Technical characteristics of the ZF gearbox. Gearbox ZF - German quality, now also in Russia

Features of the gearbox for KamAZ 5320

KAMAZ vehicles with engines 740 51-320 or 740.50-360 are equipped with a gearbox model 161 or ZF-16S151 of the German manufacturer "ZAHNRADFABRIK", and KAMAZ with an engine 740 14-300 is equipped with a gearbox model ZF-9S109 of the German company "ZAHNRADFABRIK" .

The main characteristics of the KamAZ gearbox (model 161): mechanical, 8 steps, consists of a main 4-speed gearbox and a planetary demultiplier, which is located behind the main box.

Gear ratios:

|

Gearbox type |

|||||||||||

Legend:

L - slowdown gear in the divider;

S - accelerating transmission in the divider;

R - reverse;

C - low gear.

The shift lever support is located on the gearbox cover and includes:

gear control lever

· system of protection against casual inclusion of a reverse;

· valves of management of a demultiplier on pneumatics.

The main characteristics of the gearbox for KAMAZ (model ZF-9S109): mechanical, 9 steps, has an additional downshift, which the model 161 does not have.

The main characteristics of the gearbox for KAMAZ (model ZF-16S151): mechanical, 16 steps, consists of a main 4-speed KamAZ box with a built-in 2-stage divider, which is located in front of the main box, as well as a 2-stage planetary demultiplier located behind the main box.

How to adjust the gearshift control remote actuator for ZF-16S151 and 161 models? Follow the instructions and also see fig. 1.

Lock the gearshift lever in the neutral position;

· with the help of a technological rod 4 (d=4mm, l=100mm) fix the rod 4 in the support 2;

· put the shank 9 into the hole of the lever 5, while the nut 10 is tightened to a torque of 40...50 Nm and splinted;

remove the technological rod;

Deviate from the vertical the common plane of symmetry of the lever 1 and the rod 3 by 2 mm maximum by changing the length of the rod 7.

Rice. 1 ZF-9S109 gearshift control actuator

Features of the gearbox for KAMAZ ZF-9S109

How to work with gearbox for KAMAZ ZF-9S109:

· the gearshift lever is installed at an angle E to the vertical;

Then the lever is set at an angle W to the vertical;

· the conical axis is aligned with the axis of the hole by rotating the shank in the lever;

· the general plane of symmetry of the lever deviates by 2 mm maximum from the vertical plane;

slotted nuts are tightened and cottered;

· the nut is tightened.

To determine the oil level in the gearbox housing (model 161), use the dipstick in the plug oil filler neck. If the oil level is in order, it reaches the upper mark on the pointer. Please note that when checking the level, the plug is inserted into the hole to the level of the thread.

For KamAZ gearboxes of the ZF-16S151 and ZF-9S109 models, the optimum oil level should be at the lower edge of the filler hole.

How to change the oil in the KamAZ gearbox crankcase?

The oil must be drained while warm from the operating heat. When working with model 161, it is necessary to unscrew the oil filter 1, which is located on the rear end of the crankcase of the range converter, crankcase plugs 2 and 3 are also turned out (see Fig. 2) When working with models ZF-9S109 and ZF-16S151, drain and filler plugs are holes. Magnetic plugs are cleaned of dirt after draining the oil, after which they are installed in place.

How to eliminate possible malfunctions of a KamAZ car?

If the inclusion of gears in the box is difficult, then this may be due to incomplete engagement of the clutch. In this case, it is necessary to adjust the clutch actuator.

Cases when gearboxes do not turn on or spontaneously turn off on the go, indicate that the adjustment of the remote drive is broken, or the fastening of the levers of the drive rods is out of order. To correct the problem, it is necessary to tidy up the drive or tighten the mounting of the levers.

Request a free call

Request a call

KAMAZ vehicles

MAZ vehicles

KRAZ vehicles

URAL cars

- __________________

Maintenance of ZF checkpoint for 16 Kamaz-6520 vehicles

The sixteen-speed gearbox ZF 16s151 KAMAZ is installed on the chassis, dump trucks, KAMAZ-6350, 6450, 6520, 65221, 65225, 5460 heavy family vehicles.

The ZF-16 gearbox consists of the following main components: the main four-stage gearbox, the front two-stage gear divider and the demultiplier.

All forward gears in the main gearbox are switched on by synchronizers, reverse gear - by a gear clutch. The highest gear is overdrive.

