Gap valve bronze bushing on the internal combustion engine. Blog › Bronze valve guides

Engine. Part 2. Preparation and start of work.

Engine. Part 3. Slipway and disassembly of the cylinder head.

In the previous part, we prepared the cylinder head of our "Ryzhik" for machining.

But first, something needs to be cleared up. The fact is that we do not have ball cutters for boring channels. There are also no tools for high-quality cutting of saddles. There is not even a sweep for the guides.

For the sake of a one-time repair, there was no point in buying these expensive tools, so we had to resort to the help of craftsmen to perform these works.

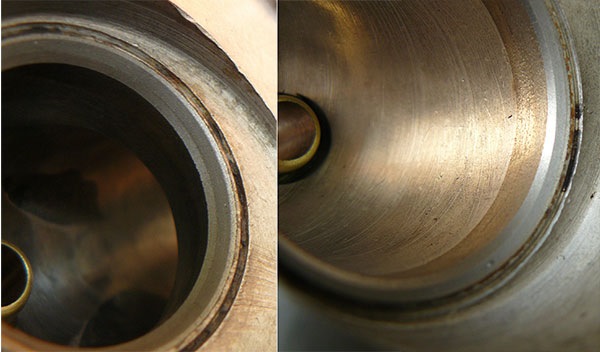

Yuri "Intervent" helped us with boring channels. Bored inlet by 33 mm, exhaust by 30 mm (28 mm seat):

He also bored the intake manifold with gasket and fitted them to the cylinder head channels. However, we will talk about this separately.

Before you give the cylinder head for subsequent grinding and cutting, you must first resolve the issue with the valve guide bushings (2101-1007033). Indeed, for cutting saddles, already pressed guides are needed, and in order not to carry the cylinder head twice, it is better to worry about them right away.

To choose bushings, let's first decide on their material:

1) Cast iron - ready-made stock guides from 2101 or variant from 2108 - manufactured by SM, AMP, AvtoVAZ.

2) Brass - finished guides manufactured by AvtoVAZ

3) Metal-ceramics - take ready-made bushings from ZMZ or foreign cars and grind them to fit the VAZ one;

4) Bronze - buy ready-made "cooperative" bushings (amag, etc.) or turn to order from your own bronze.

It is not difficult to guess that the options with bronze and cermet are the most interesting. Moreover, bronze is not inferior to cermets. Here is a quote from an article by Alexander Khrulev, the author famous book"Repair of engines of foreign cars":

"... guides made of bronze can be installed without any negative consequences instead of cermet guides, which are widely used on American and Japanese engines. At least after a run of 80-100 thousand km, no problems were noted with the engines repaired in this way."

It's decided - we put bronze guides! Where can you get them?

Buying ready-made bushings is a dangerous business. There is no guarantee that the manufacturer did not use cheaper material (especially expensive bronze bushings).

Yes, and in the manufacture of their bushings, you can always clearly observe the size for a specific cylinder head and specific valves. And yes, they can be shaped better.

Therefore, we chose the safest option - we bought the bronze ourselves and gave it to a trusted turner.

Which bronze to choose? Let's estimate according to the available evaluation information:

1) BrOS, BrOTsS - tin bronzes. Cheap and soft. You can use it, but it's not very desirable. Unless BrOTsS5-5-5 can be put on the inlet.

2) BrAZh-9-4 - aluminum bronze. Common working option. Average price, acceptable properties.

3) BrB2 - beryllium bronze. Perhaps the best option, but also the most expensive. We do not have a sports motor, so Brb2 is still too much for us.

4) BrKMTs3-1 - silicon-manganese bronze. It is considered by some to be the best alternative to beryllium bronze.

We opted for BrKMTs3-1. On this occasion, we again quote Khrulev:

"…In addition to BrB2, it is possible to use much cheaper and more accessible BrKMTs bronze for guide bushings. It is also a tried and tested option. By the way, this alloy was specially developed in our country for such purposes. Both of these bronzes can be used for bushings in both intake and exhaust valves, which are known to operate under different temperature and lubrication conditions. There were no obvious restrictions on the resource of parts made from them."

The weight of our rod turned out to be 1.306 kg, and the calculator showed that the density of the bronze we bought corresponds to the density of the BrKMTs bronze. They didn't cheat! :)

They decided to make the guides with streamlined shapes in order to less interfere with the movement of the fuel-air mixture in the channels:

Of course, the outlet sleeve is slightly longer.

If you are interested, after making the guides, we have such a piece of bronze left: :)

Now that we have dealt with the guides, we can deal with the head itself. We are taking the cylinder head of our "Ryzhik" for further mechanical processing. We have commissioned these works.

Was done:

1) milling the surface of the cylinder head by about 0.4 mm and grinding:

The photo shows already lapped saddles.

On the intake seat (on the right in the photo), the 30-degree external chamfer turned out to be smaller, because. valves are already squandered by about 0.5 mm. The width of the working 45-degree chamfer is about 1 mm.

3) Development of guides for our valves. We strictly observe the thermal gap: 2.5 weave inlet, 4.5 weave outlet.

They didn’t make oil grooves in the bushings - the guys from Paton assured that they were not needed with this bronze and gaps.

Everything seemed to work out great, but there was one complication with the valve guides. The fact is that the turner machined the retaining rings on the guides themselves, and the depth of pressing them into the cylinder head is different. Apparently, this is due to the peculiarities of casting the cylinder head itself.

- The valves taken out from directing plugs of a head of cylinders to wash out carefully and to clear of a deposit and varnish deposits. For temporary storage, insert the cleaned valves with rods into the holes of a special wooden stand. Also thoroughly rinse and clean the cylinder head of carbon and varnish deposits.

- Measure the valve stems and their guide bushings in several planes and sections to determine the degree of their wear. New parts have the following dimensions: exhaust valve stem diameter 7.925-7.937 mm, inlet valve stem diameter 7.955-7.967 mm, valve guide bore diameter 7.992-8.022 mm. If the valve stem wear exceeds 0.02 mm, the valve should be discarded. If the wear of the guide bushing exceeds 0.08 mm, the bushing must be replaced.

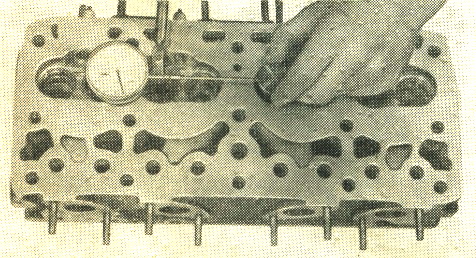

- Measure the diametral clearance between the valve stem and the guide sleeve by attaching an indicator to the cylinder head with a scale having a division value of 0.01 mm.

Rice. Main dimensions of valves and guide sleeve:

1 - valve guide sleeve; 2 - inlet valve; 3 - exhaust valve

Rice. Measuring the diametrical clearance between the valve stem and the valve guide

When measuring the clearance, the valve must be pulled out of the guide sleeve so that the end of its stem is flush with the end of the guide sleeve. When rocking the valve towards the indicator and back, the indicator will indicate the value of the diametrical clearance between the valve stem and the guide sleeve, increased by 2.8 times. The gap should not exceed 0.1 mm for the intake and 0.15 mm for the exhaust valve.

The value of the diametrical clearance is a criterion for deciding whether it is expedient to further use this valve and its bushing in the engine. In some cases, to achieve the above clearances or approach the clearances of a new engine, it may be necessary to replace the valve or guide sleeve, or replace both of these parts at the same time.

When repairing or forcing an engine, the issue of maintaining or increasing the resource of individual components and parts, on which the load increases during forcing, is acute.

One of the most problematic engine parts is the valve guide.

Serial bushings for eight-valve VAZ engines are made of special cast iron, which, unfortunately, is not highly resistant to wear. VAZ serial bushings suffer from poor geometry, and on many engines for a run of 30-40 thousand km, the valve play due to wear exceeds all reasonable tolerances, and when the engine is running, a characteristic valve knock is heard. The quality of the workmanship and the geometry of the heads for Oka engines is even worse, this is especially evident in the heads of the late 90s.

And only on the 2112 engine (16 valves) brass bushings (Ls65) are serially installed, which have a longer service life than cast iron ones.

How to replace unreliable cast-iron bushings? The answer was found a long time ago - special guide bushings made of bronze alloys. For guide bushings, not every bronze is suitable, but only a few grades, specially selected and tested in motorsport.

The advantages of bronze bushings are as follows:

Better heat dissipation from the valve stem and heat transfer to the aluminum head body, high wear resistance, excellent compatibility with steel and chrome valves, less demanding on the amount of oil that gets on the valve stems.

Cylinder head repair specialists also note important feature bronze bushings - the material is quite plastic, does not split like a cast-iron bushing, and therefore, the risk of splitting the bushing (cracking) when it is pressed in, or under extreme engine operating conditions, is reduced to zero.

For VAZ 2108\2110 engines, the production of bushings of two types has been mastered - for a valve stem with a diameter of 8 mm and for valves with a stem diameter of 7 mm. The second type of bushings for the 2108 engine family has a serial outer diameter, an inner diameter of 7 mm, and valve stem seals are used from the 16 valve engine 2112. A set of such bushings is shown in the photo below. These bushings are used for extreme tuning of the engine with 40x34 valves.

Bronze valve stems with 7mm stem

Bronze bushings 2108 are also used in Oka engines. In addition, it is permissible to use these bushings on engines of the VAZ "classic" family.

An economical option was also tested, when bronze bushings are used only on exhaust valves, and high-quality imported cast-iron guides are used for intake valves. Such a combination is justified not only by savings, but also by an increase in the total cylinder head resource during normal head repairs, because exhaust guide bushings are the most loaded.