Malfunctions of an automatic transmission. Typical malfunctions of an automatic transmission and their elimination

Why is our article only about modern automatic transmissions, and which gearboxes are considered modern?

The fact is that automatic gearboxes can be either fully hydromechanical or electronically controlled. But automatic transmission of the first type can now only be seen on fairly old cars produced no later than the 1980s. These automatic transmissions are simple and usually reliable, but have long been out of use in the industry (one might say, unfortunately!). However, sometimes they are still found on the market: in specific projects like all-terrain vehicles for Far North and in other special machines for which simplicity of design and reliability are more important than other parameters. By the way, we love and appreciate them very much. By the spring of 2013, our forces will implement a project to install such an automatic transmission on the Niva - motorists, follow the messages on the site!

But your car is most likely equipped with an electronically controlled automatic transmission. So let's move on to the topic of the day. Modern automatic transmissions always have a special electronic control unit (ECU) that works as follows.

The ECU receives signals from various devices in the vehicle - the sensor throttle valve, air flow sensor, camshaft position sensor, engine control unit, ABS control unit and others (in modern cars sometimes there is even a position sensor above sea level!). Full list such devices, using the Volkswagen automatic transmission as an example, see here. Then it processes them in accordance with the algorithms embedded in it and already generates its own signals, which are directly controlled by the gearbox. As you can see, despite the simplicity of the circuit itself, in reality, "electronic brains" are very complex and, alas, are prone to malfunctions, along with malfunctions of the automatic transmission itself.

Thus, all problems with modern automatic transmissions can be divided into several groups:

- Malfunctions in the electronics of the car itself.

- Malfunctions in the automatic transmission electronic control system.

- Malfunctions in the mechanical and hydraulic parts automatic box gear shifting.

These groups of faults are very important to distinguish!

The whole point is that if the problem is only in the computer, or, moreover, not in the gearbox at all, then it is not solved in the slightest by sorting out or replacing the automatic transmission. But these manipulations, unnecessary in this case, increase, sometimes radically, the cost of repairs (if only because troubleshooting in electronics does not require either dismantling or disassembling the automatic transmission).

Sometimes such a repair, which in reality required the replacement of several sensors, turns into a long wait for the car owner, and even costs a pretty penny. So, in addition to contacting experienced and professional specialists, we recommend that you yourself carry out a simple fault assessment before visiting a service center. Well, to help with this, we have selected some typical malfunctions that any owner of a car with an automatic transmission may encounter.

What can they be? We will talk about this in the article.

Automatic transmission has already become commonplace in the automotive world. Driving a car equipped with an automatic transmission is much more comfortable and easier than with a “mechanics”. However, this node is much more complicated, and therefore its failure can result in a "penny". True, the gearbox most often signals the owner of an impending breakdown. How to decipher these signals?

So, every time, leaving the garage or parking lot, the driver must inspect the place where the car was parked. Any wet or oily spots should be suspicious. This is especially true in cases where the liquid has a red or orangeish color and has leaked out in the area of the checkpoint. This is the lubrication of this unit. Of course, if only a couple of drops of lubricant have leaked out, then you can immediately not go to the service station. But you shouldn’t delay with this either, because the leak can increase dramatically at any moment, threatening the failure of the automatic transmission.

Periodically, it is necessary to remove the dipstick to control the oil level in the automatic transmission. In addition to the level of lubrication, it is necessary to pay attention to the consistency and color of the oil. It should be translucent red. If it becomes cloudy, dirty or has a burning smell, it is necessary to change the oil. The last symptom may be another sign of a malfunctioning automatic transmission.

If the switching of stages is accompanied by incomprehensible vibrations and inaccuracies, then most likely diagnostics and repairs will also be required. Most often, these symptoms signal a breakdown in transmission cables. Also, the driver should be alerted by any extraneous sounds, rattle and sharp jerks in the transmission.

As you can see, there are various signs of an automatic transmission malfunction, and in any case, if the slightest deviations in the operation of this mechanism are found, it is necessary to contact a car service to diagnose it. What are the most common breakdowns that automatic transmissions can pursue?

