Classic gearbox. Detailed description of the four types of checkpoints

Consider below all the concepts of gearboxes, their main pros and cons, prospects.

There are main types of gearboxes:

mechanical box manually controlled, this is an older type, but it has proven itself very well, especially among drivers who like to feel the full power of their iron horse. The natural disadvantage of such checkpoint low efficiency, due to the friction of the gear teeth, the resistance of the transmission oil.

automatic box, is also known and used for a long time in the automotive industry. Switching speed steps occurs automatically, but the command to start moving or reversing requires a driver's command. Like the manual transmission, the "machine" has a low efficiency for the same reasons and due to the presence of a box in the device.

Lovers of such boxes are, of course, our ladies. Many simply do not know that there used to be a third pedal - the clutch. The “American consumer” can also be attributed to the ladies, Americans very rarely buy cars with mechanics.

As mentioned above, manual transmission is the best option for a box, and even robotic box gear is made on its basis, but with automatic control. Control "robot" can even adapt to driving style. The disadvantages are the same as those of the mechanics, but there are much more pluses. By using two shafts, it was possible to increase the efficiency, reduce the overall dimensions, and increase the reliability of the box.

Motorists liked the robotic box, and for lovers of mechanics or just principled opponents of manual transmission, there is the possibility of switching to manual control mode.

The variator is a new word in gearboxes. The main disadvantage of the variator is still the impossibility of using it on heavier car models than small cars. An indisputable advantage is, of course, simplicity, a smooth change in torque, a fairly high efficiency, since there are no pairs of gears, except for “reverse”.

Motorists were divided almost equally into skeptics and fans of CVTs, but the times of manual transmission are gradually becoming a thing of the past and, for now, the future belongs to the “robot” and the CVT! And we'll live there - we'll see!

- this is the housing (crankcase), inside which there are gears. Clutch assembly between engine and transmission. They pressed the clutch pedal - the engine and gearbox were completely separated. As long as you keep the clutch pedal depressed, power unit and the gearbox are not connected in any way and you can select any gear based on the driving conditions.

Every transmission- these are two gears, a large one and a smaller one. If the small one is rotated by the engine, and the large one transmits rotation to the wheels, then we increase the moment (force), but decrease the speed. The larger the first wheel and the smaller the second, the lower the torque and the greater the speed. If more wheel from the side of the engine and less than that from the side of the wheels, we increase the speed, losing strength.

Detailed description of the four types of checkpoints.

By switching with the gear lever, we just choose through which pair of gears the rotation will be transmitted from the engine to the wheels. First gear is the most torque on the wheels and the smallest speed. Top gear - low torque and high speed.

neutral- this is when rotation is not transmitted through any of the pairs. Maintenance of "mechanics" is reduced to a scheduled oil change small volume, and the resource, with proper operation, approaches the resource of the car itself. But, unlike automatic box, in addition to the gearbox, we get a clutch assembly that has a certain resource and, accordingly, requires repair when the resource is exhausted.

The cost of repairing a manual transmission clutch assembly in individual cases can be comparable to the cost of repairing a manual transmission.

Detailed description four types of checkpoints

5 (100%) voted 1Modern automotive industry pleases motorists with the emergence of new technologies, interesting changes and significant improvements. However, despite this, the gearbox is one of the main components of the car. In this article, we will analyze the design of modern transmissions, consider the most common types of gearboxes and try to understand which one is better to choose in a given situation.

To date, there are several of the most common checkpoints:

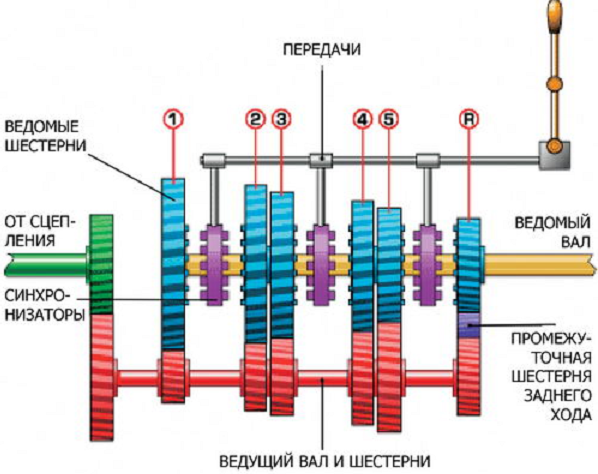

Manual transmission device and principle of operation of mechanics

Manual transmission consists of clutches, synchronizers, gears and shafts. The engine and gearbox are connected by a clutch assembly. To disengage them, depress the clutch pedal. It is at this moment that the required transmission should be included.

When choosing a gear, a competent driver is guided by the current traffic situation and the speed of the car. This is quite convenient for those who prefer an active, agile ride - for sharp acceleration, it is possible to shift to a lower gear.

However, there is one significant drawback. Just imagine, you are in the city center, rush hour, you get into another traffic jam and you have to pull the gearshift lever all the time.

Key design advantages of manual transmission:

It is interesting that “mechanics” are also provided in the device of cars for rally and road racing, however, instead of a shift lever, special buttons on the steering column are used - paddles on the steering wheel, which can significantly reduce the duration of gear changes.

To achieve maximum smoothness of the movement of a car with a manual transmission, experience is needed. In addition, each car has its own characteristics of the clutch and PP, which you need to get used to.

Automatic transmission device and principle of operation of the machine

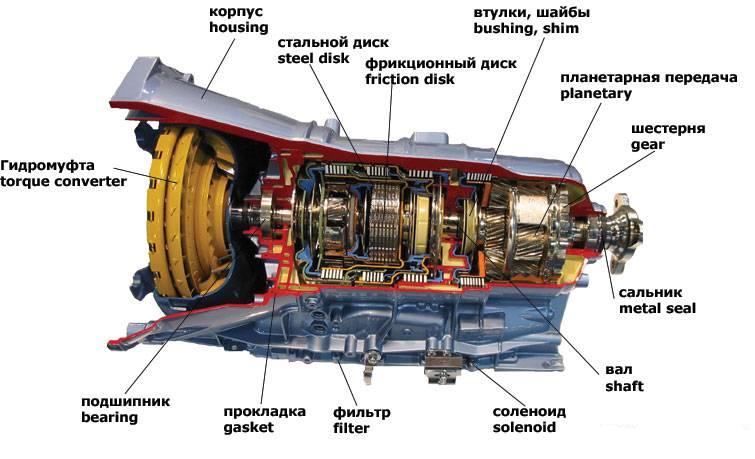

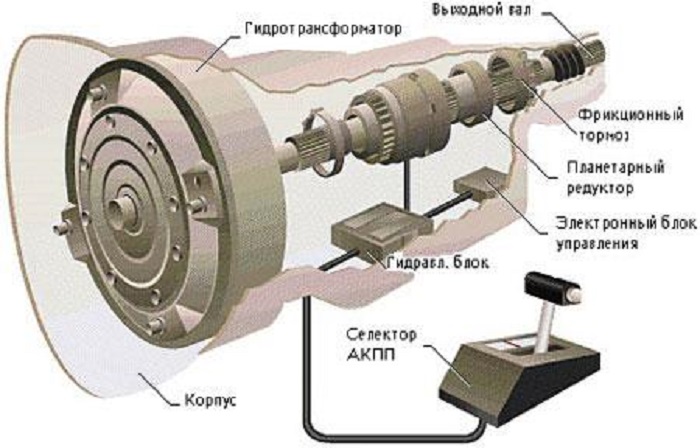

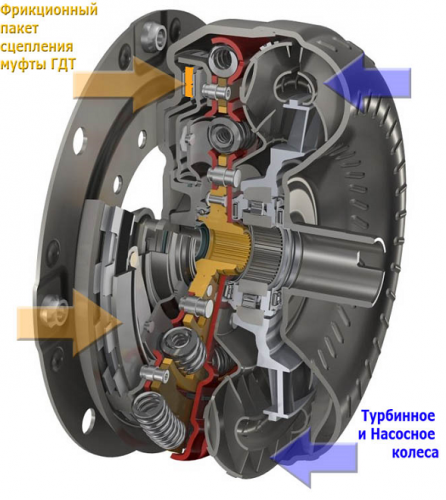

I propose to consider a classic three-speed automatic transmission, which consists of hydraulic drives and a torque converter. She, like "mechanics", accepts and converts torque. Its design consists of a hydraulic control system, a planetary gearbox and a torque converter.

