Reverse gear does not turn on the viburnum of the reason. Reverse gear does not turn on Kalina - how to solve the problem yourself

The performance of the Lada Kalina checkpoint is directly determined by which transmission substance is used. The gearbox design requires regular monitoring of the oil level. The lubricant in the unit must also be changed in a timely manner. Lada Kalina is equipped with mechanical and automatic transmission. The option of equipping one or another gearbox determines the design and operational features of the car.

The structure of the mechanical box on Kalina

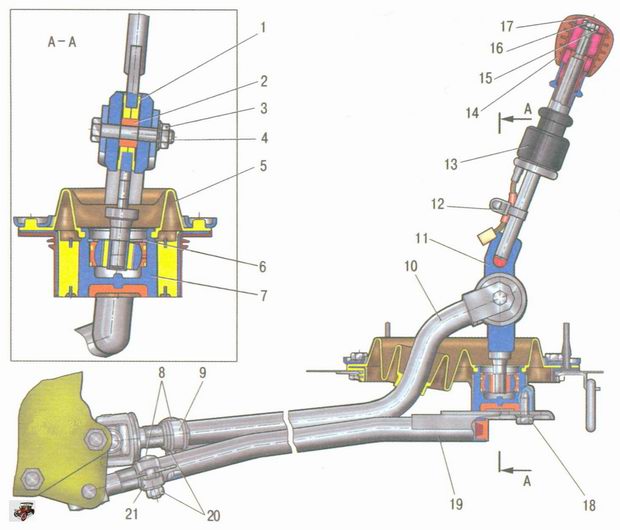

Manual transmission Lada Kalina - two-shaft design with 5 forward gears and 1 reverse. Synchronizers are installed on all forward gears. Structurally, the gearbox, differential and final drive are combined into one unit.

The manual transmission case consists of several elements:

- clutch housing;

- gearbox housing;

- rear cover of the gearbox housing.

They are cast from aluminum alloys. When assembling between the structural parts, a gasket-sealant is used, which has gasoline and oil-resistant properties. A special magnet is located in the socket of the oil drain plug of the clutch housing. It traps metal debris and prevents it from entering the Lada Kalina checkpoint.

The input shaft is represented by the drive gears in the block. Between them and the driven gears of the forward speeds there is a constant engagement. The output shaft of the Lada Kalina gearbox has a hollow structure, due to which oil is delivered to the zone of the driven gears. A removable drive gear is placed on the secondary shaft main gear, driven gears, forward gear synchronizers.

Front (roller) and rear (ball) bearings are fixed on the shafts. The radial clearance in the front bearings is not more than 0.07 mm, in the rear ones - 0.04 mm. The oil flow is directed inside the shaft through the oil sump.

The driven gear of the Lada Kalina gearbox is attached to the flange of the two-satellite differential box. With the atmosphere, the box is informed by a breather located at the top.

Gearbox control drive are:

Reverse lock solenoid

The device of the Kalina gearbox is distinguished by the presence of a solenoid to block accidental or arbitrary reverse gear. The protruding part of the solenoid core prevents the locking brackets from moving along the axes before the reverse gear is engaged. The solenoid is controlled by a switch mounted on the lever.

The solenoid is located in the crankcase of the box, its lower left side. When the ring under the handle rises, the contacts close to energize the solenoid. Its core retracts, reverse speed can be turned on. This mechanism eliminates the erroneous shift to reverse gear instead of first.

In cases of failure of the solenoid or damage to the electrical circuit, the inclusion of reverse gear becomes impossible. The solenoid will need to be replaced. It can be produced at a service station or in a garage. When the solenoid replacement is done, you will have to add oil to the gearbox. When the solenoid is everted, a certain amount of fluid flows out.

If a malfunction is found far from a parking place or a possible car repair, you will have to get there in emergency mode. For this:

- you need to unscrew the solenoid;

- in the vacated hole, put the stopper of the rod retainer (from the gearshift fork).

While the machine is moving, care must be taken not to engage reverse instead of first gear. The diagram of the device will help to independently install the solenoid on the gearbox. The replacement itself is a process that is not particularly difficult.

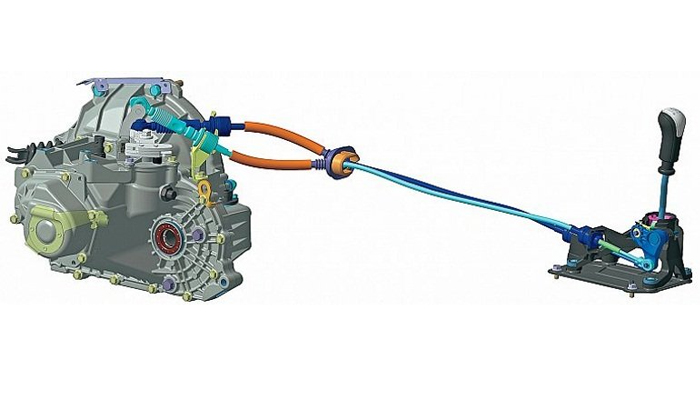

Design features of Kalina with automatic transmission

Cars Lada Kalina, having a 16-valve gasoline engine with a volume of 1.6 liters, are equipped with automatic transmission. The rest of the models are still equipped with a manual gearbox.

The constructive replacement of a manual transmission with an automatic transmission led to the fact that the car began to differ in a number of features:

All this is a kind of payment for comfortable driving. Some companies propose to change the design of the automatic transmission and bring it to sports class. This changes the operation of the entire transmission, and the car becomes very noisy.

Gearbox maintenance

To maintain the normal operation of the gearbox, it is necessary to systematically monitor the oil level. Perform procedures should be on a cold box. The desired oil level indicator is located between the two control marks printed on the pointer.

You can use the dipstick to determine how much fluid to add. It is better to pour the substance in small doses through the hole closed by the probe.

The operating manual for Kalina defines the filling volume of the box as 3.1 liters. But practical advice according to how much to fill the transmission substance, they differ slightly from the normative ones. More often they say that a complete fluid change requires 3.3 liters.

For Kalina's gearbox, clear parameters are defined, according to which the planned replacement of the transmission substance is carried out. High-quality oil fulfills 75,000 km or 5 years of car operation. Depending on what comes first, the transmission substance is replaced.

Recommendations for the use of transmission oils for Kalina

Adding oil or replacing it in Kalina's gearbox will require an answer to the question of which substance to choose. It is best to follow the manufacturer's recommendations. The machine manual lists the different oils. They are classified by:

It is important which substance ensures stable operation of the gearbox in the widest temperature ranges. This is an oil with a viscosity marking of 75W-90. It guarantees lubrication of units at temperatures from -40° to +45°.

And which gear oil has more universal performance? This can be considered a substance whose viscosity is indicated 80W-85. If this oil is filled in the Kalina gearbox, then the normal operation of the units is maintained in climatic conditions from -26° to +35°.

Regardless of which oil is planned to be used in the Kalina box, it is strongly recommended not to use various additives or other means. The use of highly efficient gear oils does not require additional additives. Moreover, in some cases, the use of additional additives can lead to damage to the gearbox or other transmission units.

Original German autobuffers Power GuardAutobuffers - save money on suspension repairs, increase ground clearance+3 cm, quick and easy installation...

Official website >>>

Many problems with reverse gear on Lada Kalina can be diagnosed and then eliminated by drivers with minimal time losses with their own hands. To do this, it is not necessary to contact a car service and pay money for the services of specialists.

1 What is a common reason why reverse gear cannot be started?

If it doesn't turn on reverse gear on Kalina, beloved by domestic motorists, you do not need to immediately go to the technical center. Usually a similar problem is solved in a couple of hours in a private garage. Often the reason for the incorrect behavior of the iron horse of the brand we are interested in is a malfunction of the electrical wiring in the gearbox (gearbox). On Kalina, reverse gear is started by pushing the gearshift lever down and locking it in first gear. After performing such actions, the solenoid is activated in the box. Its task is to redistribute the gears so that they effectively transfer the load of rotation against their axis (that is, to ensure driving at reverse speed).

In fact, the machine, working in first gear, moves in reverse due to a special additional gear connected to the lever mechanism. This simple circuit ceases to function in cases where the wires in the specified solenoid rot. You can easily solve this problem:

- We turn out until it stops (to the side) the front left wheel.

- We raise the hood.

- We release with the key 36 a special washer that tightens the solenoid housing. Carefully dismantle it.

- Blue and yellow wires come out of the case. It is they who may be responsible for the fact that the reverse gear does not work.

- If we see that the wiring is rotten or covered with a thick layer of moisture and oil, we change them.

- Put the solenoid housing back.

- We start the Lada Kalina, drive 20-30 meters in first gear, turn on the reverse gear.

The entire procedure described takes about 40-50 minutes. But sometimes the actions taken do not solve the problem. Then it makes sense to check the operation of the toggle button. The wires leading to it also rot quite often. We remove the rubber gasket and the lever itself right in the cabin. Inspect the switch for broken wiring. If there is one, we replace the damaged wiring.

After dismantling the lever, be sure to inspect it for signs of corrosion. Very often, ingrained rust locks the switch button, preventing reverse gear from being turned on. We remove corrosion, put the lever and the gasket back. Let's try the back. If after that it does not work, we are looking for other reasons causing the malfunction.

2 Reed switch and bearing failures - such misfortunes also happen

Consider other common reasons that do not allow the use of reverse on conventional and tuned and. Perhaps the reed switch flew. The performance of this element is easy to check. We dismantle the decorative casing above the lever in the passenger compartment and look for a connector for its connection. We extract the latter and close the contacts. This operation can be performed with a piece of wire, a paper clip, or any other suitable device at hand.

After a mechanical circuit of the wiring, we try to turn on the reverse speed. If the problem is solved, leave everything as it is. We go about our business. And at the first opportunity we go to a car service and completely change the reed switch. It is impossible to operate a car with wiring closed according to the specified scheme for a long time. Note that the failure of the reed switch is most often caused by the decay of its contacts or the ingress of small particles of dirt and debris into the mechanism.

IT IS IMPORTANT TO KNOW!

Every motorist should have such a universal device for diagnosing his car. Now without an autoscanner just nowhere!

Read, reset, analyze all sensors and configure on-board computer car you can independently with the help of a special scanner ...

It makes sense to check the reed switch when, when you try to turn on the reverse gear, you do not observe any reaction from the machine. The gear selector simply does not go down, no matter how hard you push it.

If the reverse gear is engaged, but the driver does not hear the characteristic sound with which the additional gear comes into operation, we can safely talk about a malfunction of the release bearing. It usually breaks down due to metal filings or used oil that has penetrated the gearbox mechanism. These contaminants increase the friction force. This causes rapid wear of the bearing, and in some cases leads to the combustion of the entire mechanism. The described problem is solved in one way - you need to install a new bearing.

3 We repair the solenoid - all operations for independent work

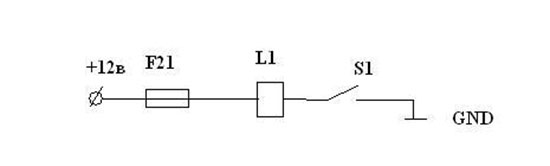

We have already told you how to replace the wires leading to the solenoid. Now let's deal with the rules for repairing the Kalina locking mechanism. Its malfunction leads to the inability to turn on the back. To perform such a repair, you need to look at the solenoid control circuit. It is shown below.

The failure of the mechanism in most cases is due to the failure of the F21 fuse (it is designed for 10 A). Through it, as seen in the diagram, 12 V is supplied to L1 (solenoid). Then S1 (switch) closes the circuit to ground. As a result of this, the solenoid coil is activated. If the fuse is blown or the switch fails, reverse gear will be blocked. We solve this problem. We take out the fuse (if you look at the left, it will be the eighth one), check it with a multimeter. Instead of a faulty element, we put a new one (strictly of the same rating - 10 A). When F21 works, we deal with the switch (see the first section of the article).

If replacing the switch and fuse did not work, remove the connector from the solenoid. We put ordinary pins in it (two pieces). We measure the voltage with a multimeter. With a normally working mechanism, it is equal to 12 V. If the readings are different, we have a break in the electrical harness on the pallet - at the place where the clamp is mounted. We pull out the entire harness, expose the wires, eliminate the break. We solder the place of twisting and, for greater reliability, we process it with heat shrink.

In very rare cases, the solenoid itself breaks. You can verify its malfunction with a multimeter. We connect the device to the solenoid and measure the resistance. If we see an indicator other than 2.2 Ohms, we will have to change the element. The work is simple, but quite dirty. You will need to drain the oil from the gearbox, then remove the old one and install a new solenoid. Before installing a serviceable element, we must process the thread with a sealant. It is important. Without such a procedure, oil will soon begin to seep through the thread.

4 Why reverse gear does not turn on - other reasons

If the described methods for restoring the normal functioning of the box did not help, most likely we encountered problems in the mechanical part of the gearbox:

- spring burst;

- the fixing bolt was cut off;

- the device that fixes the elements of the gearbox has broken.

These malfunctions are truly complex. Car service specialists should solve such problems, since it will be necessary to remove the gearbox, disassemble it, find the cause of the breakdown, and then fix the problem. All this takes more than one hour of time and requires the use of special tools. Doing such repairs at home is irrational.

Do you still think that car diagnostics is difficult?

If you are reading these lines, then you have an interest in doing something yourself in the car and really save because you already know that:

- Service stations break a lot of money for simple computer diagnostics

- To find out the mistake you need to go to specialists

- Simple wrenches work in the services, but you can’t find a good specialist

And of course you are tired of throwing money away, and it’s out of the question to ride around the service station all the time, then you need a simple ELM327 AUTO SCANNER that connects to any car and through a regular smartphone you will always find a problem, pay off the CHECK and save a lot! !!

We have tested this scanner ourselves on different machines and he showed excellent results, now we recommend him to EVERYONE! So that you do not fall for a Chinese fake, we publish here a link to the official Autoscanner website.

During the operation of the car, various malfunctions can occur, there are breakdowns that are most typical for each car model. On Lada Kalina, car owners quite often encounter a problem - the reverse gear of the manual transmission does not turn on, and when such a defect appears, many car owners tune in for serious repairs. But the breakdown occurs for various reasons, the fault can be both mechanical and electrical parts. In order not to do extra work, you need to start looking for the defect that has arisen from the most elementary, maybe the wire has simply frayed, or there is a bad contact in the plug.

Reasons for the loss of reverse gear VAZ 1118

To find out why there may be no reverse gear on a VAZ car, you need to understand what kind of design is here, what parts and assemblies it consists of. The reverse gears themselves (ZX) are located inside the gearbox, in the housing, as well as the gear selection mechanism, outside the crankcase are located:

- two backstage (jet thrust);

- shift lever (RP);

- a solenoid that blocks the ZX, screwed into the gearbox housing from the outside;

- locking ring located on the lever stem;

- switch located in the gear knob.

The reverse gear interlock (RP) protects the gearbox from accidental engagement, and to enable the ZX, you need to lift the locking ring up, move the lever first to the left as far as it will go, and then move forward. But sometimes it happens that even with the switch raised, the RFP refuses to work, the RP stubbornly does not want to take the desired position.

The reverse gear interlock (RP) protects the gearbox from accidental engagement, and to enable the ZX, you need to lift the locking ring up, move the lever first to the left as far as it will go, and then move forward. But sometimes it happens that even with the switch raised, the RFP refuses to work, the RP stubbornly does not want to take the desired position.

So, why does reverse gear not turn on:

- there are defects on the gears of the RFP;

- there is no normal clutch release;

- the spring on the axis in the gear selection mechanism has broken;

- solenoid not working

- the sensor contacts do not close;

- there was a break in the wire supplying power to the blocker;

- fuse F21, which is responsible for the operation of the blocking device, has blown.

Troubleshooting in the electrical part of Lada Kalina

A break in the wire of the RFP switch on a Lada Kalina car occurs quite often, this is due to the fact that the RP often changes its position, respectively, and the wiring is not at rest. Checking if the solenoid itself is working is quite simple, here you need:

If the RFP appeared, it means that everything is in order with the switch itself and the manual transmission, it's all about the wiring or poor contact of the plug. After such a diagnosis, the paper clip will need to be removed, it is highly not recommended to drive constantly with the contacts closed on the connector.

In some cases, a break is detected immediately after lifting the gearbox cover, but often the wires fall off in the area of \u200b\u200bthe solenoid of the blocking device. To carry out diagnostics, you should install the VAZ Kalina on a pit or car lift, and conduct a visual inspection. Most often, a break occurs in the immediate vicinity of the sensor, since this place is not protected by anything here - dirt and moisture, rubble and pebbles fly from the road.

When the wiring is still in the factory braid, it is sometimes difficult to detect any damage. The contact may periodically disappear and then reappear, the defect turns out to be floating, in which case it is necessary to open the insulating protection.

When the wiring is still in the factory braid, it is sometimes difficult to detect any damage. The contact may periodically disappear and then reappear, the defect turns out to be floating, in which case it is necessary to open the insulating protection.

It is also worth noting that a similar defect is often found on Kalina, is typical for this car, such a breakdown can occur even on a car with relatively low mileage (40-50 thousand kilometers). The problem occurs because:

- the wires are too short, they should have been made a few centimeters longer;

- insulation is of poor quality, often cracking in the cold.

So before looking for malfunctions in the mechanical part, you need to check the electrician.

Reverse gear Lada Kalina is not blocked

Another malfunction is directly opposite to the one described above, in this case the lock does not work, and reverse gear is engaged in any case, regardless of whether the ring is raised or not. Driving a car without a ZP blocker is not very comfortable, there is a risk of spoiling the gearbox (especially for beginners) by turning on the rear instead of lowering the first speed. There are also several reasons for the problem:

- the contacts of the button inside the manual transmission handle are stuck;

- there is a short circuit in the wires going from the box to the lever;

- stuck solenoid.

Checking the condition of the push-button contacts of the blocker is quite simple: we raise the cover of the gearshift lever, disconnect the plug. If the guess turned out to be correct, ZX will be impossible to turn on.

How to replace the solenoid switch

The solenoid can go sour in the open position, in some cases light tapping on its body helps. It is characteristic that sticking occurs when the car is on a steep slope. Breakdowns also happen on the way, and if the sensor fails, and it is impossible to turn on the reverse speed, you can unscrew it a little from the box for a while (about 7 turns), then the RFP will appear. But you need to understand that this is a temporary measure, when the solenoid fails, it needs to be changed.

Before replacing, it will not be superfluous to check the sensor, this is quite simple to do. It is necessary to disconnect the wires from the chip, apply a voltage of 12 volts to the contacts, at the moment of supply, a noticeable click should be heard in a working solenoid.

Before replacing, it will not be superfluous to check the sensor, this is quite simple to do. It is necessary to disconnect the wires from the chip, apply a voltage of 12 volts to the contacts, at the moment of supply, a noticeable click should be heard in a working solenoid.

Before starting work, we prepare:

- capacity for transmission oil;

- key for 36;

- sealant.

A similar operation must be performed in a pit or a car lift, the oil from the gearbox may not be drained, but it is better to do it anyway in order to do the job more accurately. We replace the part in the following order:

Replacing the reverse switch (reed switch) in the gear knob

To replace the reed switch located in the "knob" of the manual transmission handle, you will need the 13th key and a flat screwdriver with a sharp end. To get to the switch, you need to pry off the top cover from the handle, this can be done with a screwdriver.

Then:

Then:

- unscrew the handle fastening nut (key thirteen), it is even more convenient to dismantle the parts using a 13 mm head and a knob;

- after the nut is removed, dismantle the handle itself by turning it counterclockwise;

- remove the leatherette casing, disconnect the plug with the wires that supply power to the solenoid, remove the reed switch;

- we mount a new switch, we install all the parts in their places.

Replacing the Gear Selector

Another reason why reverse gear may not engage is a malfunction of the gear selection mechanism. As a rule, a defect occurs due to a broken spring in this assembly. To fix the problem in this case, you have to remove and disassemble the gearbox, the work turns out to be laborious, it takes a lot of time. To get to the mechanism, we perform the following operations (we list only the most basic ones):

Of course, only the spring can be replaced in the mechanism, but this is provided that the parts in it are not worn out. Practice shows that it is easier and more reasonable to install a new part in the assembly - there is no guarantee that the repaired mechanism will not present any "surprises", and it is relatively inexpensive. It should be noted that with a broken “selection” spring, it is still possible to turn on the rear speed in some cases, but always with great difficulty.

Other reasons for the lack of reverse gear VAZ-1118

The RFP may still not turn on if the rocker (jet thrust) is not adjusted, but in this case, problems will also arise when trying to turn on some other speed (for example, first or fifth). That is why, with any removal of the manual transmission, it is recommended to put marks on the wings in order to install it in exactly the same position during assembly.

Another reason for the failure of the ZX is an unadjusted or poor clutch, but here, too, other gears either do not turn on or switch with a crunch. The travel of the clutch pedal on Kalina is regulated by reducing or increasing the length of the cable, with a worn disc, the car starts to drive with slipping, gaining momentum poorly. One of the main signs of a bad ferrodo is the smell of burnt linings, it is especially noticeable when the car is gaining momentum, working with increased load. This also increases the free play of the clutch pedal, and it is not always possible to adjust it.

The gearbox is a car unit, even a minor defect of which drastically affects the comfort and safety of the vehicle. A breakdown on the road can lead to an accident. In order to avoid tragic consequences, it is recommended to properly care for the unit, repair it if necessary, or change it.

Checkpoint Kalina often acts as a weak link of the specified brand of car. But not always problems are caused by assembly defects. The user factor is the main cause of breakdowns in the Lada Kalina checkpoint. And first of all, this is due to non-compliance with the rules for caring for the mechanism.

When the malfunction is already present, there is only one thing left - repair. The easiest way is to drive the car to the service station. This is where the technicians will diagnose. Checkpoint VAZ Kalina, sort out the node, replace the faulty elements.

Repair of checkpoint Kalina- 2000 r.

Exchange of checkpoint Kalina with installation- 6000 r.

Box repair

Car owners Kalina gearbox repair it is recommended to trust professionals. The guarantee of the quality of work is worth the investment made. Every motorist traveling to a service station is concerned about the question of how much it will cost him to repair the Kalina checkpoint, the price of such a repair depends directly on the complexity of the breakdown, the quantity and quality of the spare parts used. The type of service also plays a role. Overhaul cost more than planned. This involves the execution by the masters of the diagnosis of the box, removal, disassembly of the assembly, troubleshooting. After the mechanism is assembled, adjusted, installed in place.

In order to save money, many car owners limit themselves to self-repair. It is worth noting that if you have a Lada of any model, including Kalina 2, it is very problematic to diagnose a checkpoint without special equipment. Missed details can play later fatal role. IN best case poor-quality repairs will lead to additional expenses. Checkpoint price for Kalina high enough. Replacing the node will be an expensive pleasure. Pay twice or entrust the restoration of the performance of the Lada Kalina 2 checkpoint to any other professionals and get guarantees, it's up to you.

Replacement is an alternative to repair

Overhaul of the box is not always advisable. Its cost can be quite high. In addition, you will have to do without a car while it is in service. An alternative to repair can be the purchase of a used gearbox, Kalina is a popular car, spare parts are presented in assortment at disassembly. It will not be difficult to pick up a node for any model of machine.

Need Checkpoint Kalina sport? Buy a used unit for parsing. It's cheaper than renovating an existing one. In addition, it is beneficial in saving time. Replacement of the box is carried out by the service masters promptly. flew Checkpoint VAZ 1118 Kalina? Pick up a replacement on parsing. Companies operating in the market sector offer a wide range of spare parts. These are carefully checked before being sold. Only spare parts with an undeveloped working resource are supplied for sale. As a result, the car Kalina KPP 2181, another model, you can purchase the original, tested in real road conditions (guaranteed without manufacturing defects) and at an affordable price.

You can, of course, purchase a spare part “from hand”. It is enough to advertise “I will buy a checkpoint on Kalina » or « viburnum manual transmission 2181» in the electronic media. But in this case, there is a high risk of running into an unscrupulous seller. If the price offered at the Lada Kalina checkpoint is too low, this should alert the buyer. Everyone knows where free cheese is offered. Checkpoint Lada Kalina buy second-hand can be in the car market. The risks are similar.

Repair or change the node, everyone decides on their own. Do you want to optimize costs and save time? Your choice is to exchange the box.