(typography pre_red)"POPULAR" AUTOMATIC BREAKDOWN(/typography)

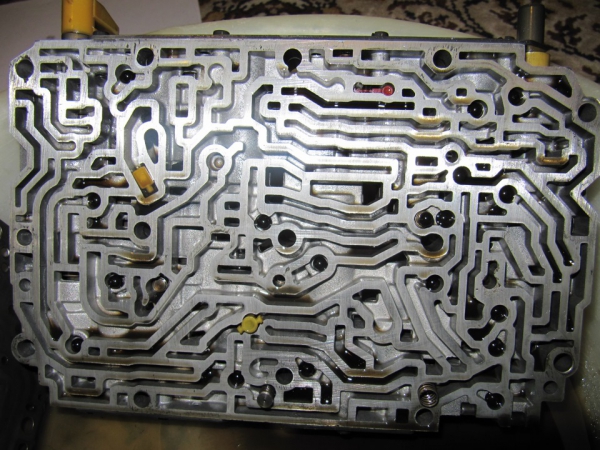

So, the most "popular" malfunction automatic transmission- this is the excessive presence of friction dust in the oil. The main filter cannot stop it, because it settles on the valves of the hydroblock and pre-filters of the solenoids. As a result, the oil pressure is insufficient for normal operation. In such situations, clean the valve body, and also replace the filter and oil.

The plunger bushings of the linear solenoids are eaten away, which leads to loosening of the plungers, which is also fraught with a decrease in pressure in the lines. In such cases, replace bushings or solenoids assemblies.

Plunger valves are also available in the automatic transmission valve body. Over time, they can also begin to seize, which provokes a decrease in oil pressure. Therefore, the valve body must be repaired or completely replaced.

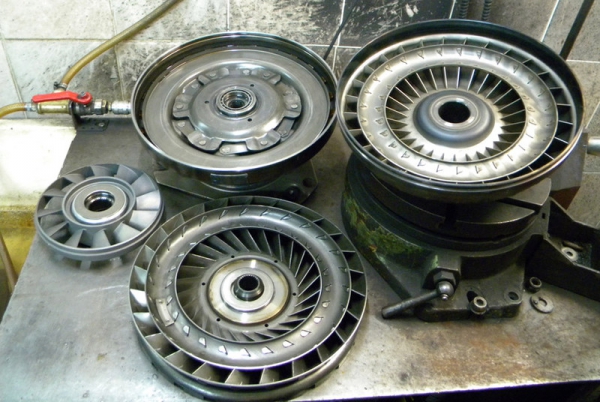

Another “popular” cause of automatic transmission failure is dry running, that is, without oil and subsequent overheating. When the oil level drops even a little, it becomes insufficient to lubricate the shaft bushings. As a result, they are erased very quickly, which leads to an even greater loss of pressure. The most “dry” places are usually the pump bushing, as well as the torque converter. As a result, the owner has to repair both the pump and the torque converter.

In the event of a weakening of the pressure of the pistons on the clutches, which transmit force from the motor to the wheels, the latter begin to slip. As a result, they wear out and heat up, filling the oil with friction dust even more and heating it up. Therefore, if the slightest symptoms of such breakdowns are detected, it is necessary to replace the clutches.

It happens that due to some shortcomings of the manufacturer, the planetary gear sets, hubs, caliper cover have a much larger load than necessary. This is possible if an automatic transmission is installed in tandem with an overly powerful engine. As a result, these parts fail and require replacement. And this is quite an expensive pleasure.

During the operation of the car, a significant load is placed on the automatic transmission, which leads to breakdowns of this unit. IN last years automakers use fairly reliable and modern automatic transmissions, which has significantly reduced the number of such transmission failures. In most cases, automatic transmissions in use today, if properly operated and maintained, may require overhaul with a run of not earlier than 150,000 kilometers. The first thing diagnostics begins with is the removal of computer trouble codes with their subsequent decoding. Then, ideally, contact a specialist - for a more accurate diagnosis.

Automatic transmission malfunctions

Meet completely different signs of a faulty automatic transmission, which can give car owners the necessary information about the nature of the breakdown. So, for example, in case of problems with the valve body, significant shocks appear when shifting gears. Moreover, such shocks are progressive in nature and early stages breakdowns are subtle, and as the problem progresses, such shocks become more and more noticeable. If there are such problems with the automatic transmission, the car owner needs to contact the appropriate service center as soon as possible, whose specialists will carry out all the necessary repairs.

Automatic transmission malfunctions can also be expressed in the complete impossibility of switching the operating modes of the box or blocking work in a certain gear. In this case, the car owner needs to transport a broken car using a tow truck. It is not recommended to drive a car with a broken gearbox on your own, as this can lead to serious damage to the drive and the automatic transmission itself.

IN individual cases a malfunction can be diagnosed using the built-in automatic sensors in the automatic transmission. Such sensors signal an insufficient level of oil pressure in the system, its overheating, or problems with switching stages. At the same time, it must be said that most of these reports of problems with the gearbox are not specific, and it is not possible to make an accurate diagnosis of a breakdown in this case even when using professional computer equipment. The master will need to inspect the transmission, dismantle it, and only after opening it will be able to determine the existing breakdown.

Causes of automatic transmission malfunction - typical

Backstage lever

In old-type automatic transmissions, which had a mechanical connection of the selector directly with the transmission, the link of the automatic transmission lever often fails, which makes it impossible to change the transmission operating modes. Repair in this case consists in replacing the broken selector and gearbox backstage. Such breakdowns are manifested by the difficulty of moving the automatic transmission selector. Ultimately, the lever stops moving and the automatic transmission needs to be repaired. For certain modifications of automatic transmissions, carry out this work possible without dismantling the gearbox itself from the car, which somewhat simplifies the repair work.

Oil leaking

A common malfunction of an automatic transmission is the presence of smudges of oil from under the seals. That is why the car owner is recommended to regularly inspect the condition of the gearbox on a lift or garage pit. If there are any oil smudges on the gearbox itself, it is necessary to contact experienced specialists. In this case, the elimination of such problems is not particularly difficult and consists in replacing the sealing gaskets and changing transmission oil.

Control block

In some cases, there may be problems with the gearbox control unit. The control unit may incorrectly select the speed for gear shifting or block the transmission on its own. Elimination of breakdowns associated with the operation of the control unit and the electrical part of the transmission consists in replacing failed units and control loops.

How to avoid problems?

It must be said that causes of automatic transmission failure can be both objective in nature, caused by physical wear and tear, or be provoked by improper operation of this unit. Many car owners neglect the need for regular transmission oil changes, which leads to lubrication problems and constant overheating of the automatic transmission. As a result, the moving elements of the box quickly fail and require costly repairs.

It is also necessary to properly warm up the transmission in winter time year, which will eliminate problems with the lubrication of moving transmission elements. Low-quality oil disables the solenoids, the replacement of which is a certain complexity and has a high cost. It should also be remembered that automatic transmissions are extremely critical to the aggressive driving style of the car. During prolonged operation of the engine at maximum speed, the clutches of the automatic gearbox can quickly burn out and grind off. That is why it is not recommended to constantly practice an aggressive driving style in a car with an automatic transmission. The complexity of repairing automatic transmissions is due to the fact that a breakdown can only be determined by opening the transmission. To do this, it must be removed from the car, which will determine the nature of the breakdown. It is not possible for most ordinary motorists to independently perform high-quality repairs of an automatic transmission, so you need to contact specialized service centers. Repair work consists in replacing damaged elements, which allows you to restore the functionality of the entire automatic transmission. It should be noted that due to the structural complexity, the repair of automatic transmissions is laborious and expensive.

Table of signs and causes of automatic transmission malfunction

The table of typical automatic transmission malfunctions, which is located at the bottom of the article, presents the most common automatic transmission malfunctions.

Vehicle not moving forward. Slips. Reverse speed is in working mode.

3. Clutch rings worn

4. One of the valves of the hydraulic unit is stuck.

No reverse gear. There are only 1st and 2nd speed, 3rd and 4th speed is missing.