Imagine a fan and an ordinary children's toy with a propeller. If you bring this toy to the turned on fan, the propeller will also start spinning. IN automatic transmission The screw does not drive the fan, but the motor of the car.

The second screw is connected to the shaft, which interacts with a key structure consisting of clutches, gears, and so on. The screws are located in a hermetically sealed housing with a special fluid - a torque converter.

The classic automatic transmission makes it possible to do without pressing the clutch pedal, which is quite convenient, especially for those who constantly drive the streets of a metropolis with very heavy traffic. At the right moment, the driver presses the brake or accelerator pedal. Among the shortcomings of the automatic transmission, it should be noted the increased fuel consumption and tangible gear shifting.

All transmission models have their weaknesses, but an automatic transmission on an old car can be a real headache. And this applies not only to weak points design, but also to the quality of service. A simple lack of oil can lead to premature wear. Solenoids, friction clutches often burn out, the torque converter fails.

Other disadvantages of classic automatic transmissions:

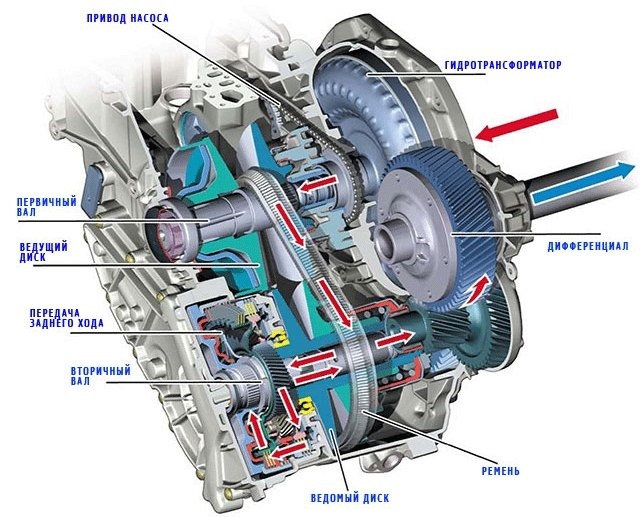

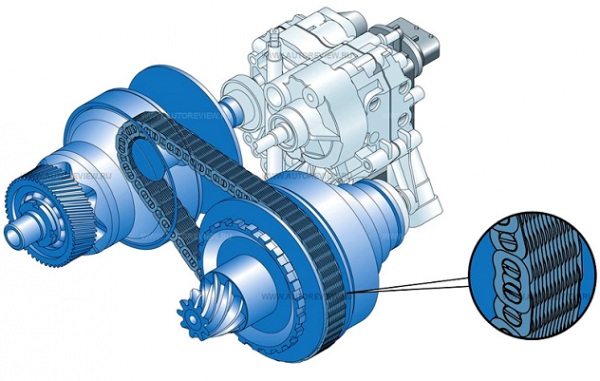

CVT, continuously variable gearboxes, device and principle of operation

The principle of operation of the variator can be explained in simple example. Think of a mountain bike - a chain and two sprockets of different diameters. On rear wheel more stars, which was previously considered an object of extraordinary pride.

It works as follows. Engage a large diameter sprocket and it becomes easier to ride. And on flat road use a smaller diameter sprocket, and although you have to make great efforts, the speed is gained much faster.

The variator works in a similar way, but a belt is used instead of a chain, and sprockets replace pulleys. As on the rear wheel of a mountain bike, the function of several sprockets is performed by one pulley, which is able to change the diameter.

Guided by the ECU commands, the pulley diameter is adjusted. The belt drive is connected by metal plates or a ladder chain. The advantage is obvious - the efficient and comfortable operation of the variator eliminates the jolts and jerks that are characteristic of automatic transmissions.

Disadvantages of the variator:

Combined gearbox

For automatic transmission, a combined principle of operation is used. This type consists of a torque converter and a manual transmission. The manual transmission uses a planetary gearbox, a torque converter (used instead of a clutch) and stepless torque control. Most new automatic transmissions use seven or eight gears.

The advantage of combined automatic transmissions is that the gears switch smoothly, and the reliability of operation is much higher. The downside is much higher fuel consumption and acceleration is slower.

Some types of combined gearboxes use an imitation of manual Steptronic and Tiptronic gearboxes.

Today, automatic transmissions include both a torque converter gearbox, a variator and robotic gearboxes, since they all have electronic control.

In addition, the automatic transmission also includes an adaptive transmission, which is able to take into account the driving style of the car owner.

Hydromechanical automatic transmissions are ideal for small vans or SUVs that prefer comfort over shifting speed.

CVTs will be appreciated by lovers of a measured and smooth ride.

Combined gearboxes are often installed on budget car models. They perfectly cope with the task - maximum fuel economy in urban mode.

The existing varieties of gearboxes, in fact, are the answer to the demand of motorists. The box, together with the steering wheel, makes it possible to effectively control the capabilities of a modern car. Someone likes comfort, someone quickly gets tired of control, someone knows nothing at all and is afraid of everything. In the modern classification, there are three main types of gearboxes and their options:

- mechanical system, manual gear shifting;

- automatic multi-stage gearbox;

- stepless variator system;

- robotic box.

Despite the fact that the latter type is considered a variant of a manual transmission, the existing differences from the classical scheme allow it to be singled out in a separate line. You can safely define it in separate view gearboxes.

The internal combustion engine is not able to work effectively in the widest range of rotational speeds, therefore, various types of gearboxes are used that reduce the rotation speed of the transmission working shafts. This happens either with the help of a set of gears and wheels, as in the main types of gearboxes, or with the help of pushing belts and pulleys - in the CVT scheme of the box.

CVT is most suited to lifestyle modern man and allows you to completely abandon the control of the transmission. The first requires maximum participation of the driver in controlling the speed and torque of the wheels. The machine has greatly facilitated the life of a person behind the wheel, but requires a careful attitude to his work.

Before answering the question - what type of gearbox is better to choose, you should determine your attitude to the car and the degree of your participation in driving.

Simple and reliable manual systems

The mechanical shifting system, also called “mechanics” or “handle”, is the most common and simplest type of gearbox. IN modern cars it comes in two types:

- multi-shaft, in which the gears are on two or three parallel shafts and engage alternately depending on the required gear ratio;

- planetary, in which gears and gear wheels are in constant engagement in several rows, the choice of a pair with the required gear ratio is performed using friction clutches or friction packs.

In wheeled transport, the planetary type of mechanics is used only in automatic transmissions, in mountain bikes and military equipment. The planetary is more compact and lighter than the multi-shaft type of mechanism, but much more expensive to manufacture.

Modern passenger cars with front-wheel drive have a two-shaft scheme and at least 5 gears for moving forward and one reverse. More expensive car models can be equipped with six-speed gearboxes. At the same time, the 5th and 6th are boosting - the output shaft of the gearbox rotates with more high speed engine crankshaft. This is more than enough for manual control.

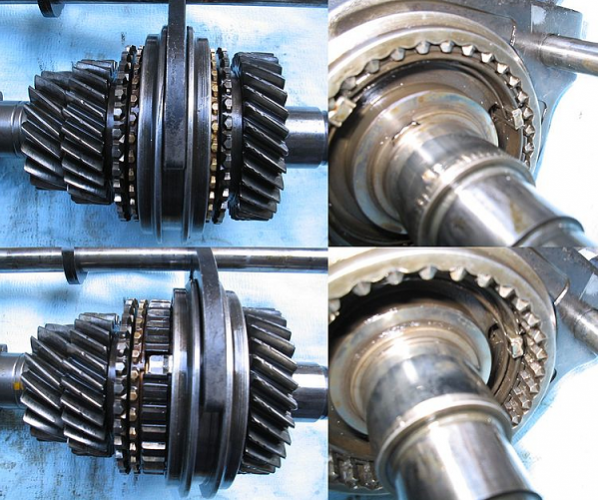

The main problem of a mechanical gearbox is to smoothly and shocklessly engage pairs of helical gears with different angular speeds when shifting on command. To equalize the speed in the box, each pair of gears is equipped with a synchronization ring made of bronze.

When shifting gears, the driver disengages the clutch, thereby allowing the synchronizers to equalize the speeds of rotation of the gears. After that, with the shift knob, either directly or through a system of rods or cable drives, the gear clutch is moved inside the box body, thereby engaging the required pair of gears. It remains only to release the clutch pedal and continue driving.

Such mechanical boxes are called synchronized. It is quite simple and convenient to manage them if you have a certain driving skill. True, incomplete disengagement of the clutch, slippage or other problems with disabling the transmission lead to the fact that the synchronizers of the mechanics begin to wear out intensively, up to the impossibility of engaging the gear without intermediate setting the handle to the neutral position. Shifting to the next gear occurs after re-depressing the clutch. A similar switching method was widely used earlier and is now used on trucks with mechanics that are not equipped with a synchronizer system.

Important! Worn synchronizers, in addition to difficult gear shifting, lead to intensive wear of the gear rims, local chipping of individual sections of the teeth.

A manual transmission is the most reliable and economical, it requires sufficient qualifications from the driver and hard work for constant gear shifting paired with practicing the clutch release pedal. But, oddly enough, many drivers consciously make a choice in favor of mechanics. In their opinion, mechanics, even with increased physical exertion, are more fun to drive a car than robotic or automatic boxes.

Sequential gearbox, as the highest point in the development of mechanics

It would be more accurate to call this box a manual gearbox with a sequential, or in-line, shifting method. The idea came from the field of development for sports high-speed cars. A modern sequential gearbox is built according to the scheme of a conventional mechanical gearbox with an electronically controlled clutch drive and a hydraulic gear shift drive. A feature of the sequential gearbox is the observance of a strict sequence of gears.

Among the advantages of the sequential mechanism are:

- the highest speed of gear shifting;

- observance of the switching sequence makes it possible to "painlessly" work with very high turnover engine and power;

- the control method using the paddle shifters allows you to comfortably control the movement even at high speeds or in difficult road conditions.

In such boxes, spur gears are used and do not use switching synchronizers. Alignment of the speeds of rotation of the gear and the wheel is carried out by a computer using a speed sensor. Instead of a gear clutch, there is a cam gear shift mechanism. Due to this, the speed-on time is approximately 70-80% less than that of conventional mechanics. For the operation of hydraulic drives, a separate unit is used - a high-pressure working fluid accumulator.

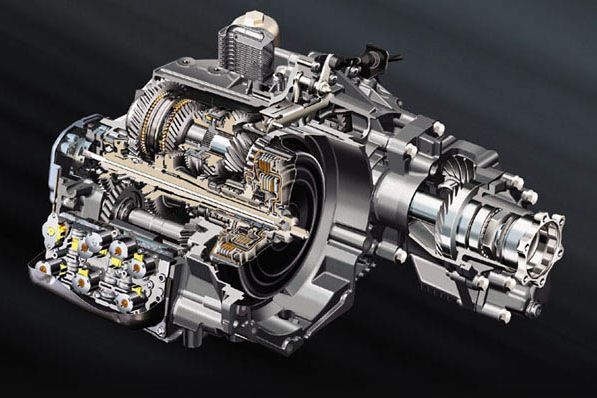

Robotic gearbox systems

Unlike sequential systems, the robotic type of the box has an electromechanical drive for turning on a pair of gears. The basis of the scheme is mechanical box gears, built on a system of two working shaft-rows of gears. Even numbers are collected on one shaft, odd numbers - on the other. Each of the shafts has its own clutch disc and can be turned on and off independently.

This kind of box uses the preselective mode. The trick of the design is that the computer in advance, using data on the mode of operation of the transmission, calculates the most suitable for switching on the next gear. Using a solenoid, it engages it in the opposite gear range with the clutch disengaged. At the moment of switching, it remains only to engage the clutch and continue driving. As a result, switching takes place at a very high speed.

In their own way, robot boxes occupy an intermediate position between automatic boxes and mechanics. At the same time, according to the functions performed and the degree of computerization, this type of box can be called more automatic than existing hydromechanical systems.

The most famous and advertised robotic type of gearbox is the seven-speed DSG system boxes installed on VW models with a small engine size. Reviews about the work - from advertising and laudatory enthusiasm to openly negative.

If you decide to buy a car with a similar transmission system, you should consider the following:

- A robotic box is a very complex mechanism, least of all this type of box is intended for high-speed burning of rubber in crazy races. Boxes are difficult to manage, maintain and repair.

- It takes at least two weeks to get used to driving on the DSG. To fans of mechanics, this view seems slow and unpredictable, to drivers who have moved from hydromechanical boxes - jerking at random.

- Even now, the quality of robots allows us to provide a 5-year warranty and 150,000 mileage.

Interesting! Despite all the criticisms, robots are cheaper to manufacture, have a higher efficiency, and, according to experts, it is possible that this type will displace outdated fluid mechanics from the passenger car market.

The most complex type of transmission - automatic and CVT

The more functions a gearbox performs, the more difficult it is to manufacture, the lower the reliability and the higher the cost. The most expensive and uneconomical have always been and remain all types of automatic car transmissions. The design of this type is represented by hydromechanical and adaptive gearboxes. The scheme is based on two main units - a torque converter and a planetary gearbox.

In modern automatic transmissions, the torque converter acts as a compensator that increases or decreases the main gear of the planetary mechanism by a small amount. Thus, the joint work of the two units provides the optimal number of transmission gears in specific conditions.

Large losses in hydraulics forced engineers to somewhat improve the operation of this type of machine. Now the operation of the torque converter at speeds over 20 km / h is blocked by the clutch, and the torque is transmitted directly through the clutches to the planetary gearbox.

In some cases, instead of connecting a torque converter, its functions in transient conditions are provided by slipping of packages friction linings which is simpler and more efficient.

One of the varieties of automatic transmission is an adaptive automatic transmission, in which the computer control unit selects the most suitable gear ratio in the planetary gearbox.

This type of automatic transmission is still out of competition in the transmission of off-road vehicles, SUVs and cars with a large engine capacity. It is difficult to maintain and repair, requires high qualifications and high-quality consumables.

CVT systems

As a result of 30 years of evolution of the first CVTs for low-power motorized wheelchairs and scooters, technologists managed to bring the level of reliability and durability of the pushing belt (the main element of the stepless CVT) to a completely acceptable mileage of 150 thousand km. The push belt itself is a marvel of engineering. It is made of a large number of absolutely identical metal elements, thanks to which the belt can be flexible and rigid at the same time.

In operation, it interacts with two pulleys - input and output, providing almost any gear ratio of the gearbox. Modern CVTs have received an acceptably high efficiency and the ability to work with engines up to 100 hp. The variator can be called the first of the systems that are truly capable of continuously changing the gear ratio of the transmission.

This type of automation does not like slippage, it is extremely vulnerable to low quality hydraulic fluid. In most cases, the variator is equipped with a torque converter.

Advantages - very accurate selection of the required gear ratio of the transmission. This type of box is capricious, expensive to manufacture and maintain, and is unlikely to leave the small car niche in the near future.

More information about various types Checkpoint on video: