that a high tightness of the structure is needed, because any leakage will lead to the system immediately losing pressure and, as a result, becoming inoperable. And it will be very difficult to notice and fix it.

Is it worth installing water cooling on a computer?

The advantages of this type of liquid cooling are: high efficiency, small size of computer chip heatsinks, the possibility of parallel cooling of several devices at once and not high level noise - in any case, lower than the noise from a powerful cooler of any air system. Actually, all this explains that laptop manufacturers were among the first to use liquid cooling. Their only drawback, perhaps, is only the complexity of installation in system units that were originally designed for air systems. This, of course, does not make the installation of such a system on your computer impossible, it will simply be fraught with certain difficulties.It is likely that after some time in computer technology there will be a transition from air cooling systems to liquid systems, because in addition to the difficulties in installing such structures on today's system unit cases, they do not have any other fundamental disadvantages, and their advantages over air cooling very, very significant. With the advent of suitable cases for system units on the market, the popularity of these systems is likely to grow steadily.

Thus, site experts have nothing against these cooling systems, but rather advise them to give preference if circumstances so require. Only when choosing one or another system, you do not need to save, so as not to get into a mess. Cheap water cooling systems have low cooling quality and a fairly high noise level, which is why, when deciding to install water cooling, count on a fairly high amount of wastage.

Gone are the days when a computer did not require specialized cooling systems. As the clock speeds of the central and graphic processors increased, the latter first began to acquire passive radiators, and subsequently required the installation of fans. Today, not a single PC can do without special coolers for cooling the processor, video card, and northbridge of the chipset. Often, specialized coolers are installed on hard drives, and additional fans are placed in the case itself for forced convection.

There is nothing to do you can’t argue with the laws of physics, and the growth of clock frequencies and PC performance is inevitably accompanied by an increase in power consumption and, as a result, heat generation. This, in turn, forces manufacturers to create new, more efficient cooling systems. For example, not so long ago, cooling systems based on heat pipes began to appear, which are now widely used to create laptop cooling systems.

Along with traditional cooling systems based on radiators with fans, liquid cooling systems are becoming more common, which are used as an alternative to air systems. However, one important note must be made here: despite all the manufacturers' assurances about the need to use liquid cooling systems to ensure normal temperature conditions, in reality this condition is not at all necessary during normal PC operation.

Actually, all modern processors are designed specifically for air cooling, and for this a regular cooler supplied in a boxed version of the processor is quite enough. Video cards are generally sold with a stock air cooler, eliminating the need for alternative cooling solutions. Moreover, I will take the liberty of asserting that modern air cooling systems have a certain reserve and that therefore many manufacturers even reduce the fan speed without sacrificing performance, thus creating low-noise sets for cooling processors and video cards. Recall at least the ZALMAN silent PC kits - these devices use fans with low speeds, which, nevertheless, are quite enough.

The fact that traditional air cooling systems quite cope with the task assigned to them is evidenced by the fact that not a single domestic PC manufacturer installs liquid cooling systems in their serial models. Firstly, it is expensive, and secondly, there is no special need for it. And the scary stories that as the temperature of the processor rises, its performance drops, which is due to Throttle technology, are, by and large, fiction.

Why, then, do we need alternative liquid cooling systems at all? The fact is that so far we have been talking about the normal operation of the PC. If we look at the problem of cooling from the standpoint of overclocking, it turns out that standard cooling systems may not be able to cope with their tasks. This is where more efficient liquid cooling systems come to the rescue.

Another application of liquid cooling systems is the organization of heat removal in a limited space of the case. Thus, such systems are used in the case when the case is not large enough to organize effective air cooling in it. When the system is cooled by a liquid, such a liquid circulates through flexible tubes of small diameter. Unlike air lines, fluid tubes can be configured in almost any configuration and direction. They occupy a much smaller volume than air channels, with the same or much greater efficiency.

Examples of such compact cases where traditional air cooling may not be effective are various options barebone systems or laptops.

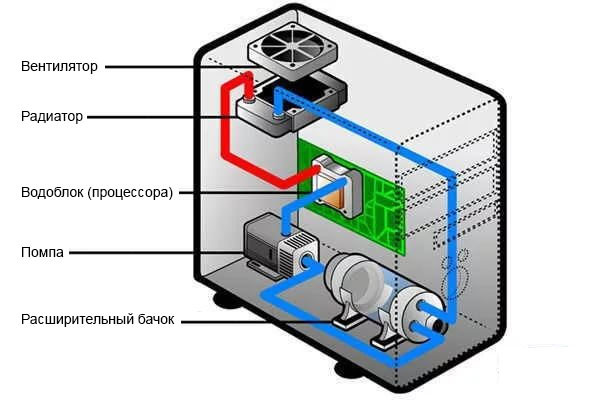

The device of liquid cooling systems

Let's look at what liquid cooling systems are. The fundamental difference between air and liquid cooling is that in the latter case, instead of air, a liquid is used to transfer heat, which has a higher heat capacity than air. To do this, instead of air, a liquid is pumped through the radiator - water or other liquids suitable for cooling. The circulating liquid provides a much better heat dissipation than the air flow.

The second difference is that liquid cooling systems are much more compact than traditional air coolers. That is why laptop manufacturers were the first to use liquid cooling on mass-produced devices.

In terms of the design of the forced liquid circulation system in a closed loop, liquid cooling systems can be divided into two types: internal and external. At the same time, we note that there is no fundamental difference between internal and external systems. The only difference is which functional blocks are inside the case, and which are outside.

The principle of operation of liquid cooling systems is quite simple and resembles the cooling system in automobile engines.

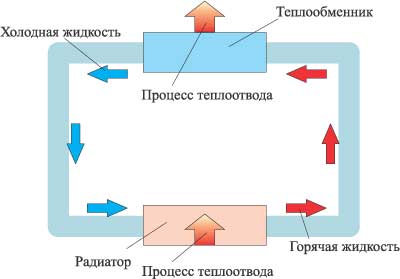

Cold liquid (usually distilled water) is pumped through the radiators of cooled devices, where it heats up (removes heat). After that, the heated liquid enters the heat exchanger, in which it exchanges heat with the surrounding space and cools. For efficient heat exchange with the surrounding space, heat exchangers usually use fans. All components of the structure are interconnected by flexible silicone hoses with a diameter of 5-10 mm. In order to make the liquid circulate through a closed case, a special pump is used - a pump. The block diagram of such a system is shown in fig. 1.

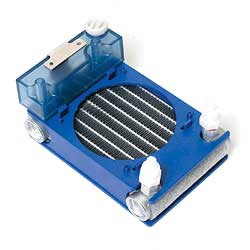

Through liquid cooling systems, heat is removed from the central processing units and graphics processors of video cards. At the same time, liquid radiators for graphics and central processors have some differences. For GPUs, they are smaller in size, but fundamentally nothing special from each other. The efficiency of a liquid radiator is determined by the area of contact of its surface with the liquid, therefore, to increase the contact area inside the liquid radiator, fins or columnar needles are installed.

In external liquid cooling systems, only a liquid radiator is placed inside the computer case, and the coolant reservoir, pump and heat exchanger, placed in a single unit, are taken out of the PC case.

Internal liquid cooling systems

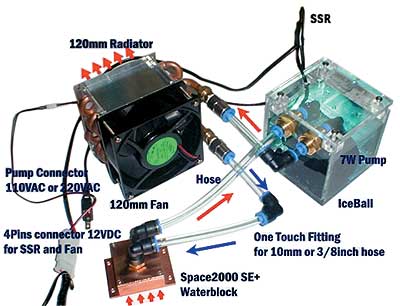

A classic example of an internal liquid cooling system is the CoolingFlow Space2000 WaterCooling Kit from CoolingFlow (www.coolingflow.com), shown in Figure 1. 2.

Rice. 2. CoolingFlow Space2000 WaterCooling Kit

This system is intended only for cooling the processor on which the Space2000 SE+ waterblock liquid radiator is installed. The pump is combined with a 700 ml liquid reservoir.

Another example of a liquid cooling system with a pump installed inside a PC case is the Poseidon WCL-03 system (Fig. 3) from 3RSystem (www.3rsystem.co.kr).

The Poseidon WCL-03 system is designed for liquid cooling of the processor or chipset.

Poseidon WCL-03 consists of two functional blocks. The first block is a water tank with dimensions of 90X25X30 mm, combined with a heat exchanger radiator sized 134X90X22 mm (Fig. 4), and the second is a liquid processor heatsink combined with a pump (Fig. 5). The processor heatsink is made of aluminum and measures 79X63X8mm and weighs 82g.

Rice. 4. Water tank combined with Poseidon heat exchanger radiator

Rice. 5. CPU heatsink combined with Poseidon WCL-03 system pump

Another example of an internal liquid cooling system is Evergreen Technologies' TherMagic CPU Cooling System (Figure 6). As the name implies, this system is designed to cool the processor, and it consists of two functional blocks: a liquid processor heatsink made of copper, and a heat exchanger unit combined with a pump.

Rice. 6. TherMagic CPU Cooling System

The heat exchanger is a rather impressive square-section plastic case, on both sides of which there are fans that drive air through the device.

Inside the heat exchanger housing there is a miniature pump that pumps liquid through the system, and a large copper radiator with large area fins (Fig. 7).

The heat exchanger is attached to a standard seat designed for an additional fan in the computer case; hot air is blown out.

External liquid cooling systems

Internal liquid cooling systems have one drawback: mounting them inside a case can cause problems, since standard cases are initially designed specifically for air cooling systems. Therefore, those who prefer an internal liquid cooling system will have to select the appropriate case. External liquid cooling systems do not have this disadvantage.

A classic example of an external liquid cooling system is the Aquagate ALC-U01 system from Cooler Master (www.coolermaster.com). This system is a separate block made of aluminum with dimensions of 220x148x88 mm (Fig. 8).

![]()

This unit can be installed either inside the computer, occupying two 5.25-inch bays, or separately from the system unit (for example, on top) (Fig. 9).

Naturally, even with the location external to the body, the Aquagate ALC-U01 system remains connected to the body with two flexible hoses for pumping water. The very same processor cooling system (liquid radiator) looks quite traditional (Fig. 10).

Inside the aluminum case of the Aquagate ALC-U01 system there is a heat exchanger, a pump and a liquid reservoir. The heat exchanger consists of the heatsink itself and an 80mm fan that blows hot air out of the heatsink. The fan speed is controlled by a temperature sensor built into the system and can be 4600, 3100 and 2000 rpm.

The second example of an external liquid cooling system that does not allow for indoor installation is the Exos-Al system (Fig. 11) from Koolance (www.koolance.com)

The dimensions of this system are 184X95X47 mm. Inside the Exos-Al outdoor unit there is a massive heat exchanger radiator (Fig. 12), hot air from which is sucked out by three fans. In addition, the block has a pump and, of course, a water tank.

The Exos-Al liquid cooling system can be used for both CPU and GPU cooling. Only liquid radiators used for cooling are different. The heat sink for the central processor is shown in fig. 13, and the heatsink for the GPU is shown in fig. 14.

Note that Koolance produces not only external liquid cooling systems, but also entire cases with a built-in liquid cooling system based on the Exos-Al system. An example of such a case is shown in Fig. 15.

Rice. 15. Koolance PC2-C case with built-in liquid cooling system

Of course, such a well-known company as ZALMAN (www.zalman.co.kr), specializing in the production of cooling systems, could not ignore liquid cooling systems and also presented its solution on the market - an external RESERATOR 1 system (Fig. 16) .

Rice. 16. External liquid cooling system ZALMAN RESERATOR 1

In its design, this system is very original and is not similar to any of the above. In fact, this is a kind of "water pipe" installed next to the PC system unit.

The RESERATOR 1 system includes several functional blocks: the heat exchanger itself (Fig. 17) with a built-in pump (Fig. 18) and a liquid reservoir, a ZM-WB2 processor liquid radiator (Fig. 19), a liquid flow indicator (Fig. 20) and an optional liquid heatsink for the ZM-GWB1 GPU (Fig. 21).

Rice. 17. Heat exchanger with built-in pump and liquid reservoir of the RESERATOR 1 system

Rice. 18. Pump installed at the bottom of the RESERATOR 1 heat exchanger

The external heat exchanger of the RESERATOR 1 system has a height of 59.2 cm with a diameter of 15 cm. Including diverging radiator fins, its total surface area is 1.274 m2.

The liquid flow indicator is included in the liquid circulation circuit and is intended for visual control of the liquid flow. When the liquid circulates through the circuit, the damper inside the indicator begins to vibrate, which indicates the normal state of the system.

ZM-WB2 processor liquid heatsink has an all-copper base and can be used for any processors and sockets (Intel Pentium 4 (Socket 478), AMD Athlon/Duron/Athlon XP (Socket 462), Athlon 64 (Socket 754)).

Another example of a liquid external cooling system is the Aquarius III Liquid Cooling system (Fig. 22) from the notorious company Thermaltake (www.thermaltake.com).

Rice. 22. External liquid cooling system Aquarius III Liquid Cooling

This system in many ways resembles the Aquagate ALC-U01 system discussed above. Inside the 312X191X135mm aluminum housing of the Aquarius III Liquid Cooling unit are a water pump, a heat exchanger with an 80mm fan and a liquid reservoir.

The pump is installed inside a small fluid reservoir. Depending on the temperature of the liquid, the pump is able to change the rotor speed (the value can be monitored in the same way as for a conventional cooler).

To supply silicone tubes through which liquid circulates, a corresponding plug is supplied in the kit (Fig. 23).

The tank is made of transparent plastic with LED illumination from the inside. For visual control of the pump's performance, two white plastic balls are placed inside the tank, which rotate during operation. Four tubes are connected to the reservoir with the pump. Two of them are from an additional water tank, through which you can add water to the system, and then judge its amount in the circuit. According to the instructions, the tank should be installed outside the case, but this is not necessary - you only need to monitor the water level in the pump monthly according to the appropriate marks and add liquid as needed.

The liquid heatsink of the processor (Fig. 24) is completely made of copper and is universal, that is, it can be installed on any modern processor.

Rice. 24. Aquarius III Liquid Cooling Processor Liquid Cooling

The future of cooling systems

Despite all the efficiency of liquid cooling systems, it has already become clear that the day will inevitably come when the clock speeds of processors will reach that very critical value when the further use of traditional cooling systems will become impossible. Therefore, developers do not stop looking for fundamentally new, more efficient cooling systems. One of these promising developments, based on a discovery by scientists at Stanford University, is owned by Cooligy (www.cooligy.com).

Actually, the technologically new cooling system resembles a traditional liquid one. In any case, there is also a liquid radiator, a heat exchanger and a pump. The main difference lies in the principle of operation of the pump and the liquid radiator.

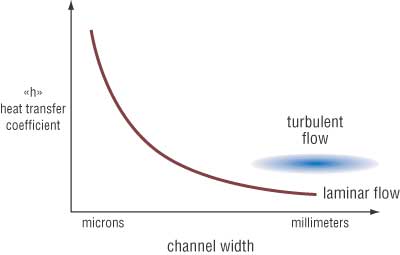

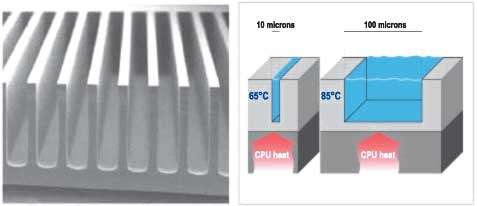

A liquid heat sink, called the Microchannel Heat Collector, is built into the silicon chip of the microcircuit (processor). Inside, the liquid radiator has a microchannel structure with a width of an individual channel of about 20-100 microns.

The idea of using a microchannel structure for efficient cooling of microcircuits was put forward as early as 1981 by Stanford University professors Dr. David Tuckerman and Dr. Fabian Pease. According to their study, the microchannel structure embedded in silicon allows 1,000 watts of heat to be removed from every centimeter of silicon surface. The efficiency of heat removal in a microchannel structure embedded in a silicon crystal is realized due to two effects. First, the heat removed from the silicon crystal is transferred over a very short distance, since the microchannels are located directly in the silicon crystal. Secondly, the heat transferred by the wall of the cold liquid microchannel is also transferred over a very short distance, since the diameter of the microchannel itself is very small. The result is very high ratio heat transfer of the microchannel structure, and depending on the width of the channel itself (Fig. 25).

As a result, the smaller the microchannel thickness, the more efficiently heat is removed and the colder the microchannel walls remain (Fig. 26).

Rice. 26. As the thickness of the microchannel decreases, the efficiency of heat removal increases

The second feature of the cooling system developed by Cooligy is the pump itself, which circulates liquid in a closed circuit.

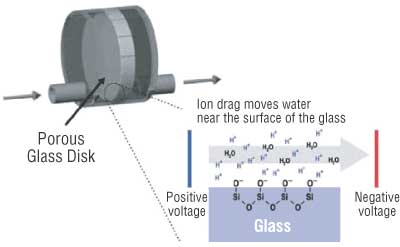

The principle of operation of this pump is based on the electrokinetic phenomenon, therefore such a pump is called electrokinetic (EK pump).

In an electrokinetic pump, liquid (water) passes through glass tubes, the walls of which have a negative charge (Fig. 27). In water, due to the electrolysis reaction, there is a certain amount of positively charged hydrogen ions, which will be displaced towards the negatively charged glass walls.

If an electric field is applied along such a glass tube, then positive hydrogen ions will move along the field, dragging the entire liquid with them. In this way, the liquid inside the glass tube can be made to move.

This series features unique fully water-cooled computers. All systems are created manually in a single copy. Crazy performance for the most demanding tasks like a virtual reality with ultra-high quality settings.

Introducing the fastest Hyper gaming PCs ever made

Hyper Concept are unique computers with a fully water cooled and extreme overclocking. The development of the Concept series computers is one of the most complex and lengthy in the history of HYPERPC.

Our experts had only one goal, to make best computer in the world!

The performance of these computers will simply shock you!

The specifications of these computers are truly impressive: the world's fastest Intel Core i7 Extreme processor overclocked to 5GHz, two of the most powerful NVIDIA GeForce gaming graphics cards in SLI mode, and all this is cooled by a unique water cooling system. No wonder water cooling has been on the minds of many computer enthusiasts for several years now.

Find out more about how we build exclusive water-cooled computers

What is a water cooling system?

A water cooling system is a cooling system that uses water as a heat transfer medium to transfer heat. Unlike air-cooled systems that transfer heat directly to the air, a water-cooled system first transfers heat to the water.

Who is a water cooling system suitable for?

If you are an ordinary user who spends 2-3 hours at the computer a day, who does not work with graphics, does not play games, does not overclock (overclock), is not fond of modding, then a standard air cooler will suffice for you. But if your computer is a way of life, or earnings, if you want maximum power with overclocking of the entire system, perfect silence, or maybe your computer is part of the interior, then water cooling is exactly what you need.

The CPU waterblock is a heat exchanger that transfers heat from the CPU to the coolant. The water block for the processor consists of a metal base that is in direct contact with the processor heat spreader, and a cover with holes to include it in the CBO circuit. To achieve maximum performance, the inner surface of the base has a complex structure.

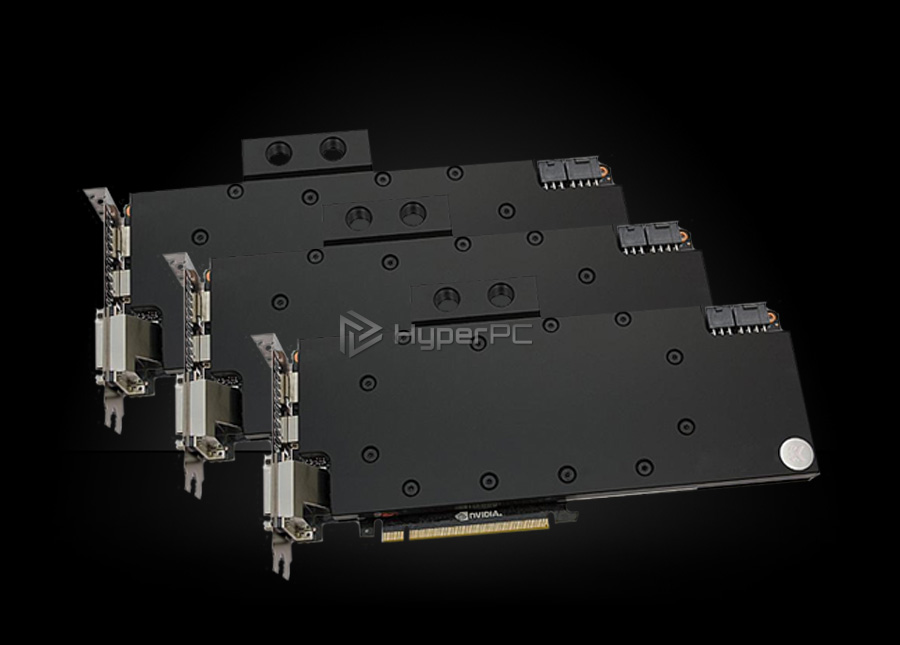

Water blocks for video cards are divided into two main types - a water block that covers only the chip and a water block with full coverage, which provides heat removal from all critical components of the video adapter at once. The base of such water blocks has a complex structure, which contributes to more efficient heat dissipation.

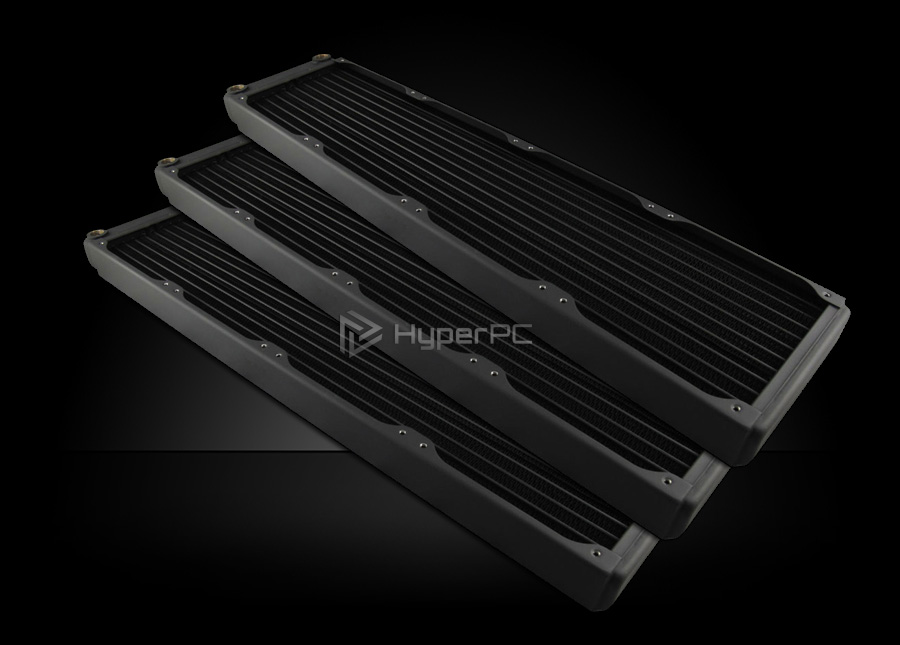

The radiator in the liquid cooling system is necessary to remove heat from the cooling circuit to the atmosphere. To do this, one or more large-diameter fans are usually installed on it. The size of the radiator is determined by the power to be removed from the cooling circuit.

The pump is an electronic pump that circulates the coolant in the cooling system circuit.

The reservoir serves to accumulate air from the cooling circuit and provide a supply of liquid. It also serves to equalize pressure - this is necessary because the liquid expands when heated.

The pump and reservoir can be made as a single device, or they can be separate LSS units.

Fitting (English fitting, from fit - to fit, mount, assemble) - the connecting part of the pipeline, installed in places of its branches, turns, transitions to a different diameter, as well as, if necessary, frequent assembly and disassembly of pipes. Fittings also serve to hermetically seal the pipeline and other auxiliary purposes.

The circuit of the liquid cooling system is represented by tubes or hoses connecting all its components into a single mechanism. Proper circuit design is critical to maximizing the efficiency of the entire WTO, and our engineers put all their years of experience into this task. Also, the contour can be one of key elements design of the entire system.

The coolant (refrigerant, coolant) is designed to transfer heat from water blocks heated by system components to radiators that dissipate it into the atmosphere. Unlike ordinary water, specialized fluids are more efficient and do not lead to corrosion of the LSS components. Coolants can be different colors, including those with fluorescent additives.

Advantages of water cooling

The main advantages of SVO

- First of all, this is an incredible efficiency, expressed in the stability of the temperature regime. You will be comfortable playing or working without freezes and overheating.

- Overclocking capabilities without loss of stability of the system. You will be able to get additional performance due to higher and safer overclocking of the system.

- A significant reduction in noise levels, up to complete silence. This will help you get rid of the annoying noise.

- Reducing the level of dust that accumulates inside the computer - increasing the life of all components.

- Unique appearance and the design will make your computer look different from most standard, boring PCs.

I welcome everyone!

I was sorting through the rubble on the laptop and found pictures from 6 years ago, where I captured the process of creating a homemade water cooling system (SVO) computer.

Well, let's start in order. A lot of people are probably wondering: "Anafiga?"

I will answer right away.

Prehistory

The top model of the Intel Core 2 Quad 2.83GHz/12MB L2/1333MHz /LGA775 processor was purchased at one time for a tidy sum of money, which still pleases with its performance.

There is also a WD 1GB/32MB/Black/SATA2 screw, 4GB DDR2 800MHz (Up to 1300MGz) with a self-made heatsink, a top video card Saphire ATI HD6870, then a recently appeared top model with DX11 support.

I also purchased an ASUS R.O.G gaming motherboard. series X35-chip 2xPCIEx16 with the expectation of installing a second video card and assembling Crossfier or SLI. A little later, a second card was purchased, but not similar to Saphire ATI HD6870 and not even another model "Red Family", and it was decided to make friends of two irreconcilable rivals ATI and NVIDIA, purchased ASUS GeForce GT9600 solely to support proprietary technology "Green Camp"- PhysX.

For those who do not quite understand why this is, PhysX technology provides support for the physics of movement and interaction of small objects in game graphics as close to reality as possible, such as: dust in the rays of light, foliage in the wind, flying fragments, etc.

Here is a demonstration of the technology effect PhysX in the aquatic environment:

In the game I once loved Sacred 2

B Borderlands 2

In Batman: Arkham Origins

Well, and a lot of where else - you can find in tyrnet.

Why not install a video card then? "green camp"? - competitors from "red camp" with equal power, they are, as a rule, cheaper or have more power at equal prices. The only thing missing is such a trifle as physics) You can take a very cheap card for physics. The main requirement for it is the presence of a more or less productive GPU. The presence of a "wide" bus and fast and large memory is not needed! And these video cards cost quite a bit.

The monster Saphire ATI HD6870 with a reference cooling system took up a lot of space in the case, had a high-performance and, as a result, loud turbine, the frankly cheap ASUS GeForce GT9600 had a poor heatsink and a wretched cooler on it, as a result of which the high-performance GPU heated up to temperatures of about 87-96 degrees! Not in order!

To all this, I will also add a processor overclocked from standard 2.83GHz to 3.6GHz. The heat and noise was mooore. I assembled such a system with a margin for 5-6 years, while I was studying at the institute (a correspondence student, I paid from my own pocket, therefore I took it with a margin - there will be no money on the computer during my studies), so that it provides comfortable graphics all games with resolution up to FullHD and maximum graphics settings - I'm not used to compromise))

Overclocked iron, high-performance video system generated a lot of heat. And we don't get heat from anywhere. It is taken from the web! The power of one 450W PSU was insufficient and a second 350W PSU was installed, the load was distributed between them. Why not buy one new powerful PSU? - and you look at their prices ... market.yandex.ru/model.xm...odelid=6199502&hid=857707 At that time they cost around 5-7 thousand.

First put up with the noise, opened the balcony - the system unit was cooled by fresh frosty air, but with the onset of summer the situation became more complicated. The computer simply began to overheat!

Something had to be done. He began to dig the Internet in search of ways to remove heat. In the meantime, I equipped the system unit with additional coolers for maximum heat removal from the box.

At that time, 12 (!) coolers miraculously coexisted in the system unit! Among which, 2 are power supplies, 1 is a processor, 1 is a cooling system for the processor power supply, 2 are video cards and 6 pieces provided ventilation for the box.

Is it necessary to talk about what a howl was from this monster!

Having studied the Internet, the path of the samurai was chosen; the most affordable type of high-performance cooling for the home is NWO. Buying something like this in Ekb is a problem, I'm not talking about our outback. Yes, and such systems cost oh, how not cheap. Well, in the end! Our hands are not for boredom!

Thus, the decision was made to independent creation water cooling systems for home computer.

I immediately apologize for the terrible quality of the photo - then there was only a phone and the phone was ancient)

This is what the system unit looked like before the upgrade. At first there was only one video card.

There is no place for a second PSU ((

In the first version, one waterblock was installed per CPU. The whole system was a hermetic system of transparent hoses, a redesigned aquarium pump, a processor water block, a cooling radiator with two 120mm fans powered by 5V to minimize noise, an expansion tank with a pressure and flow circulation sensor, and circuits for protecting against leaks and stopping coolant circulation .

CPU waterblock

Was made from scratch. The base - the heat sink is cut out of a thick piece of electrical copper (~4mm thick). I cut out 120 plates of the heat exchange chamber from thin sheet copper (0.4 mm), laid them with electric cardboard, pulled them together, tinned one plane and soldered them to the base. After removing the electric cardboard, we got a base with a heat sink from 120 plates.

CPU waterblock

The shirt was made from a piece of thick plastic that fell under the arm. The top is a 1mm copper plate with copper fittings soldered to it.

From above, we install an X-shaped iron plate 1mm with holes for mounting studs instead of the standard radiator fastening latches and tighten the entire "sandwich" on the sealant with four screws.

coolant radiator

Was made from Gazelle stove copper radiator. But as it is, it was too bulky, and I set himself the goal of fitting the entire CBO into the case of the system unit so that nothing sticks out. The system unit is a regular MidiTower.

Therefore, we arm ourselves with a hacksaw for metal and ruthlessly cut the radiator to the size of the system unit!

While the radiator is open, we change the fitting to a smaller diameter so that our tube is put on. Also, do not forget to put a waterproof partition in the middle between the fittings, so that the coolant passes through the radiator, and not stupidly from fitting to fitting. We cut out and solder the missing walls from sheet copper.

Now an important point. The radiator fins are already very often located and it will be unrealistic to blow through them with computer coolers, and even at a reduced power supply. Therefore, we arm ourselves with a screwdriver, scissors and extremely carefully we squeeze the radiator plates together, increasing the clearance.

There is a difference!

Be sure to check for tightness. From the first time it is almost impossible to assemble hermetically. Therefore, we are looking for holes and how to solder. If the place is not available, then it is permissible to shed with sealant. It should be checked for tightness after the plates have been moved apart. there is a very high probability of damaging the radiator channels (I pierced it in 2 places).

Pump completion

A couple of pumps were purchased (~$10 apiece). if the pump fails, the computer will be unusable.

The essence of the revision is to reduce the noise of the impeller and install new fittings.

The impeller has some travel relative to the rotor magnet to reduce water hammer. But this creates unnecessary noise, because the impeller was tightly glued to the magnet on silicone. Also, 2 washers of millimeter thickness are made of silicone on the ends of the axle to mitigate longitudinal impacts.

New fittings were glued on epoxy.

Finished pump

It should be added that in order to reduce the transmission of vibrations from the pump to the body of the system unit, the pump was installed on a spring suspension on a piece of plexiglass, and it, in turn, is also on springs to the hardware of the system unit. There is no photo of this unit, sorry.

Expansion tank

Made from a suitable plastic container. You can even from a glass jar, even from a piece of a sewer pipe with muffled ends - there is someone who is good for that. Mine was flat and wide in order to fit at the bottom of the system unit and not interfere with the installed PCI bus cards.

We install 2 fittings, make a partition, leaving a small gap - this is for better separation of air bubbles from the water.

A miniature computer three-wire cooler was chosen as the flow sensor. The photo is not in a good position. It should be placed with the blades directly in front of the fittings so that it starts to rotate.

The signal from the Hall sensor is taken by the yellow wire and goes to the coolant circulation control board.

As leakage protection the option of creating a slightly reduced pressure in the system was chosen - so that the soft tubes of the system would not be crushed, but at the same time, if a leak occurs, not liquid will flow out of the system, but air will enter the system.

Pressure meter was created from latex, mounted on the cap of the expansion tank.

In the cover we cut a hole 10 mm smaller than the diameter of the latex membrane, glue the membrane on top, glue a small contact pad with the wiring soldered to it. We install a U-shaped structure on top, screw in the adjusting screw and connect the wires to it (I have 2 legs made of plexiglass, a piece of textolite with a soldered nut and a bolt in the nut). We adjust it so that at normal atmospheric pressure, the membrane rising closes the contact and the screw.

Membrane with contact

Finished sensor

Because I still had ATI under warranty, so I didn't disassemble the expensive card and install a water block on it. Later, the waterblock was assembled and installed on an "auxiliary" video card, thereby significantly lowering the decibels.

Video card water block was created using a technology different from the water block of the processor.

Several spirals of copper wire were soldered onto a copper base, thereby forming cooling fins. A copper casing is curved and soldered on top. The heating intensity of the video chip is several times less, so such a simplified water block is quite the place to be.

Video card water block with fasteners.

Oh yes system protection!

I created it on a small scarf, which I placed on the cover of the top free CD-ROM slot. The circuit had an indication of the modes on the LEDs, a button to force the pump to start even when the computer was turned off - this was to facilitate the process of filling the system with water, and a relay output to turn off the computer's power in the event of a leak or stop the circulation of the coolant and a relay to turn on the pump. Starting the computer remained regular. When the PSU is turned on, voltage is applied to the pump enable relay and the entire system starts to function.

One NO. Because power supplies in the event of a leak were completely de-energized, it was not possible to power the circuit from the 5V duty room and had to be supplied third already a power supply, but low-power based on a conventional transformer)) Now it would be possible to put a charger from a mobile phone in its place.

Tests spent in the laboratory on the table.

Broach, purge ...)

Assembly and start

First of all, I cut out a place for the second PSU from below under the HDD, provided ventilation holes for blowing out warm air.

I installed a massive radiator with two 120mm coolers installed on it at the very top, occupying 2 lots for a CD-ROM. Naturally, we cut out the top of the system unit for the removal of heated air. What's plus is that my system unit has a decorative cover with ventilation holes on top, so the radiator is not visible from the outside!

We put a protection board with an indication and a button for forced start of the pump on the top plug of the radiator compartment. 2 DVD-ROMs go down.

We fix 3 relays on the wall under the main PSU (2 for power off and 1 for starting the pump) - ordinary 12V automotive ones, but with a slightly modified design, so as not to let 220 into the computer's power circuit. The pump itself will also be located there.

We arrange everything as it should be and put the video card. We connect the third PSU, which I installed on the side cover of the system unit on the connector.

The system is assembled and running. Everything worked right away. And above all, I was struck SILENCE ! After that infernal roar that the system unit was emitting before, there was only a barely audible rustling of power supplies and a pump. Well, the video card made itself felt only in powerful games))

Total what we have.

Was:

CPU 2.83GHz/1333MHz t=80degrees

RAM 800MHz

GPU NVidia 915MHz t=94degrees

HDD t=53 degrees

Wild roar of coolers

It became:

CPU 3.6GHz/1900MHz t=54degrees

RAM 1300MHz

GPU NVidia 1050MHz t=62degrees

HDD t=43 degrees

And the silence...

Asking price:

Pumps 2pcs 20$

Gazelle stove radiator copper 30$

Tubes transparent 2$

Distilled water 1$

Clamps 5$

Orgsetclo, hardware, springs, copper, tools - free of charge.

Experience and job satisfaction are priceless!

The goal has been reached. He had a powerful overclocked computer with low noise and stable operation, the entire system fit inside the system unit. But everything is crowded there ... And he began to weigh a ton, not otherwise!)))

But this barrel of honey was not without a drop of tar...

Over time, leaks began to appear, and there was no time and desire to search and eliminate. Because the protection board was disabled, for which he paid after a while. At one point, the computer greeted me with a cold black screen after pressing the power button. From the water block of the processor, water ran into the video card, killing it. Fortunately, there was a second video card, on which it lasted until buying a new one. The motherboard also got a little, which is why its life has decreased significantly. Now stands and new mother, and a video card with a capacity similar to the deceased, but already 2 times cheaper. The processor is the same, DDR3 4GB RAM, the hard one is the same.

Good cooling of the central processor and video card processor for the last decades has been a necessary condition for their uninterrupted operation. But not only the processor and video card are heated in the computer - a separate cooler may be required for the chipset chip, hard drives and even memory modules. Case manufacturers add additional fans, increase their power and dimensions, and improve the design of radiators. And, of course, liquid cooling systems could not be ignored.

In general, liquid cooling of processors is not a new topic: overclockers have been faced with insufficient air cooling efficiency for a long time. "Overclocked" to the theoretical maximum, the processors heated up so that none of the coolers available for sale at that time could cope. There were no liquid cooling systems in stores, and overclocker forums were filled with topics about homemade "dropsy". And today, many resources offer to assemble a liquid cooling system on their own, but this makes little sense. The cost of components is comparable to the price of inexpensive LSS in stores, and the quality (and, therefore, reliability) of a factory assembly is usually still higher than a handicraft one.

Why is the LSS efficiency higher than that of a simple cooler?

The considered LSS do not have cold-producing elements, cooling occurs due to the air near the system unit - as in the case of conventional air cooling. The efficiency of LSS is achieved due to the fact that the rate of heat removal using a moving coolant is much higher than the rate of natural heat removal using heat transfer inside a metal radiator. But the rate of heat removal depends not only on the speed of the coolant, but also on the efficiency of cooling this liquid and on the efficiency of its heating by the heat of the processor. And, if the first task is solved by increasing the area of the radiator, the area of the heat exchanger of the radiator and improving the airflow, then in the second case, heat transfer is limited by the area of the processor. Therefore, the overall efficiency of the system is limited by the efficiency of the processor's water block. But even with such a limitation, LSS provide about 3 times better heat removal compared to conventional air cooling. In numbers, this means a reduction in chip temperature by 15-25 degrees compared to air cooling at normal room temperature.

LSS design

Any liquid cooling system contains the following elements:

- water block. Its purpose is to effectively remove heat from the processor and transfer it to flowing water. Accordingly, the higher the thermal conductivity of the material from which the sole and the water block heat exchanger are made, the higher the efficiency of this element. But heat transfer also depends on the area of contact between the coolant and the radiator - therefore, the design of the water block is no less important than the material.

Therefore, a flat-bottomed (channelless) water block, in which liquid simply flows along the wall adjacent to the processor, is much less efficient than water blocks with a complex bottom structure or heat exchangers (tubular or serpentine). The disadvantages of water blocks with a complex structure is that they create much more resistance to water flow and, therefore, require a more powerful pump.

- water pump. The widespread opinion that the more powerful the pump, the better, and that LSS without a separate powerful pump is generally ineffective is incorrect. The function of the pump is to circulate the coolant at such a speed that the temperature difference between the water block heat exchanger and the liquid is maximum. That is, on the one hand, the heated liquid must be removed from the water block in time, on the other hand, it must enter the water block already completely cooled. Therefore, the power of the pump must be balanced with the efficiency of the other elements of the system and replacing the pump with a more powerful one in most cases will not give a positive effect. Low-power pumps are often combined in one housing with a water block.

- Radiator. The purpose of the radiator is to dissipate the heat brought by the coolant. Accordingly, it should be made of a material with high thermal conductivity, have a large area and be equipped with a powerful fan (fans). If the LSS heatsink area is comparable to the CPU cooler heatsink area and the fan installed on it is no more powerful, then you should not expect such an LSS to be more efficient than the same cooler.

- The connecting pipes must be of sufficient thickness so as not to create a large resistance to the water flow. For this reason, pipes with a diameter of 6 to 13 mm are commonly used, depending on the fluid flow rate. The tubing material is usually PVC or silicone.

- The coolant must have a high heat capacity and high thermal conductivity. Of the available and safe liquids, ordinary distilled water satisfies these conditions best. Often additives are added to water to reduce its corrosive properties, to prevent the growth of microorganisms (blooming) and simply for aesthetic effect (color additives in systems with transparent tubes).

In powerful systems with a large volume of coolant, it becomes necessary to use an expansion tank - a reservoir into which excess liquid will go during its thermal expansion. In such systems, the pump is usually combined with an expansion tank.

Characteristics of liquid cooling systems.

Serviced / unattended LSS.

Maintenance free system comes from the factory completely assembled, filled with coolant and sealed. Installation of such a system is simple - some maintenance-free coolers are no more difficult to install than a regular cooler. The unattended LSS also has disadvantages:

- Low maintainability. The tubes are often simply soldered into one-piece plastic fittings. On the one hand, this ensures tightness, on the other hand, replacing a damaged element of such a system can cause complications.

- The complexity of replacing the coolant is usually also associated with the repair of the system - if part of the liquid has leaked out, it can be very difficult to refill the unattended LSS - such systems, as a rule, are not supplied with filling holes.

- Low versatility is associated with the non-separability of the system. It is impossible to expand the system or replace any of its elements with a more efficient one.

- The fixed length of the tubes limits the possibilities for choosing the location of the radiator.

Served LSS are often supplied as a set of elements and the installation of such a system will take time and some skill. On the other hand, the possibilities for customizing it are much higher - you can add water blocks for the chipset and for the video card, change all the elements to more suitable ones for a particular computer, move the heatsink to any (reasonable) distance from the processor, etc. You can not be afraid of the socket (and cooling system) becoming obsolete when replacing the motherboard - to restore relevance, you only need to replace the processor water block. The disadvantages of serviced LSS, in addition to the complexity of installation and high price, include a high probability of leakage through detachable connections and a high probability of contamination of the coolant.

LSS must support socket motherboard on which it is installed. And if a serviced LSS can still be adapted to another socket by purchasing an additional appropriate water block, then an unattended LSS can only be used with those sockets that are listed in its characteristics.

Number of fans does not directly affect the efficiency of LSS, but a large number of them allows to reduce the rotation speed of each individual fan while maintaining the total air flow, and, accordingly, reduce noise while maintaining efficiency. Whether a CBO with a large number of fans will be more efficient depends on their total maximum air flow.

Max airflow calculated in cubic feet per minute (CFM) and determines how much air is forced through the fan per minute. The higher this value, the higher the contribution of this fan to the efficiency of the heatsink. Dimensions ( length, width, thickness) radiators are no less important - four powerful fans blowing a simple thin radiator with a small plate area will cool the coolant no better than one fan well matched to a radiator with a large area of \u200b\u200bplates.

Radiator material determines its thermal conductivity, i.e., with what speed the heat transferred to it will be distributed over the entire area of \u200b\u200bthe radiator. The thermal conductivity of copper is almost twice as high as the thermal conductivity of aluminum, but in this case, the efficiency of the radiator depends more on its design and area than on the material.

Water block material, due to its limited size, is more important than the material of the radiator. In fact, copper is the only viable option. Aluminum water blocks (found in cheap LSSs) reduce system efficiency so much that it makes no sense to use liquid cooling.

Maximum noise level depends on maximum fan speed. If the system does not provide speed control, this parameter should be paid close attention. If there is a speed control, attention should be paid to minimum noise level.

Noise levels above 40 dB can already be perceived as uncomfortable (40 dB corresponds to the usual sound background in a residential area - soft music, calm conversation). To ensure that the noise of the fans does not interfere with sleep, it should not exceed 30 dB.

Rotation speed adjustment fans can be manual and automatic. Manual adjustment allows you to change the fan speed according to personal preferences, while automatic adjusts the speed to the current temperature of the processor and provides Better conditions equipment operation.

Power connector type can be 3-pin and 4-pin.

3-pin The connector does not have a separate wire for changing the fan speed. You can control the rotation speed of such a fan only by changing its supply voltage. Not all motherboards support this method. If your motherboard cannot control the rotation speed of a 3-pin fan, then the coolers and pump motor with a 3-pin power connector will always rotate on top speed. To change the degree of cooling, you will have to buy additionally