1. Worn friction disc of a specific clutch.

2. Wear or breakage of the clutch piston cuffs.

3. Worn or broken clutch oil o-rings.

The machine is not moving backwards or forwards. When shifting into P or N, as well as into any gear, there is a strong push, there is a speed change - but still no movement.

1. Torque converter problem

2. Add oil.

3. Change the oil filter.

Driving in 3rd gear only

1. Worn friction discs, forward clutches.

2. Wear or breakage of the clutch piston cuffs.

3. Clutch rings worn

4. Valve body stuck

The car system considered a malfunction and switched the automatic transmission to Emergency mode. Diagnostics required and ready for repair.

Switching on an unheated box (to a cold one) is made with a push. Dirty hydraulic plate or solenoids. Diagnostics and cleaning of the valve body is required. Consumables may need to be replaced.

Absent reverse gear.

1. The brake band is worn out.

2. Wear or breakage of the brake band piston cuffs.

3. The piston rod of the brake band broke off.

4. Malfunctions of the braking system (package)

The machine does not move backward or forward. Switching from "P" or "N" to any speed occurs without a noticeable push into gear.

1. Torque converter problem.

2. Faulty oil pump drive gear. There is no clutch with the torque converter

3. Add oil

4. The filter screen is dirty (clean).

5. Worn friction discs, clutch and brake band.

6. Deterioration of cuffs of pistons of packages.

7. Worn or broken clutch oil o-rings.

8. The problem is in the solenoid or in one of the valve body valves.

The growing rumble of the automatic transmission, vibration when driving, other strange sounds. They increase depending on the engine speed.

One of the bearings is worn out.

There is a reverse gear, the front ones are switched on only 1 and 2, there is no shifting to subsequent gears. After warming up the automatic transmission and oil, the problem may disappear.

A clogged valve in the valve body or a solenoid sticks.

The car moves with the selector position in "N".

1. Poor adjustment of the cable or lever of the automatic transmission control drive.

2. Seizure of the piston of one of the clutches (direction forward).

3. Friction discs welded with the rest

Gear shifting at high speeds

1. Incorrect throttle cable adjustment.

2. Clogged filter

3. Throttle valve malfunctions

The car is moving properly, but on a long climb on the last. the speed of the machine slips and switches to a lower one.

1. Check the oil level (ATF) in the automatic transmission

2. Worn friction discs, clutch and brake band.

3. "Tired" oil pump.

4. Faulty valve body solenoids or maximum wear of the valve body passages.

A sharp press on the gas pedal does not lead to a downshift (kickdown).

1. Faulty sensor or button under the kickdown pedal.

2. Seizure of the valve of the hydraulic block of switching to down. transfer

Z. Malfunction with cable control. throttle valve

4. Open circuit of the kickdown sensor.

When the car starts off, slip occurs, but after picking up speed it continues to move properly, the automatic transmission switches to other speeds.

1. Large wear of the splines of the turbine wheel hub due to which the automatic transmission shaft slips

2. Wear or breakage of the clutch piston cuffs.

Slipping when shifting gears.

1. Clogged filter

2. Check the oil

3. Pump failure

No movement back and forth

Cut splines in the hub of the turbine wheel of the gas turbine engine

When shifting automatic transmission, strong shocks occur

1. Friction discs are badly worn.

2. The tubules of the valve body or solenoids are clogged.

3. Brake band worn out

The car stalls while driving and jerks when shifting gears

Clutch failure

No movement back and forth

No line pressure

1. The splines of the oil pump shaft in the housing of the front cover of the torque converter are cut off.

2. Cut the splines on the oil pump reactor shaft.

The movement of the car is normal until the oil warms up. Then slippage begins, in the end the car remains motionless.

1. Friction disc problem

Note: as long as the oil is not warmed up, its viscosity and pressure are slightly higher than when hot, worn discs are pressed against each other more strongly, thereby creating traction.

2. Torque converter clutch worn The oil contains a high amount of dust from the friction discs. Leads to a clogged filter mesh.

