Consists of a differential. How different types of differentials work.

Differential - a mechanism that distributes torque between the output shafts, and the speeds of individual elements may be different. This device is used in the construction of car drives. The torque received from the cardan shaft (or gearbox) is distributed between the left and right axle shafts. Also used to share the moment between the axes (leading), if we are talking about all-wheel drive vehicles.

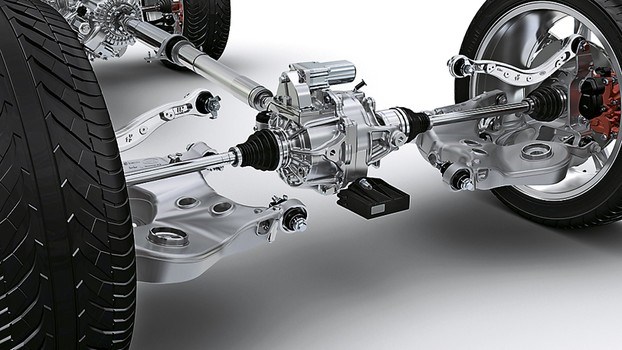

The differential is a very important component, and is one of the main elements of the transmission. The location of this device in the car:

- front-wheel drive cars - gearbox;

- rear-wheel drive cars - rear axle housing;

- all-wheel drive car - rear and front crankcase;

- all-wheel drive vehicle - transfer case (axle drive);

- in the case of vehicles with an 8 × 8 or 6 × 6 drive, additional inter-bogie differentials are installed;

We will provide information on the operation and types of center differentials below.

When it happens rectilinear motion on a flat road, the path traveled by the driving wheels will be equal (same angular speed). During this movement, the rotation of all planets, gears and differential housing is synchronous. The rotational moment is transmitted to this mechanism by a gear (5, Fig. b). It is also worth noting that during such a movement, the torque of each wheel is the same, and the gears (half-axle) are wedged by satellites (4), which are in a static state in relation to their axis.

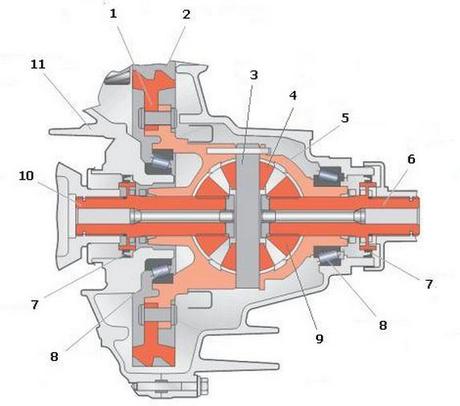

a - design;

b - work process (rectilinear movement);

c - workflow (rotation);

- bowl (case);

- side gear;

- cross;

- satellites;

- driven gear (main gear);

- drive shaft (main gear);

- axle shaft.

During the entry into a turn (Fig. "c"), the path traveled by the wheel going along the "inner" radius is smaller than that of the opposite wheel, which means that its speed should change. The side gear (2) should slow down, while the housing and satellites should rest against the side gear on the left. Due to the beginning of the rotation of the satellites around its own axis, the speed of rotation of the right semi-axial gear will increase, which allows the drive wheels to have different speeds of rotation, and at the same time to exclude slipping and slipping. It is worth noting that the wheel having a higher rotational speed has a lower torque.

If we consider the differential, which has a classic design, then the most important drawback is the slipping of one of the wheels at the moment of loss of contact with the road surface. The fact is that the speed of rotation of the wheel in the "suspended" state is almost twice the speed of rotation of the same wheel in full contact with the road (straight ahead) and an equal number of revolutions of the gear (driven) of the differential. The second wheel remains static. The reason is very small value the torque that is supplied to it, since during the rotation of the “suspended” wheel, the value of the moment of resistance to rotation is also quite small. Accordingly, the torque of the opposite wheel is also small, so it is in a static state. In the event that there is significant resistance during slippage and at higher speeds (mud, sand, etc.), the torque will be greater than in the slip situation, and therefore more torque is transferred to the other wheel. This makes it possible for the vehicle to move slowly. A wheel that is slipping “consumes” more power, which is spent on heating tires, the roadway, etc. In general, slipping reduces the patency of a car with a free differential. To eliminate such a problem, differential lock mechanisms on cars, which are both manual and automatic.

Basically, the car's transfer case is the installation site for the center differential mechanism. It is asymmetrical and symmetrical. In the first case, the distribution of torque occurs in the required ratio, and in the case of a symmetrical differential, the moment is distributed equally.

The center differential can be without a locking mechanism, so that the axles can rotate with different speeds. Differentials can also be with manual blocking and self-locking. In the first variant, the torque is forcibly distributed between the axle shafts. The result of forced blocking is a partial or complete shutdown of the differential, which causes a rigid connection of the rear and front axle shafts.

Basically, in order to fully realize the capabilities of all-wheel drive vehicles, self-locking differentials are used, which have several types of designs, each of which differs in the principle of operation.

> Differential

Transmission

Purpose, principle of operation of the differential

The differential is designed to transmit torque from main gear to the axle shafts and allows them to rotate at different speeds when turning the car and on uneven roads.

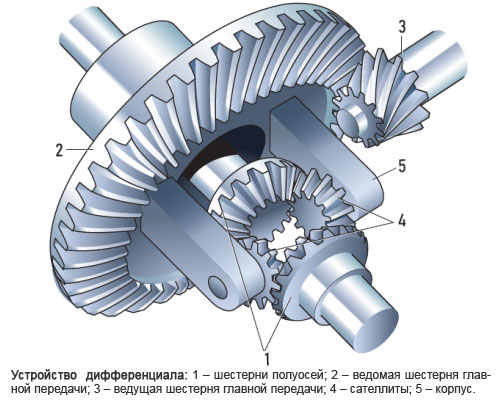

On cars, bevel gear differentials are used (Fig. a), which consist of semi-axial gears 3, satellites 4 and a housing uniting them, attached to the driven gear of the final drive.

a - the wheels rotate at the same frequency, b - the movement of the wheels on the turn

1 - axis of satellites, 2 - driven gear, 3 - side gears, 4 - satellite,

5 - drive gear, 6 - axle shafts.

Differentials of this type are used between the wheels of the drive axles as interwheel. For different cars, they differ in the design of the body and the number of satellites. Bevel differentials are also used as center differentials. In this case, they distribute the torque between the final drives of the drive axles.

For simplicity, the figure does not show the differential case, therefore, for consideration of the principle of operation, we will assume that the axis 1 of the satellites is installed in the case. When the drive gear 5 and the driven gear 2 of the main gear rotate, the torque is transmitted to the axis 1 of the satellites, then through the satellites 4 to the side gears 3 and to the axle shaft 6.

When driving in a straight line and flat road rear wheels meet the same resistance and rotate with the same frequency (Fig. a). The satellites do not rotate around their axis and the same torque is transmitted to both wheels. As soon as the driving conditions change, for example, on a turn (Fig. b), the left axle shaft begins to rotate more slowly, since the wheel with which it is connected encounters a lot of resistance. The satellites come into rotation around their axis, running around on the slowing down semi-axial gear (left) and increasing the speed of the right semi-axis. As a result, the right wheel accelerates its rotation and goes a long way along the arc of the outer radius.

Simultaneously with the change in the speeds of the side gears, the torque on the wheels changes - the torque drops on the accelerating wheel. Since the differential distributes the torques to the wheels equally, in this case, a decrease in torque also occurs on the decelerating wheel. As a result, the total moment on the wheels drops and the traction properties of the car are reduced. This has a negative effect on the vehicle's patency when driving off-road and slippery roads, i.e. one of the wheels stands still (for example, in a pit), while the other is slipping at this time (on damp earth, clay, snow). But on well-grip roads, the bevel gear differential provides better stability and control, and the driver doesn't have to change worn out tires every day.

1 - flange; 2 - drive gear shaft; 3 - drive gear; 4 - driven gear;

5 - driving (rear) wheels; 6 - axle shafts; 7 - main gear housing.

Types of differentials.

To increase the vehicle's cross-country ability when driving off-road, differentials with forced locking or a self-locking differential are used.

The essence of forced locking is that the leading element (case) of the differential at the moment the lock is turned on is rigidly connected to the side gear. For this, a special remote device with a gear clutch is provided.

Self-locking limited slip differential (cam), shown in fig. a, b. It consists of inner 5 and outer 6 sprockets, between the cams of which crackers 3 of the separator 4 are laid. The separator is made in one piece with the left differential cup and is connected to the final drive driven gear. The right cup (not shown in the drawing) freely covers the outer sprocket and, together with the left cup, forms the differential housing. The sprockets of the differential with their internal splines are connected to the axle shafts 1.

When the driven gear of the main gear rotates and the car moves in a straight line, the crackers exert the same pressure on the cams of both sprockets and make them rotate at the same speed.

If one of the wheels hits the road surface with high resistance to movement, then the sprocket associated with it starts to rotate at a lower frequency than the cage. Crackers, being in the separator, exert more pressure on the cams of the slowing sprocket and accelerate its rotation.

Thus, at the points of contact of the crackers with the cams of the stars, increased friction occurs, which prevents a strong change in the relative speeds of both sprockets, and the wheels rotate at approximately the same angular speed. Due to the forces of friction of crackers on the cams, a redistribution of moments occurs. On the accelerating sprocket, the friction forces are directed against rotation, on the lagging sprocket - in the direction of rotation. The torque on the lagging sprocket increases, and on the accelerating sprocket it decreases by the moment of friction forces, as a result, wheel slip is excluded.

The main malfunctions of the main gear and differential

Noise (“howl” of the main gear) when driving at high speed occurs due to wear of the gears, their incorrect adjustment, or in the absence of oil in the main gear housing. To eliminate the malfunction, it is necessary to adjust the gear engagement, replace worn parts, and restore the oil level.

Oil leakage can be through seals and loose connections. To eliminate the malfunction, replace the seals, tighten the fasteners.

Main gear and differential operation.

Like any gears, the final drive and differential gears require “lubrication and caress”. Concerning "kindness". Although all the details of the main gear and differential look like massive pieces of iron, they also have a margin of safety. Therefore, recommendations regarding abrupt starts and braking, rough clutch engagement and other overload of the machine remain in force. Friction parts and gear teeth, including, must be constantly lubricated - we already know this. Therefore, oil is poured into the crankcase of the rear axle (for rear-wheel drive cars) or into the crankcase of the block - gearbox, main gear, differential (for front-wheel drive cars), the level of which must be periodically monitored. The oil in which the gears operate tends to "leak" through leaks in the joints and through worn oil-retaining seals. And yet, any crankcase must have a constant connection with the atmosphere. When heat is generated in a tightly closed box with gears and oil, which is inevitable during the operation of mechanisms, the pressure inside increases sharply and then the oil will definitely find some kind of hole. In order not to add oil twice a day, you should be aware of a small part of any crankcase - a breather. This is a spring-loaded cap that covers the vent or tube. Over time, it "sticks" and the crankcase may lose connection with the atmosphere. At the next scheduled oil change or earlier, if necessary, turn the caps and restore the springs of all breathers on the units of your car. As a result of this simple operation, small oil leaks can stop.

It is usually difficult for the average driver to understand the range of sounds that his “sick” car makes. Not enough to possess good hearing, you also need to understand what these “howls”, “crunches” and other “creaks” coming from certain areas of the car mean. However, you can narrow the troubleshooting area a bit. If you suspect any trouble with the transmission, jack up one of the driving wheels of the car (and be sure to lower it onto the "goat" - a stable stand). Start the engine and, by engaging the gear, make this wheel rotate. Look at everything that is spinning, listen to everything that makes suspicious sounds. Then jack up the wheel on the other side. With increased noise, vibrations and oil leaks - start looking for your master, to whom you can proudly tell that your car has problems on the left, not on the right.

Many who were going to buy an SUV, when choosing a certain model, of course, could come across the term “differential lock”. But what is it? Like this? And what is the principle of operation and the need for this very differential? As practice shows, not all future potential "jeep drivers" know.

In this article, we will talk about what is a differential And why is he in the car. What varieties does it come in and on which cars is it intended to be installed?

History of the differential

![]() The appearance of the differential in the automotive world was not long in coming. Only a few years later, after the first cars with an internal combustion engine (ICE) began to roll off the assembly line. For a long time, things were not as sweet as they are now, and the first automobile samples that worked with the help of an engine were very poorly controlled.

The appearance of the differential in the automotive world was not long in coming. Only a few years later, after the first cars with an internal combustion engine (ICE) began to roll off the assembly line. For a long time, things were not as sweet as they are now, and the first automobile samples that worked with the help of an engine were very poorly controlled.

Wheels located on the same axis rotated at the same angular speed during the turn, and this already led to the fact that the wheel running along the outer diameter was slipping heavily. We solved this problem quite simply: by borrowing the differential from steam carts.

This mechanism was invented in France in 1828 engineer Oliver Pekke-Rom. It was a device that consisted of shafts and gears. Through it, the torque from the internal combustion engine was transmitted to the drive wheels. But another bad luck happened - the wheels began to slip, which lost traction with the road surface. Often this manifested itself while driving on a road with icy areas.

The wheel, which was on the ice, rotated at a higher speed than the wheel, which remained on a surface more suitable for movement. This led to a skid. After the designers began to think about how to adjust the differential so that the wheels rotate at the same speed in order to prevent the appearance of drifts.

The first person to experiment on a differential with minimal slip was none other than Ferdinand Porsche. It took at least three years. They were equipped with the first models of cars of the brand. In the following decades, engineers developed various types of differentials, which we will tell you about next.

Principle of operation and device

Let's perhaps start with the type of differential that is the easiest to consider, the open differential. We'll start with the simplest type of differential, called an open differential. So, The design of the differential includes the following parts:

- Drive shaft. Its task is to transmit torque. The shaft leads it from the transmission to the very beginning of the differential.

- Drive shaft drive gear. Gear in the form of a helical cone, necessary for coupling differential mechanisms.

- Ring gear. An element that is driven. It also has the shape of a cone and is rotated by a drive gear. The system of the driving and driven gears together is called the final drive. It serves as the final step in reducing the speed of rotation that eventually reaches the wheels. The drive gear is much smaller in size than the crown gear., therefore, to carry out one revolution of the slave, the first one needs to make more than one revolution around its axis.

- Half shaft gears. Are last frontier transmission of rotation of the drive shaft to the wheels.

- Satellites- This is a planetary mechanism that plays a key role in providing different angular speeds of the wheels when turning.

![]() When you move in a straight line on your car, the entire differential mechanism rotates at the same speed: the input shaft rotates at the same speed as the axle shafts, respectively, the wheels themselves rotate at the same speed. But as soon as you turn the steering wheel, the situation instantly changes radically. The main players now satellites protrude, which are unlocked under the influence of the difference in loads on the wheels when, for example, one wheel starts to slip and therefore moves faster.

When you move in a straight line on your car, the entire differential mechanism rotates at the same speed: the input shaft rotates at the same speed as the axle shafts, respectively, the wheels themselves rotate at the same speed. But as soon as you turn the steering wheel, the situation instantly changes radically. The main players now satellites protrude, which are unlocked under the influence of the difference in loads on the wheels when, for example, one wheel starts to slip and therefore moves faster.

All the power of the motor passes directly through them. And as a result of the fact that the satellites are two gears that are independent, then there is a transfer of different speeds of rotation to two semi-axes. But the power is not divided equally, and is transmitted to the wheel that is moving at the outer edge of the car's turn. Consequently, it begins to spin much faster due to the quantitative addition of revolutions. And the difference in the distribution of power between the wheels is the greater, the smaller the turning radius of the car, that is, the more you turn the steering wheel.

What is a differential lock and how does it work?

Differential lock- this is one of most effective ways improve the off-road performance of the car. Any car that is intended directly or indirectly for off-road is equipped with a mechanism at the factory that locks the center differential. Also, cars are equipped with mechanisms that block the front and rear axles.

The blocking of this mechanism, like any technological solution, has its advantages and disadvantages. To understand when it is necessary to use differential locks, and which cases simply prohibit its use, you need to understand the principles on which its operation is based.

Try to make a long jump from a place in the winter snowy time. Yeah. But it doesn’t work, and all because one of your feet was on a slippery icy surface, and the other on dry pavement. Because of this, it was not possible to make a championship jump. One leg slipped out from under you, and the brain did not orient itself in time and did not give the command to put all the force to push into the other leg. The result of this experiment is quite funny and comical: your legs parted and you almost collapsed on the fifth point.

So what to do in this case, so that both legs have the opportunity to perfectly push off the ground? And everything is very, very simple. You just need to turn two pushing legs into one, tying them firmly together with a strong belt or harness. Now they will work as one unit and will use the maximum push force from one stable ground with good grip. A similar process occurs in the car at the moment of interaction of its driving wheels with the road.

Let's imagine a situation in which a rear wheel drive car stops randomly so that its left wheel is on a slippery surface and its right wheel is on asphalt. As you know, standard low friction center differential, which is located on rear axle vehicle, always provides the wheels with equal circumferential force. The left wheel, which is on ice, is not able to move from a slippery surface with great effort due to lack of traction.

Let's imagine a situation in which a rear wheel drive car stops randomly so that its left wheel is on a slippery surface and its right wheel is on asphalt. As you know, standard low friction center differential, which is located on rear axle vehicle, always provides the wheels with equal circumferential force. The left wheel, which is on ice, is not able to move from a slippery surface with great effort due to lack of traction.

And because of this, the differential is not able to provide him with a huge effort, since this is simply impossible physically. And in this case a similar force will be applied to the wheel which is located on the asphalt surface. It will even out the forces that are distributed between the wheels, focusing on the left wheel.

As a result, the car will move with slipping, but slowly. His wheels will not be able to use enough force to push, which would be necessary for the adhesion of the right wheel, which under the given conditions will be neither more nor less, but as much as seven times greater than that of the left. Due to this property of distributing tractive force equally, the right wheel will only use a seventh of its traction capacity. To put it simply, the push could have been seven times stronger, but the differential didn't apply enough force to it to make the maneuver.

Therefore, it is necessary to implement such a connection between the wheels to ensure joint rotation or slipping, as if it were a single wheel. To solve this problem, a special mechanism is used that blocks the rotation of the differential gears and connects the two wheels to each other by a conditional rigid connection with constant rotation and the same speed. Such a mechanism is called a "differential locking (disconnecting) mechanism", or in the common people - a lock.

A differential that is locked is not able to equalize the inter-wheel force, thereby making them connected by a single axle. As a result, each wheel receives the maximum possible force, which is necessary for the best grip of the wheels. Therefore, where the grip of the wheels with the road surface is better, more force will be applied there.

What are the differentials

The basis of the differential is a planetary gearbox. The type of gear that is used can conditionally divide the differential into three type:

- Worm;

Cylindrical;

Conical.

The worm differential is the most versatile and is installed both between the axles and between the wheels. The cylindrical type is often located in SUVs between the axles. The conical type is mainly used as a cross-axle differential.

Allocate the same symmetric And asymmetrical differentials. The asymmetric differential design is installed in all-wheel drive vehicles between the axles, distributing torque in various proportions. The symmetrical type transmits equal torque to the axle between the two wheels. Differentials are also divided according to the type of blocking:manual lock and electronic lock.

Manual differential lock

Based on the name, the axle differential lock is activated at the initiative of the driver by pressing a button or switching a certain toggle switch. In this case, the satellite gears are blocked, as a result of which the drive wheels begin to rotate at the same speed. Often, SUVs are equipped with a manual differential lock. It is recommended to turn it on to overcome difficult off-road conditions, and turn it off when entering a regular asphalt road.

Electronic or automatic differential lock

Automatic differential locking is carried out by commands of the electronic control unit, which analyzes the state in which the road surface is located, using ABS and ESP. The ECU then blocks the satellite gears on its own. According to the degree of blocking, this device can be conditionally divided into a differential with full and partial blocking.

Full differential lock

The inclusion of such a lock implies the fact that the satellite gears stop completely, and the mechanism takes on the functions of a conventional clutch, thereby transmitting an equal torque to the two axle shafts. As a result, both wheels rotate at the same angular speed. If it happens that at least one wheel loses grip, then the torque from it is fully transferred to the other wheel, which remains to force off-road. Such a differential device has been successfully implemented on Toyota Land Cruiser, Mercedes-Benz G-Class and others.

Partial differential lock

Engaging this lock does not completely stop the satellite gears, but allows them to slip. This effect is available thanks to self-locking differentials. Depending on the type of operation of this mechanism, it is divided into two kinds: Speed sensitive(activated when a difference in the angular speeds of rotation of the semiaxes is noticed) and Torque sensitive(activated in case of a decrease in the torque of one axle shaft). This type of operation of the differential device can be found on SUVs Mitsubishi Pajero, Audi Q-series and BMW X-series.

Differential group Speed sensitive differs in structure. One such mechanism is one in which differential function performs viscous coupling. The viscous coupling differs from the friction differential in its lower reliability. It is because of this that it has a place to be installed on cars that are not designed to overcome impassable wilds and deep fords or on cars with a sporty character.

Differential group Speed sensitive differs in structure. One such mechanism is one in which differential function performs viscous coupling. The viscous coupling differs from the friction differential in its lower reliability. It is because of this that it has a place to be installed on cars that are not designed to overcome impassable wilds and deep fords or on cars with a sporty character.

Another mechanism representing the Speed sensitive group is called the gerotor differential. The role of blocking elements here is played by an oil pump and friction plates mounted between the differential housing and the satellite gears of the axle shafts. Although according to the principle of operation, it is similar to a viscous coupling.

Differentials that belong to the group Torque sensitive are also different in their design. For example, there is a mechanism using a friction differential. Its peculiarity lies in the difference in the angular velocities of the wheels in turns and when moving in a straight line. When the car is moving in a straight line, the angular speed of rotation of both wheels is the same, and during cornering, the torque for the wheels is different.

Another type of differentials - with hypoid and helical gearing. They are subdivided into three groups.

First – with hypoid gear

Here, each axle shaft has its own satellite gears. They are attached to each other by spur gearing, located perpendicular to each other. In the event of a difference in the angular velocities of the driving wheels, the gears of the semi-axes are wedged. As a result, the gears rub against the differential housing. The differential is partially blocked and the torque is redistributed to the axle, with a lower speed of angular rotation. After equalizing the semi-axial speeds, the blocking is deactivated.

Second – with helical gearing

Second – with helical gearing

Similar to the first, but the location of the satellite gears is parallel to the axle shafts. These units are attached to each other by helical gearing. The satellites of this mechanism are mounted in special niches on the differential housing. When there is a difference in the angular speed of the wheel rotation, the gears wedged and mate with the gears that are in the niches of the differential housing. There is a partial blockage. The direction of the torque is determined on the axis with a lower rotational speed.

Third – with helical gears of semiaxes and helical gears of satellites

Used in center differentials. The principle is the same - shifting torque to an axle with less rotation. The displacement range of this species is quite large - from 65/35 to 35/65. When the angular speed of the wheel rotation of both axles is stabilized and equalized, the differential is unlocked. These differential groups are widely used in the automotive industry on both conventional and sports models.

Advantages and disadvantages of differential locks

+ the possibility of wheel blocking up to 70%;

Minimum maintenance;

No jerks on the steering wheel;

The gearbox does not require pouring special oil;

Installation does not entail any difficulties;

Ensuring the best off-road vehicle performance;

Longer life of the structure;

Better car handling;

Ability to corner at higher speeds;

The car is easier to get out of a skid.

Over time, the preload drops;

It is required to replace the adjusting elements every 40 thousand kilometers for better design performance;

Not timely or late adjustment work will lead to the fact that the system will not work correctly.

Subscribe to our feeds

When choosing an SUV, many buyers must have come across the term “electronic differential lock” in the description of a particular model. But what it is, and how this very differential works, not all potential owners of cars of this class know. In our today's material, we will tell you in detail what a differential is for, what its varieties are and on which cars it is installed.

History of creation and purpose of the differential

On cars equipped with an internal combustion engine, the differential appeared a few years after their invention. The fact is that the first copies of machines powered by an engine had very poor handling. Both wheels on the same axle rotated at the same angular speed during the turn, which led to the slip of the wheel moving along the outer, larger than the inner diameter. The solution to the problem was found simply: the designers of the first cars with internal combustion engines borrowed a differential from steam carts - a mechanism invented in 1828 by French engineer Oliver Pecke-Rom. It was a device consisting of shafts and gears through which the torque from the engine is transmitted to the drive wheels. But after installing a differential on the car, another problem was discovered - wheel slip, which had lost traction.

This usually manifested itself when the car was moving on a road covered with patches of ice. Then the wheel that hit the ice began to rotate at a higher speed than the one that was on the ground or concrete, which eventually led to the car skidding. Then the designers thought about improving the differential so that under similar conditions both wheels rotate at the same speed and the car does not skid. The first to experiment with the creation of a limited slip differential was Ferdinand Porsche.

It took him three years to develop, test and market the so-called cam differential, the first limited-slip mechanism that was installed on the first models of the Volkswagen brand. Subsequently, engineers developed different kinds differentials, which will be discussed below.

In a car, the differential performs three functions: 1) transmits from the engine to the drive wheels, 2) sets the wheels to different angular speeds, 3) serves in combination with the final drive.

Differential device

The differential, improved by automotive designers, is arranged in the form of a planetary gear, where the torque from the engine is transmitted through the cardan shaft and bevel gear to the differential housing. That, in turn, directs the torque to two gears, and they already distribute the moment between the axle shafts. The clutch between the satellite gears and the axle shafts has two degrees of freedom, which allows them to rotate at different angular speeds.

Thus, the differential provides a different speed of rotation of the wheels located on the same axle, which also prevents slipping when turning. After it was invented, the car had two, and later three (with center) differentials, which distributed torque between the drive axles.

It is already clear that not a single car can do without a differential. In front- and rear-wheel drive vehicles, it is located on the drive axle. If the car has a dual drive axle, then two differentials are used in the transmission design - one for each axle. There are two differentials in all-wheel drive vehicles (for models with plug-in all-wheel drive- one for each axle) or three (for models with permanent all-wheel drive - one for each axle, plus a center differential that distributes torque between the axles). In addition to the number of mechanisms installed on cars with different types of drives, differentials are distinguished by the type of lock.

Varieties of differentials

According to the type of blocking, differentials are divided into two - manual and electronic blocking. Manual, as the name implies, is done manually by the driver using a button or toggle switch. In this case, the satellite gears of the mechanism are blocked, the drive wheels move at the same speed. Typically, a manual differential lock is provided on SUVs.

Electronic or automatic differential lock is carried out using an electronic control unit, which, analyzing the condition of the road surface (using information from sensors and traction control), blocks the satellite gears itself.

Range Rover Sport Electronically Controlled Rear Differential

Range Rover Sport Electronically Controlled Rear Differential

According to the degree of blocking, this device is divided into a differential with full blocking and a differential with partial blocking of satellite gears.

Full differential lock implies a 100% stop of the rotation of the satellite gears, at which the mechanism itself begins to perform the function of a conventional clutch, transmitting an equivalent torque to both axle shafts. As a result, both wheels rotate at the same angular speed. If one of the wheels loses traction, all the torque is transferred to the wheel with better grip, which will allow you to overcome impassability. Such a differential device is used on SUVs, and others.

Partial differential lock involves an incomplete stop of the rotation of the satellite gears, that is, with slipping. This effect is achieved due to the so-called self-locking differentials. Depending on how this mechanism works, they are divided into two types: Speed sensitive (function with a difference in the angular speeds of rotation of the semi-axes) and Torque sensitive (function with a decrease in torque on one of the semi-axes). Such a differential device is used on SUVs Mitsubishi Pajero, Audi with, BMW with X-Drive system and so on.

Differentials belonging to the Speed sensitive group have a different design. There is a mechanism in which the viscous coupling plays the role of a differential. It is a reservoir located between the axle shaft and the propeller shaft rotor, filled with a special viscous liquid, into which, in turn, the disks articulated with the axle shaft and the rotor are immersed. When the angular speed of rotation of the wheels differs (one wheel rotates faster than the other), the disks in the tank also begin to rotate at different speeds, but the viscous fluid gradually equalizes their speed, and, accordingly, the torque. As soon as the angular speeds of both wheels are equal, the viscous coupling is turned off. According to its characteristics, a viscous coupling is less reliable than a friction differential, therefore it is installed on vehicles designed to overcome medium-degree off-road or sports car modifications.

Another differential mechanism belonging to the Speed sensitive group is the gerotor differential. Here, the role of the lock, unlike the viscous coupling, is played by the oil pump and friction plates, which are mounted between the differential housing and the satellite gear of the axle shafts. But the principle of operation is in many ways similar to that of a viscous coupling: when a difference occurs in the angular speeds of the drive wheels, the pump pumps oil onto the friction plates, which, under pressure, block the differential housing and the axle gear until the wheel speeds are equal. As soon as this happens, the pump stops working and the blockage is disabled.

Differentials belonging to the Torque sensitive group also have a different design. For example, there is a mechanism that uses a friction differential. Its feature is the difference in the angular speeds of rotation of the wheels when the car is moving in a straight line and in a turn. When driving on a straight road, the angular velocity of both wheels is the same, and when cornering, its value is different for each wheel. This is achieved by installing a friction clutch between the differential housing and the satellite gear, which helps to improve the transmission of torque to the wheel that has lost traction.

Another type of differentials is with hypoid (worm or screw) and helical gearing. They are conditionally divided into three groups.

The first is with hypoid gearing, in which each axle shaft has its own satellite gears. They are combined with each other by means of spur gearing, and the gear axis is perpendicular to the semi-axis. If there is a difference in the angular speeds of the driving wheels, the gears of the semi-axes are wedged, friction is formed between the differential housing and the gears. There is a partial blocking of the differential and the torque is transmitted to the axle, the angular velocity of which is less. As soon as the angular speeds of the wheels align, the lock is deactivated.

The second is with helical gearing, in which each axle shaft also has its own satellite gears (they are helical), but their axes are parallel to the axle shafts. And these units are combined with each other with the help of helical gearing. The satellites in this mechanism are installed in special niches on the differential housing. When the angular speed of rotation of the wheels differs, the gears wedging occurs, and they, mating with the gears in the niches of the differential housing, partially block it. In this case, the torque is directed to the axle shaft, the rotation speed of which is lower.

The third - with helical gears of the axle shafts and helical gears of satellites, which are parallel to each other. This type is used in the design of the center differential. Thanks to the planetary design of the differential, it is possible, by means of partial blocking, to shift the torque to that axle, the angular speed of rotation of the wheels of which is lower. The range of such a shift is very wide - from 65/35 to 35/65. When an equivalent angular speed of rotation of the wheels of the front and rear axles is established, the differential is unlocked.

These groups of differentials have been widely used in the automotive industry: they are installed both on “civilian” models and on sports ones.

Its main purpose is to distribute, change and transmit torque, and if necessary, to ensure the rotation of two consumers with different angular velocities.

Axle differential is a differential designed to drive the drive wheels, but if it is installed between the drive axles in an all-wheel drive vehicle - the center interval.

As a rule, the differential of the car is located in the following places:

- Driving axles in an all-wheel drive vehicle - in the transfer case

- Driving wheel drive in an all-wheel drive vehicle - in the crankcase of the rear and front axle

- Driving wheel drive in a front-wheel drive vehicle - in the gearbox

- Drive wheels in a rear-wheel drive vehicle - rear axle housing

The differential is based on a planetary gearbox. The type of gear used in the gearbox conditionally divides the differential into the following three types:

- Worm

- Cylindrical

- Conical

Worm gear is the most versatile differential and can be installed both between axles and between wheels. The cylindrical type, as a rule, is located in cars between the axles. The conical type is mainly used as an interwheel.

There are also asymmetrical and symmetrical differentials of the car. The asymmetric type is installed between two drive axles and allows the transmission of torque in various proportions. The symmetrical type, as a rule, is installed on the main gears and allows the torque to be transmitted to two wheels of equal value.

Automobile differential device

The main elements of the differential are:

- Side gears

- Pinion gears

- Frame

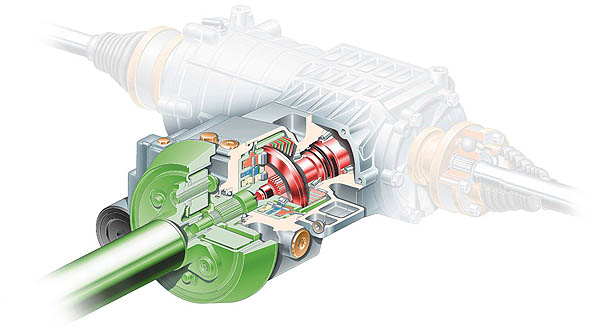

Diagram of a front-wheel drive car differential:

1 - driven gear of the main gear; 2 - a fragment of the main gear; 3 - axis of the satellites; 4 - satellite; 5 - differential case; 6 - right flanged shaft; 7 - stuffing box; 8 - tapered roller bearing; 9 - side gear; 10 - left flanged shaft; 11 - a fragment of the gearbox housing.

Satellite gears, in their principle of operation, resemble a planetary gearbox and serve to connect the housing and side gear to each other. The latter, in turn, are connected by splines to the drive wheels. Various designs use four or two satellites, in cars the second option is more commonly used.

Differential cup or housing - its main purpose is to transmit torque from the main gear to the side gears through the satellites. Inside it are the axis for the rotation of the satellite.

Sun gears or semi-axial gears - designed to transmit torque with the help of semi-axes to the drive wheels. The left and right gears can have either the same or different number of teeth. In turn, the gears different number teeth are used to form an asymmetrical differential, and with the same number - for a symmetrical one.

The principle of operation of an automobile differential

The differential works as follows: by rotating one of the driving wheels of the car, the second one will start to rotate in the opposite direction, but the condition of the cardan shaft immobility must be met. In this case, the stellites rotate in their own axes, playing the role of a gear.

If you start the engine and engage the clutch and any of the gears, the cardan shaft will begin to rotate, transmitting its torque through the spur and bevel gears of the differential box.

Thus, while the car is moving along a curved trajectory, one wheel slows down, while the second, on the contrary, increases it. As a result, slipping and slipping of the wheels are eliminated and each of them rotates at the speed that is necessary for safe movement.

When the car is moving in a straight line, nothing much happens and the differential transmits torque to both wheels in the same ratio. The semi-axial gears rotate with the same angular velocity, since the satellites in this case are in a stationary state.

When driving on slippery surfaces, the differential has one significant drawback - it can cause a side skid of the car, since the slipping wheel has low adhesion to the surface and it starts to rotate at idle.

The simplest car differentials have another drawback. When dirt or other third-party elements get between the splines, the torque can be transmitted in a different ratio, even 0 to 100. Thus, one wheel will remain in a completely static position.

Modern models are practically devoid of this drawback. Their device is different manual or automatic more rigid. Moreover, in many modern passenger cars, stabilization and directional stability systems are installed, which make it possible to optimize the distribution of torque depending on the trajectory of the car.

How the differential works - video: