Knock sensor vaz 2114 8 valves. VAZ knock sensor

The current availability of car service services does not relieve the car owner from the need to know the signs of a malfunction of the VAZ 2114 knock sensor and other machine components. You need to be friends with her, you should listen to her - and then you will drive a car, and not lie under it (or pay rather big sums for the corresponding work). As for DD, you should not think of it as something insignificant, correlating its functions with small sizes.

The staffing of the engine depends on this sensor: it controls the moments of detonation, often determines its causes, transmits information to the onboard “brains”, which correct the ignition timing and adjust the ignition of the mixture entering the engine.

"Later ignition" is one of the illustrations of the joint operation of the control system and the knock sensor. If the process is not regulated, certain components (in particular, connecting rods) will constantly overheat, they wear out faster, more and more often, various maintenance repairs are required, and then capital.

Symptoms of a malfunction of the knock sensor VAZ 2114 can be determined from indications on-board computer, and the behavior of the car itself.

anxiety symptoms

- The engine starts to tune. This is to say that DD does not send signals to the control system, and it does not adjust the ignition timing;

- The dynamics deteriorate noticeably, the machine;

- Acceleration becomes slow, the engine roars, and the car picks up speed slowly;

- “ ” lights up when starting off, when going downhill, and when accelerating. Moreover, if the "Check" is on only when the ignition is turned on, and after 6 seconds it goes out - this is normal: the "brains" are testing all the components of the machine.

Hints from the computer

The on-board system can let you know what is wrong with the DD if it was able to determine the location of the failure. You just need to remember the error numbers:

- Code 0325 indicates that there is a break in the power wire. The most common version of what happened is the oxidation of the contacts, the wiring itself breaks extremely rarely. Stripping the terminals in most cases eliminates trouble. However, if the error has not disappeared after processing, you need to check the timing belt: it means that it jumped a few teeth. the problem disappears;

- 0328 in most cases, it signals a malfunction of the high-voltage wires, but in some cases it can again report a belt jump;

- 0326 and 0327 talk about a low signal coming from the knock sensor. There are 2 options here: either the DD tightening loosened up, or the contacts were oxidized again.

Sensor test

If the connections are normal, and the “Check” is on, you will have to start diagnosing the sensor itself. It is located rather inconveniently, between the 2nd and 3rd cylinders (this gives him the opportunity to take readings from the entire block). To check, we perform the following algorithm:

- Turn off the ignition and climb under the hood;

- If there is a 2-pin knock sensor, the nut is twisted with a 13 key, if it is 1-pin, the tool is taken at 22;

- The multimeter (or voltmeter) is set to operate with a maximum of 200 MV;

- The electrodes of the device are connected to the terminals DD. Officially, it is believed that the voltmeter indicator (say, there is voltage) is enough. However, experienced drivers do not think so: the sensor must respond to shocks caused by detonation. Therefore, additional studies are being carried out: the sensor is lightly tapped with a screwdriver handle; during impacts, the meter readings should change. If they remain constant, the DD needs to be replaced.

Each car provides in its design a large number of different sensors. These devices are necessary in order to monitor the condition of the main components of the car and transmit information to the electronic control unit. The ECU, based on the data received, corrects the operation of a particular system and makes appropriate changes if necessary.

The knock sensor on the VAZ-2114 is located between the engine cylinders. This arrangement allows you to get the most efficiency from this simple, but extremely important mechanism. What is the main purpose of the knock sensor and what are the main signs of its malfunction?

.jpg" alt="Knock sensor VAZ 2114" width="600" height="518" class="lazy lazy-hidden aligncenter size-full wp-image-3812" srcset="" data-srcset="https://vazremont.com/wp-content/uploads/2017/08/foto-1-8..jpg 300w" sizes="(max-width: 600px) 100vw, 600px">!}

How the sensor works and why it is needed

The operation of the mechanism is based on the principle of a piezoelectric element. This means that if a vibration of a different nature occurs in the engine cylinder, a signal to the ECU will be transmitted using electronic pulses. In turn, the final element in this chain will make changes to the operation of the ignition angle.

This algorithm of actions allows you to protect components and parts from mechanical damage. On the "fourteenth" in most cases there are broadband mechanisms, but often the manufacturer also installed a resonant type of device, most often on the very first copies of the VAZ-2114

data-lazy-type="image" data-src="https://vazremont.com/wp-content/uploads/2017/08/foto-2-7..jpg 687w, https://vazremont.com/ wp-content/uploads/2017/08/foto-2-7-300x221..jpg 660w" sizes="(max-width: 687px) 100vw, 687px">

The fundamental difference between the resonant type device is that it is able to capture only the noise of the detonation frequency.

The broadband mechanism outperforms its counterpart in that it has a wider range of possibilities. Such a sensor is able to capture noise of various frequencies, which, of course, gives the vehicle system additional stability.

The devices operate according to different principles, therefore, in the event of a breakdown of the resonant sensor, it cannot be replaced with a broadband one. The situation is similar in the opposite case. If there is an urgent need to replace and change the principle of operation of the mechanism, you will have to purchase a new control unit.

The main symptoms of a malfunction

Data-lazy-type="image" data-src="https://vazremont.com/wp-content/uploads/2017/08/foto-3-8.jpg" alt="Knock sensor malfunctions" width="600" height="450" class="lazy lazy-hidden aligncenter size-full wp-image-3814" srcset="" data-srcset="https://vazremont.com/wp-content/uploads/2017/08/foto-3-8..jpg 300w" sizes="(max-width: 600px) 100vw, 600px">!}

If the VAZ-2114 knock sensor has begun to function incorrectly, then in most cases the driver will be able to notice a flashing Check Engine indicator on the dashboard. At the same time, it is easy to notice a malfunction by the very behavior of the car. The car does not accelerate well, does not overtake, “suffocates” when going uphill. The engine is unstable and shows obvious signs of failure. Other symptoms should include:

- frequent overheating of the motor;

- at hard pressing a detonation knock is clearly audible on the gas pedal;

- the on-board computer gives an error, the decoding of which indicates a sensor malfunction.

Detonation knocks often occur due to low-quality gasoline. In the presence of all of the above symptoms, it is best to conduct a complete computer diagnostics of the car. Monitoring will allow you to determine at what stages of engine operation the worst performance is observed, as well as computer diagnostics will allow you to find out the knock sensor error code.

Diagnostics can detect such malfunctions as an open circuit, an excess of the signal level or its too low value.

If the diagnostics has determined a malfunction of the knock sensor, you must still make sure that the device is not functioning correctly.

Checking DD at home

Data-lazy-type="image" data-src="https://vazremont.com/wp-content/uploads/2017/08/foto-4-8.jpg" alt="Check knock sensor" width="687" height="516" class="lazy lazy-hidden aligncenter size-full wp-image-3815" srcset="" data-srcset="https://vazremont.com/wp-content/uploads/2017/08/foto-4-8..jpg 300w, https://vazremont.com/wp-content/uploads/2017/08/foto-4-8-660x496.jpg 660w" sizes="(max-width: 687px) 100vw, 687px">!}

How to check the knock sensor VAZ 2114 at home? It is possible to determine the operability of the mechanism using an ohmmeter or a digital voltmeter. The first allows you to determine the resistance, and the second - the voltage between the contacts. A properly functioning knock sensor VAZ 2114 has almost infinite resistance. If this indicator is completely absent, then the mechanism must be replaced.

The procedure for measuring voltage with a voltmeter is as follows:

- Set the limit on the device to 200 millivolts.

- Connect the voltmeter probes to the DD contact.

- It is necessary to knock on the sensor body without force, for example, with a screwdriver.

- Record the digital voltmeter reading.

Various indicators are possible, since the figure in most cases depends on the force of impact on the body. Further, comparing the obtained indicators, you can begin to replace the DD. If the digital voltmeter did not display any numbers at all, this indicates that the DD is completely out of order and needs to be replaced urgently.

How to replace the sensor

Data-lazy-type="image" data-src="https://vazremont.com/wp-content/uploads/2017/08/foto-5-8.jpg" alt="Replacing broadband DD" width="550" height="413" class="lazy lazy-hidden aligncenter size-full wp-image-3816" srcset="" data-srcset="https://vazremont.com/wp-content/uploads/2017/08/foto-5-8..jpg 300w" sizes="(max-width: 550px) 100vw, 550px">!}

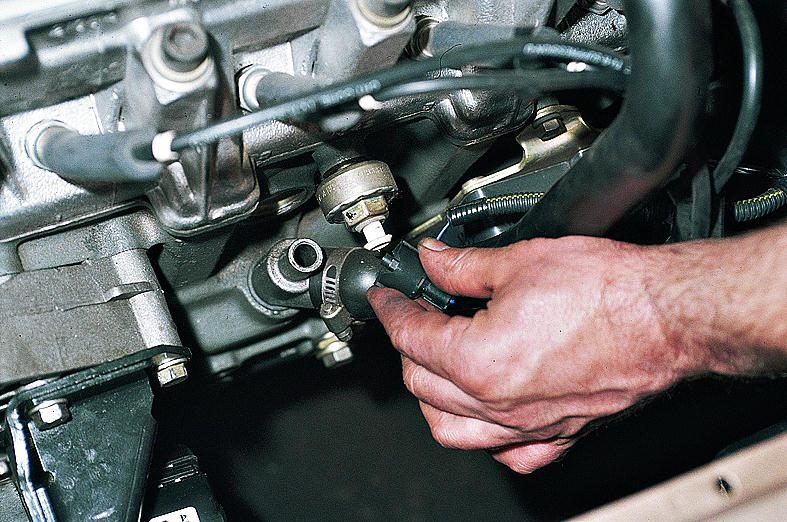

Replacing the mechanism yourself is not a big deal. It is located between the second and third cylinders, you need to open the hood and provide yourself with unhindered access. It is important that the engine is turned off during this time. As soon as DD is detected, it is necessary to disconnect the plug going to the sensor wires.

If the mechanism is broadband, then to do all the work you need a key to "13". In the case of a resonant device, you should arm yourself with a key on "22". It is only necessary to unscrew the nuts from the stud with a key to “13” or the piezoelectric sensor itself with a key to “22”. It is also necessary to clean the contacts with sandpaper, remove all dirt and oxidation. Do not neglect this procedure, because the quality of the transmitted signal depends on the state of the contacts.

.jpg" alt=" Resonant DD replacement" width="550" height="366" class="lazy lazy-hidden aligncenter size-full wp-image-3817" srcset="" data-srcset="https://vazremont.com/wp-content/uploads/2017/08/foto-6-6..jpg 300w" sizes="(max-width: 550px) 100vw, 550px">!}

Oxidation and various kinds of plaque impede the transmission of a high-quality signal. As a result, this leads to a decrease in the level and accuracy of the pulse, which will leave its mark on the operation of the car. After that, you need to install a new mechanism and assemble in the reverse order.

Useful video

Other useful information you can watch the video below:

17.09.2012

Where is the knock sensor located? To find the answer to the question of where the knock sensor is located, pay attention to the figure. It is located between the second and third cylinders on the engine block on the radiator side.

The engine knock sensor on the VAZ is available in 2 types:

- Resonant (is the shape of a barrel).

- Broadband (shaped like a tablet).

The two types are not interchangeable, so choose the correct sensor when purchasing.

There are also sensors:

- Single contact sensor.

- Two-pin.

What is a knock sensor for?

The knock sensor ensures the normal operation of the engine. If the knock sensor is broken, then this will lead to engine tripping, increased gas mileage. We figured out what the knock sensor is for, now we need to find out the principle of operation.

Principle of operation

The knock sensor monitors engine knocks. The stronger the blow, the more voltage the sensor supplies to, which, in turn, correctly builds the ignition timing. In other words, if detonation occurs in the engine, then the sensor will delay the ignition for normal engine operation.

Symptoms of a Failed Sensor

- engine.

- Low car dynamics.

- The check rage light came on when starting uphill.

- The check rage light came on when the car was accelerating.

If one of these points bothers you, then the knock sensor may be faulty. For a more accurate diagnosis, check the knock sensor ().

If your on-board computer gives an error about a malfunction of the knock sensor, then see the article:.

Each car today is equipped with various regulators and controllers designed to control and manage different systems. One such on the car is detonation. You can learn more about the purpose, types and process of replacement from this material.

Purpose and principle of operation of the sensor

On 8- and 16-valve engines, the VAZ 2110 performs the function of controlling the ignition system of the combustible mixture. Due to late ignition, the driver may face the problem of increased gas mileage, a decrease in engine power, and also its overheating. If the ignition of the combustible mixture is later, this can lead to valve burnout and also a decrease in engine power.

As for the principle of operation of the device on an internal combustion engine of 8 or 16 valves, it lies in the piezo effect. That is, the voltage level depends entirely on the physical impact on the component. If the pressure is higher, the voltage pulse will increase accordingly.

Varieties

If we talk about the types of VAZ phase sensor, then in domestic "dozens" the following types of regulators can be used:

- broadband controller;

- resonant device.

In broadband versions, the ADC converter perceives the impact of all current pulses that the device generates. If a resonance suddenly appears in the system, then the measuring unit can only perceive vibrations at a particular frequency, which is relevant for the moment of detonation in the motor.

It should be noted that the two types are not interchangeable per se, as they have significantly different pulse levels. So if you are faced with a problem with the device malfunctioning and, accordingly, with the need to replace the knock sensor, then it is better to install the same regulator that was already standing (the author of the video is the Engine Repair channel! And interesting!).

Common faults

Before you change the device on the 8 valve motor, you need to take the time to diagnose it, for this, first of all, check the power wiring. As practice shows, often the error of the phase sensor is due to the oxidation of the contacts, if this is the case, then they will only need to be cleaned. Usually this regulator is very reliable, signs of malfunction in its operation are rare.

But if the controller breaks down on an 8 or 16 valve motor, you can either check it with a computer or analyze the symptoms of a malfunction:

- drop in power of an 8- or 16-valve engine;

- from time to time, the Ckeck Engine indicator may appear on the dashboard, especially when increasing power, at the very beginning of the ride or when driving uphill;

- signs of malfunction also include engine tripping - when driving at low speeds, the engine starts to shake;

- auto self-diagnosis will also show errors 0325, 0326, 0327, 0328, which indicate a malfunction in the electrical circuit of the device.

Functionality check

How to check the knock sensor with your own hands? For diagnostics, you will need a multimeter, which should first be configured to work in the 200 mV range. To check the performance of the regulator, it is necessary to connect the probes of the device to its connectors. If a resonant controller is installed on your "top ten", then in this case one probe should be connected to the case.

Then you need to knock on the body of the device with a screwdriver. As you remember, the voltage readings that the tester considers will depend entirely on how strong the impact on the sensor is. That is, the stronger the blow with a screwdriver, the greater the voltage signal. In the event that this dependence takes place, then the tested regulator is fully operational.

After that, the multimeter should be switched to measure the resistance parameter. Ultimately, the diagnostic indicators obtained on a working device should be from 1 to 10 MΩ. In the event that the controller is faulty, then the resistance parameters will tend to infinity, and if the sensor is broken, then the values \u200b\u200bwill be 0.001-0.09 Ohm.

Replacement instructions

In the event that the car began to behave worse on the road, and the check showed a failure of the controller, most likely it will be necessary to replace the knock sensor VAZ 2110. To replace you will need the device itself and a little time, in general, the replacement procedure is not complicated and can be completed in a few minutes.

Do the following:

- First you need to understand where the controller is installed. In the case of the "ten", the regulator is mounted on the engine housing in the engine compartment, in particular, you can see it between 2 and 3 cylinders. Not far from the installation site, there is also a dipstick for measuring the level of engine fluid.

- After that, make sure that the ignition is off, and you can disconnect the power wiring from the device.

- Using a wrench for 12 or 13, in this case it all depends on the type of controller, it is necessary to unscrew the fixing nut, after which the device is dismantled and replaced with a new one.

The principle of operation of such a device as a knock sensor is similar on all modern vehicles. This device has sufficient reliability and consists of a homogeneous monolith with an integrated special plate with a piezoelectric element that responds to the impact of the desired frequency. It is this wave action with a certain frequency that is formed in the cylinder block of the power plant when the air-fuel mixture is burned.

An electric current with a voltage of several millivolts, which appears as a result of this effect, serves as the source of measurements that are fed to the car on-board computer. And already the electronic system of the vehicle corrects the value of the ignition timing, neutralizing by these actions the possible shock effects that occur during the detonation of the fuel.

Despite the fact that the VAZ 2110 knock sensor, the price of which is quite acceptable, has small linear dimensions and is very simple in design, its importance cannot be overestimated. After all, the loss of a switching signal from this product leads to the display of the corresponding failure code on the on-board computer display, which is decoded in the VAZ 2110 as a knock sensor error and leads to the transfer of the computer to a safe operating mode.

This, in turn, optimizes the program costs of the electronic control unit, adjusts the ignition timing to the minimum value, which leads to an increase in fuel consumption and a decrease in the dynamic power of the car.

In the event of a break in the knock sensor, the car is in operation for some period of time without this setting. The same applies to the case when malfunctions are detected in the knock sensor, but it is not possible to replace it. In any case, it is not worth delaying repairs or replacing this device.

Knock sensor - malfunctions during operation

To troubleshoot the knock sensor, you need to know where it is located in the power compartment of the car. Its location is not far from the oil dipstick at the top of the cylinder block.

Sometimes a defect can be eliminated by simply tightening or loosening the fasteners of the product to the motor, the tightening force should be within 20 Nm. This type of tightening force is best controlled with a special torque wrench. In the case when the adjustment did not give a positive effect, it is necessary to check the knock sensor VAZ 2110 with its subsequent replacement with a new product.

The search for a malfunction in the knock sensor must be carried out on a special stand, which is equipped with service stations or repair shops. At home, you can try to repair the VAZ 2110 knock sensor if you have basic concepts in electrical engineering and a motorist can use a tester or similar device with millivoltmeter and megohmmeter scales.

The procedure for determining a malfunction of the knock sensor is as follows:

- Before checking the knock sensor, it must be removed from power unit. To do this, by pressing the latch, disconnect from the terminal block.

- Unscrew the fastener nut and dismantle the product by removing it from the stud.

- To diagnose the removed device, it is required to power it to the terminals of the multivoltmeter, setting the minimum measuring limit.

Important: you should know that for a knock sensor with one contact with a black wire that is associated with a negative contact, the connection is made to the mounting socket of the mounting bolt, and the red wire of a positive direction must be connected to the signal contact in the shoe connector.

Replacing the knock sensor

The frequency of work to replace the knock sensor "dozens":

- Disconnect the power negative wire from the battery.

- Disconnects the product wiring from the wiring harness.

- We remove the fixture of the product and dismantle it.

- To activate the knock sensor, it is necessary to knock on the body of the product.

- With a working device, the product will show jumping values of the potential difference in the limits from 40 to 200 mV.

If necessary, it is possible to measure the resistance of the internal contour of the part. It is important to remember that this value for devices of this type is very large, tending to infinity.

In the absence of at least one indicator (resistance or voltage), you need to buy a new product and prepare to replace the VAZ 2110 knock sensor, since there are no other ways to resuscitate it.