Gearbox range ZF 16s151 is planetary, automatically switches using a pneumatic valve with a synchronizer when the lever is moved in neutral from the position of 3-4 gears to 5-6 and vice versa.

Gearbox divider ZF-16 KAMAZ-6520 - mechanical, consists of two pairs of cylindrical gears and a synchronizer. Pneumatic divider control. The weight of the gearbox is 290 kg. Maximum torque 1850 N/m.

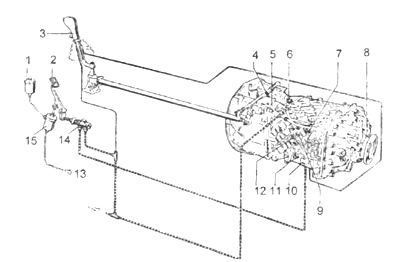

Rice. 1. Scheme for connecting the pneumatic control of the ZF 16 KAMAZ-6520 gearbox for the divider and demultiplier

1 - clutch reservoir; 2 - clutch pedal; 3 - gear lever; 4 - reverse sensor; 5 - valve for switching on the demultiplier; b - neutral sensor; 7 - sensor for switching on the lower range of the demultiplier; 8 - cylinder for switching the demultiplier; 9 - first gear sensor; 10 - air distributor of the divider; 11 - sensor for switching on the lower range of the divider; 12 - high gear engagement sensor; 13 - to the clutch slave cylinder; 14 - valve for switching on the divider; 15 - clutch master cylinder.

The ZF-16s151 gearbox consists of the following main components: the main four-stage gearbox, the front two-stage gear divider and the demultiplier. All forward gears in the main gearbox are switched on by synchronizers, reverse gear - by a gear clutch.

Gearbox range ZF 16 KAMAZ-6520 - planetary, automatically switches using a pneumatic valve with a clutch synchronizer when the lever is moved in neutral from the position of 3-4 gears to 5-6 and vice versa.

Gearbox divider ZF-16 KAMAZ - mechanical, consists of one pair of cylindrical gears and a synchronizer. Pneumatic divider control.

The gears of the ZF 16s151 gearbox are engaged mechanically, through double engagement. It is divided into 5 adjacent tracks. On tracks 3-4 or 5-6 is the neutral position of the lever.

The spring clamps of the ZF 16 KAMAZ-6520 gearbox constantly press the lever to the neutral position. Pneumatic switching of the demultiplier occurs automatically when the lever is moved in neutral from the position of 3-4 gears to 5-6 and vice versa.

The preliminary gear selection in the divider is made by moving the pneumatic valve switch installed in the gear lever handle in one of the positions.

The transmission in the gearbox divider ZF 16 Kamaz switches after pressing the clutch pedal. Depending on the conditions of use of the vehicle, you can use a divider in any gear.

The ZF 16 KAMAZ gearbox servo amplifier consists of a control unit and a two-position cylinder. The inclusion of gears in the gearbox is carried out as described above, only with pneumatic amplification. Benefit: Reduced shift effort.

Long-term engagement of gears with high manual force contributes to increased wear of synchronizers.

Gearbox KAMAZ KPP ZF-16, depending on the model of the car, can be equipped with a power take-off.

Problems when changing the positions of the range selector (for example, tracks from 3-4 gears to 5-6 gears or vice versa) may have the following causes:

Damage to the pneumatic system.

Switching valve or switch cylinder with defects (condensate or contamination).

Continuation of the movement is possible only when the lower range of the demultiplier is on (1-4 gears).

If the direct range transmission remains engaged, the vehicle can be towed.

Operation of a Kamaz vehicle with a ZF gearbox at low temperatures.

Gearbox ZF-16 KAMAZ is filled with oil according to the chemotological map. The gearbox can operate at ambient temperatures down to -30°C. The following points must be taken into account:

At external temperatures up to -20°C - after starting the engine, a period is required to warm up the gearbox. Warming up transmission oil must be carried out with partial (partial) load at low speed.

At external temperatures up to -30°C - before starting the engine, it is necessary to warm up the gearbox with warm air. It is also necessary to pay attention to the fact that the temperature in the gearbox should not exceed 150°C.

To guarantee the long life and performance of the synchronizers, the clutch must function flawlessly.

Clutch function must be checked as follows:

On idling depress the clutch of the engine;

No more than 20 sec. slowly engage reverse gear).

If a “grinding” of gear couplings is noticed, then it is necessary to adjust the clutch or check it.

Before the gearbox divider ZF-16 Kamaz is switched on through the shut-off valve, the clutch must be fully open.

In case of incorrect installation of the shut-off valve, there is a risk of destruction of the synchronizer when shifting gears of the divider.

Checking the clutch of a Kamaz car for the ZF-16 gearbox

Adjust clutch

Install the adjusting screw on the clutch pedal so that the valve opens and closes in the area.

In position, the clutch is fully open. In this position of the pedal, the gap between the valve and the stop screw must be at least 1 mm.

Maintenance of the pneumatic installation of the gearbox ZF 16

Condensation occurs in every pneumatic installation. To prevent condensate and rust from getting into the valves and pneumatic cylinders from the receiver, regular inspection of the pneumatic system is necessary. The receiver must be dehydrated weekly and daily in winter.

Together with the receivers, moisture must also be removed from the filters using a water separator, if it does not work automatically.

Gearbox ZF 16

Gearbox designation - ZF 16s151

Specification number - 1341.002.073/1341.002.074

Flange - end slots 1297.333.110

Cover of the rear bearing of the input shaft, clutch housing, lever and fork (if not serial) - 1315.302.136 cover, 1315.368.025 fork, 1316.301.064 crankcase

Gearbox input shaft (splines) and output shaft - 1315.302.153 SAE10C 2"" 1315.304.131

Cover of the back bearing of a secondary shaft assy and detail - 1315.231.004, 1315.301.220

Note - standard version.

The universal 16-speed gearbox ZF 16S151 is highly reliable and easy to use. In our country, they are often installed on KAMAZ vehicles instead of factory boxes. In turn, they can be equipped with trucks belonging to the heavy class Man, Daf, Iveco and Renault.

Depending on the purpose of the ZF 16S151 gearbox, there may be modifications that differ slightly in design.

Device diagram

The design of the gearbox consists of the following units:

- main 4-stage gearbox,

- front 2-speed gear divider,

- demultiplier.

The forward speeds in the main gearbox are switched on with the help of synchronizers, the rear speed is switched on by a gear clutch. The demultiplier has a planetary design, switching occurs automatically using a pneumatic valve. The weight of the ZF 16S151 gearbox is 290 kilograms. Limiting torque - 1850 Nm.

The speed divider has a mechanical design, it includes a pair of cylindrical gears and a synchronizer.

The gears are engaged mechanically, by means of a double H-shift, which is divided into five adjacent ones.

The lever is pressed to the neutral position with the help of spring clips. Pneumoswitching of the demultiplier occurs in automatic mode while moving the lever in neutral.

The choice of speed in the divider occurs due to the movement of the pneumatic valve switch, which is located in the shift lever handle to position B or H. Switching occurs after depressing the clutch pedal. Depending on the conditions of use of the car, you can use a divider at any speed.

The servo amplifier includes a control unit and a 2-position cylinder. The inclusion of speed in the ZF 16S151 gearbox is carried out as a result of pneumatic amplification.

The main advantage of this type of transmission is the reduction in gear shifting effort.

Many drivers who use such transmissions note not only significant fuel savings, but also unpretentious maintenance. It also saves a lot of fuel.

Reviews

The need for 16-speed gearboxes arose from KAMAZ in the early 2000s, when the plant mastered the production of heavy trucks with a gross weight of 33-41 tons or as part of a road train - 44 tons. The smaller the range of gear ratios of the box is broken, the less the engine strains, the road train accelerates faster and easier, it is easier to overcome climbs, the engine can be kept in an economical rev range. At that time, Chelny residents began to buy boxes from ZF, but in very small batches. The series of victories of the KAMAZ-Master team at the Dakar super marathons, which have become an ordinary event for the Chelny team since the early 2000s, made the Germans finally believe in the potential of a new client. Sports cars are assembled at a separate production facility, with a diesel engine of the YaMZ-840 series (according to various estimates, from 850 to 1050 hp), with which it is the 16-speed ZF 16S251 gearbox, designed for a torque of 2500 N.m., that is aggregated. In January 2005, as soon as another victorious Dakar for KAMAZ ended, it was decided to create a joint venture. But these boxes are used in races and DAF, MAN, IVECO, Renault - ZF specialists are proud to tell carriers about this.

Well-established technology

From the very foundation, from the end of 2005, the production of TsF KAMA LLC was located on a territory leased from KAMAZ with an area of about 5 thousand square meters. meters. The new, own production building has almost five times larger areas: 22.1 thousand m2, of which 18.5 thousand m2 are directly production areas and logistics zones. Such space will be appreciated not only by the old employees of the joint venture - they employ about 350 people, but also by new ones who are planned to be hired taking into account the increase in production volumes. And this (by December 2014) is about 150 more people. Additional "squares" will not be empty - new equipment is placed on the squares, contributing to the expansion of the range of gearbox parts produced in Russia, and, importantly, thermal production. Previously, heat treatment of parts was done at the corresponding production facility of KAMAZ. The fact is that case-hardened steels, naturally approved by the Germans, are used as the material for gears of ZF boxes. Such steel is cheaper than alloy steel, but requires very careful adherence to carburizing technologies. Recall that the process of carburizing a steel part is the saturation of its surface layer with carbon. This gives the surface a high hardness, but leaves a tough, impact-resistant core. An example of cementation, which is heard by motorists, is a piston pin.

The opening of the new building once again confirms that in Chelny, from the very beginning of the work, the joint venture sought to organize not a screwdriver assembly of boxes from kits brought in "bags", but a full-fledged production, for the development of the entire range of parts. Among ZF Friedrichshafen AG's worldwide production sites, there are only two factories with a mixed conveyor that allows the production of two types of gearboxes - the 9-speed ZF Ecomid gearbox and the 16-speed ZF Ecosplit gearbox. One of them is at the head plant in Germany, in Friedrichshafen, the other is at the ZF KAMA joint venture. Moreover, the assembly line is readjusted from the production of one type of boxes to another in almost a minute. The boxes are assembled on a looped conveyor, where the sub-assembled nodes arrive along the radii from the outside. Boxes of the Ecosplit and Ecomid families are very different, it is difficult to confuse something, but all the same, the assembly is divided into cycles, which include six sets of one or another box. Technological equipment for assembling each type of box has its own and is painted in its own color: yellow or blue. Very important point when assembling ZF boxes - selection of the thickness of the locking and adjusting rings. The preload of the tapered bearings depends on this. Overtightened or weakened - the result will be the same: a decrease in the resource of the unit. Another feature is that locking sealant Loctite 241 is widely used in threaded connections.

All assembled boxes must go to the test stand. Here the break-in mode is as follows: 10 minutes and no load. The ease of gear shifting, the absence of extraneous noise, the oil pressure created in the lubrication system, and the tightness of the pneumatic circuits are controlled. If assembly flaws are identified, the box is sent to a special area, where it is dismantled and the cause of the malfunction is looked for. But such cases are literally counted ...

Now the boxes of the Ecomid and Ecosplit families, in addition to KAMAZ, are purchased not only by the Ural automobile plant, but also by the St. Petersburg plant MAN. This speaks of high quality Chelny boxes. In addition, there were cases when parts manufactured here were sent from Naberezhnye Chelny to Europe, to other ZF factories.

Important task

Both the Germans and KAMAZ itself are interested in localizing the production of box parts. According to JV specialists, localization allows:

reduce the delivery time of parts to the conveyor and their stocks;

reduce the cost of developing a network of suppliers;

meet the legal requirements of the host country;

minimize currency risks and risks associated with customs clearance of parts supplied from abroad.

Potential Russian suppliers to the conveyor "ZF KAMA" were waiting for a serious audit of production, then work with drawings, production of trial parts. The decision to cooperate with a potential supplier was made based on the results of a quality analysis, taking into account the price of parts. As a result, KAMAZ OJSC, ChKPZ OJSC, ZMZ OJSC, RosALit LLC, OEMK OJSC became the Russian partners of the JV in machining, forging and foundry production. In 2008, localization began with the production of three shafts and seven gears for Ecosplit boxes. The production of blanks for gears and shafts, their mechanical and heat treatment, as well as the machining of three variants of Ecosplit gearbox housings was carried out at the engine plant of KAMAZ OJSC. The necessary rolled steel is supplied to the forging plant of OJSC KAMAZ by OJSC OEMK. Eight out of eleven types of gears for boxes of the Ecomid family are made at the ZF KAMA JV. Another nine gears are made for the joint venture by KAMAZ itself. In 2010, blanks of seven gears of Ecomid boxes were localized at ChKPZ OJSC, machining of eight gears and three shafts of the Ecomid gearbox is carried out at the TsF KAMA production site, and their heat treatment is carried out at KAMAZ OJSC. The design feature of ZF boxes is the cases cast from aluminum alloy. - At first, no one undertook to make hull castings in Russia - they were supplied from Germany. There was an attempt to master the casting of a relatively simple clutch housing at the Zavolzhsky Motor Plant, but it ended in failure. And this is with 40 years of experience in the Trans-Volga region with aluminum alloys! In 2011, a project was launched to localize blanks for seven aluminum crankcases. The first samples of Ecomid clutch housing castings were made at the KAMAZ Metallurgy foundry. Then the castings of six variants of the crankcases were localized at RosALit LLC in Nizhny Novgorod, two of them are processed at ZMZ, and the remaining four at the KAMAZ engine plant. In 2012, the casting and machining of the clutch housing at KAMAZ was localized, and the localization of three gears began. - The blanks of three shafts of Ecomid boxes and one Ecosplit gear were localized at the forging plant of KAMAZ OJSC, and three more gear blanks - at ChKPZ OJSC. The production of two types of cast-iron covers for the input shaft was mastered at the KAMAZ engine plant. Thus, as of April 1, 2014, the level of localization of parts for Ecomid and Ecosplit boxes at ZF KAMA JV is 52 percent, but bearings, synchronizers, and seals are supplied from Germany. From latest news: for Chelny ZF boxes at another joint venture - at Knorr-Bremse KAMA LLC, they mastered the CCGT clutch. The Germans believe that the Russian partners of ZF KAMA will eventually grow to the level of global suppliers of the concern, meeting all the requirements of ZF in terms of quality, technology and price, up to the supply of parts from Russia to other enterprises of the company.

Information

- ZF Friedrichshafen AG is the world's largest manufacturer of transmission, steering and suspension components for vehicles. ZF products are used by almost all European automotive companies. The company produces a whole range of gearboxes for trucks and buses: the simplest, for 5-6 gears, for delivery medium-duty vehicles, for heavier vehicles, 8-9-speed gearboxes with a planetary demultiplier are used, and the most structurally complex gearboxes are made with two additional gearboxes: with front step-up - divider and step-down planetary - demultiplier. Here, if the main gearbox is three-stage, then taking into account these two gearboxes, in total, 12 gears are obtained, and if the main gearbox has four stages, then there are 16 speeds in the unit. ZF has these gearboxes, one might say, flagship ones. Mercedes, Scania, Volvo have similar boxes, but KAMAZ and YaMZ never had them. Everything was limited only by development. Recall that the Yaroslavl plant traditionally makes gearboxes for MAZ and URALAZ. The main advantage of 16-speed gearboxes is compactness and a wide range of gear ratios: usually from 16.41 to 1.00 or from 13.80 to 0.84. For example, the "KAMAZ" 10-speed gearbox model "154" is probably one of the best domestic gearboxes, but it provides a range from 7.82 to 0.81. To get traction capabilities comparable to ZF boxes with it, you would have to increase the gear ratio main gear. And this always worsens the economy. Practically in terms of gear ratios and ease of use, the only alternative to a mechanical 16-speed gearbox is a 5-6-band “automatic” with a classic GMF.

- Shareholders of ZF KAMA LLC: ZF Friedrichshafen AG, Germany - 51%, OAO KAMAZ, Russia - 49%;

JV LLC "CF KAMA" was founded in January 2005, and the assembly line was launched in November of the same year.

The company produces 9-speed gearboxes ZF Ecomid 9S1310 TO and 16-speed gearboxes ZF Ecosplit 16S1820 TO, which are aggregated with engines ranging from 160 to 500 hp. With. The main consumer of the JV products is OJSC KAMAZ, in 2012 the production of transmissions for OJSC AZ URAL and the St. Petersburg plant MAN started. In 2016, it is planned to start production of gearboxes for MAZ OJSC. At present, the production volume is about 20 thousand boxes per year, with the commissioning of the production facilities of the new building, up to 50 thousand boxes per year will be produced. - 2003 First negotiations between ZF Friedrichshafen AG and OJSC KAMAZ on the establishment of a joint venture for the production of gearboxes;

April 2005 Registration of JV "CF KAMA";

November 2005 Official opening of the enterprise, start of assembly of 16-speed transmissions of the ZF Ecosplit family;

2007 Expansion of the range of manufactured products, localization of parts for boxes, obtaining the status of "industrial assembly" and inclusion in the list investment projects Republic of Tatarstan;

2008 Launch of assembly of 9-speed gearbox ZF Ecomid;

2010 Start of production of localized gears and shafts for gearboxes of the ZF Ecomid family, certification of production according to ISO 9001 & TS 16949;

2011 Start of construction of a new production building;

2012 Successful completion of DQS and IQNet recertification audits;

2012 Assignment by the Federal Customs Service of Russia of the status of an authorized economic operator of foreign economic activity;

2013 Start of production at the joint venture of the output shaft for the ZF Ecosplit gearbox;

2014 Official opening of the new production building. Mastering the production of "ZF KAMA" in new areas, launching its own thermal site for hardening gears and heat treating shafts - ZF Ecosplit boxes have three gear ratio options, which are indicated on the plate: from 16.41 to 1.00; from 15.57 to 1.00; and from 13.8 to 0.84. Two options with a direct top gear and one with an overdrive, and these options are created only by the gears of the divider, the rest of the details of the boxes are the same. Usually, with an increase in the torque passing through the box, the gearing module increases - the tooth becomes slightly longer and at the same time thicker at the base. This leads to the need to increase the center-to-center distance between the shafts of the box, to make different cases. The Germans from ZF made it more cunning: with an increase in torque, they increase the length of the gears, that is, the length of the teeth in engagement - you also have to increase the length of the body. The 16-speed ZF Ecosplit gearboxes have three crankcase lengths: 932, 1015 mm and the longest crankcase 1031 millimeters - for the 16S2720 box, designed for a torque of 2700 N.m. Moreover, several boxes are assembled in one crankcase that is interchangeable for them. In addition, synchronizer assemblies are interchangeable, blocking clutches, that is, one of the most wear-prone parts of the box, while being expensive and difficult to manufacture.

Purpose and device of the checkpoint on KAMAZ

A gearbox is a unit necessary for a car, with the help of which the engine torque is changed and transmitted to the drive axles. The gearbox on KAMAZ allows you to regulate the speed and traction characteristics of the car in a fairly wide range and use the engine with the greatest efficiency.

The arrangement of boxes used on KAMAZ vehicles does not differ too much from similar units of other trucks, although they have their own design features.

The device of the most common (models 14 and 15) is as follows. The drive, driven and intermediate shafts with gears and synchronizers are installed in the common crankcase. Gears reverse gear made in the form of a separate block. Also, in the form of a separate unit installed in the upper part of the box, a gearshift mechanism is made.

Gearboxes used on KAMAZ vehicles are distinguished by their simple design, high reliability and efficiency. With proper care and normal operation, the gearbox on KAMAZ can serve for many years without causing problems.

Types and characteristics of KAMAZ gearbox

Currently, KAMAZ vehicles are equipped with several models of gearboxes of domestic and foreign production:

Model 14;

- Model 15;

- Model 161;

- Models ZF (Germany).

Model 14

Modifications 141, 142, 144. Five-speed mechanical box gears with a three-way shift mechanism. Gear shifting is carried out remotely using a rocker lever. It finds application in dump trucks and other single KAMAZ vehicles.

Model 15

Modifications 152, 154. A ten-speed manual gearbox that combines a five-speed gearbox and a front two-stage divider. Thanks to the divider, the number of speeds in the gearbox increases to 12: 10 forward and 2 reverse. Gear shifting is remote, using a rocking lever, gear shifting of the divider is pneumomechanical, carried out using a switch on the lever. They are widely used on tractors operating as part of road trains.

Gearbox modifications for KAMAZ models 14 and 15 have different gear ratios, and therefore are used on vehicles of various purposes. Gear ratios are shown in the table:

Also, these models of boxes differ in individual parts, characteristics of gears, the presence or absence of certain components, etc.

Model 161

Eight-speed manual transmission, combining a four-speed gearbox and rear-mounted planetary two-stage (reduced and direct gears) demultiplier. Products of the ZF-KAMA joint venture are manufactured in Naberezhnye Chelny.

The gearbox ratios for KAMAZ model 161 are shown in the table.