Noise resembling the beating of a metal object at idle

1. Fritz. the disks of one of the drums are heavily worn

Automatic transmission will not switch to downshift with a “sneaker on the floor”, the revolutions do not develop in order to increase the speed of the car. There is no kickdown.

1. The problem is related to the operation of the engine.

Lack of downshifting with a “sneaker on the floor”, revolutions do not develop in order to increase the speed of the car. There is no kickdown.

The movement of the car is normal until the oil warms up. Then slippage begins, in the end the car remains motionless.

The car gets under way and the speed is gained extremely slowly. The problem is the same with reverse gear.

1. Check the tightness of the fan blades of the pump or turbine wheel.

2. Breakage of the same blades

You have found iron particles in the pan of a car. The shape is sharp, large enough, exceeding 1 mm The end of the life of the planetary gear may be coming.

Foaming oil in the machine. Uncharacteristic color of automatic transmission oil. Possible slippage of the car.

Water got inside the automatic transmission (automatic transmission)

Line oil pressure is low

1. Dirty valve body or solenoids.

2. Need to check the oil level

3. Check the reset valve in the oil pump.

After turning on the speed, the car troit and stalls. If you increase the speed and turn off the gas, there is movement.

1. Check the shift valves

2. Problems of the automatic transmission torque converter

Aluminum particles at the bottom of the pallet.

1. The sliding bearing is worn to the limit.

2. Perhaps the end of the life of the planetary gear is coming.

Particles of plastic material detected

1. Plastic sleeve

2. Breakage of any plastic element.

metal scraping

1. Differential gear wear

2. Differential bearing wear.

Magnetized rollers found in pallet

1. The thrust roller bearing is destroyed.

Nowadays, when buying a car, motorists increasingly prefer cars with automatic transmission. It is actually not surprising, now there are a lot of cars in cities, traffic has become denser, even in small cities traffic jams, hitherto known only to megacities, have begun to appear, and in these conditions it is quite logical that using an automatic machine is more convenient.

There are three types of automatic transmissions:

1. Torque converter machine

Today we would dwell in more detail on the good old, already partly considered obsolete by some manufacturers, the classic torque converter machine.

Despite big variety brands of cars, not all automakers are engaged in the production of their own boxes. The most famous manufacturers of automatic transmissions: Aisin Seiki Co Ltd (Japan), JATCO Ltd. (Japan), Getrag (Germany), ZF Friedrichshafen AG (Germany), BORG WARNER (Germany), GM (USA)…

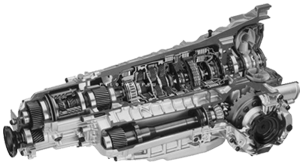

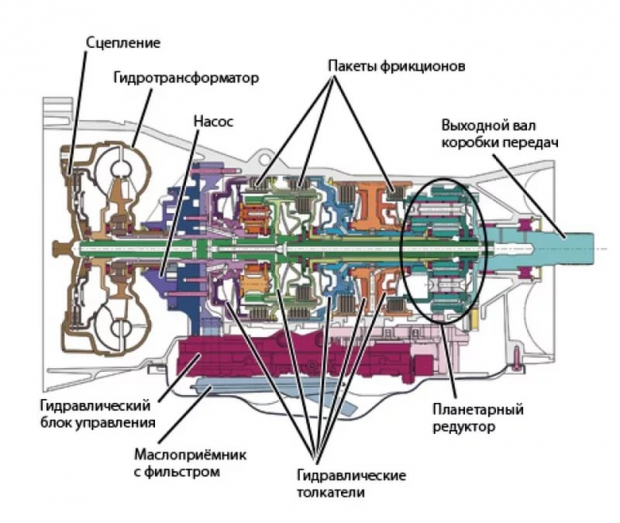

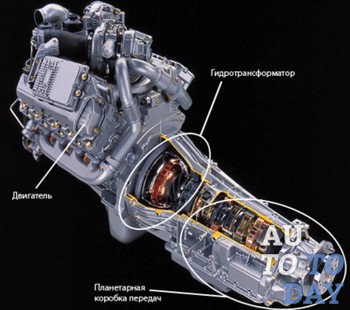

The automatic transmission is a combination of three sciences: mechanics, hydraulics and electrics. The mechanics are directly responsible for shifting gears, hydraulics - for transmitting torque to the mechanical part, and electrical - is designed to orchestrate all this and provide communication between the automatic transmission and other vehicle systems.

What does the automatic transmission consist of:

1. A torque converter is a device that serves to transmit and convert torque from an engine to an automatic transmission planetary gear set.

2. Planetary gear - an automatic transmission part, which is a set of sprockets that change the gear ratio in different ratios.

3. Brake band, rear clutch, front clutch - automatic transmission parts responsible for changing the ratio of the gear ratio in the planetary gear.

4. Control device, which consists of a pump, hydraulic block or valve plate and oil exchanger.

In order for the automatic transmission to work properly, it must be serviced. Compared to a mechanical transmission, it is more demanding on the quality of the oil and on the operating modes.

Manufacturers of automatic transmissions recommend changing the oil and filter in the unit at least every 90,000 km. But as practice shows, it is better to shorten this interval to 60,000 km, since if you mostly drive in urban mode, the oil degradation process is faster due to the large number of engine hours worked.

Consider the frequent and most common problems that the owner of a car equipped with an automatic transmission may encounter. In any case, far from many will be able to fix the automatic transmission malfunction on the knee, on the side of the road or in their garage, and in 99% of cases the help of a qualified mechanic is needed, since the “automatic” is no less complicated than the motor.

If there is any problem with the automatic transmission, a warning lamp lights up on the dashboard of the car, and the transmission enters emergency mode.

1. The main reason, and the simplest reason why the box can get into an “accident” is the low level of gear oil. Now the bulk of modern boxes are equipped with a measuring bolt, by unscrewing which, by the intensity of ATF leakage (or by its non-outflow), determine the oil level in the box. Boxes older than those produced in 2010 are often equipped with an ordinary dipstick, by removing which you can check not only the level, but also the condition of the transmission fluid.

2. In an “accident”, the box can get up from overheating of the transmission oil, which occurs due to strong slippage of the clutches. Most often this is due to the fact that the oil in the unit has not been changed for a long time. In this case, changing the fluid along with the filter element can correct the situation. If the oil change did not help, then the problem lies much more serious, and this may be a malfunction of the pump and / or solenoids, clutches, or this may be due to a malfunction of the automatic transmission control unit.

Also, due to dirty, used-up oil, the automatic transmission can make jerks when shifting while driving.

3. Mechanical failures of the box or hydraulics. If you go from simple to complex, this can occur from a change in the geometry of the body of the box itself, for example, due to an impact during an accident. In this regard, oil leakage and damage to the gearbox clutches may occur. In this case, only complete analysis unit with a defective each of the transmission elements, checking for the presence of metal fragments of the automatic transmission case and fragments of parts. The electronic diagnostics of the box can also partially tell about malfunctions, but most often it turns out that the matter lies precisely in a mechanical malfunction.

4. Problems of the automatic transmission electronic control system. It can be, like ordinary power outages, oxidized "chips" of sensor connectors before a software failure of the automatic transmission computer. This problem can be eliminated by checking the integrity of all wiring from the control units to the sensor chips with their trial replacement. If ringing the wiring did not help, it may be a software failure or a malfunction of the box ECU itself, and in this case, the unit may need to be flashed or replaced.

Also the reason for the transition to emergency mode an automatic transmission can be a failure of the crankshaft position, camshafts, MAF sensor, and position sensor. Reading and decoding errors will help to find out the exact cause.

Automatic transmission is a complex organism that requires attention and qualified maintenance, as well as repairs, if any. All this is very expensive, requires a lot of time and scrupulousness in repair. But do not think that the breakdown of the automatic transmission is immediately her death. Each automatic transmission has its own repair kit, by purchasing which you can overhaul the unit, and it will again serve you faithfully.

Today, there are a lot of myths about automatic transmission malfunctions. One way or another, for many, the reliability of some types of automatic transmissions is in doubt. There are many factors that affect the performance of an automatic transmission, such as improper use, shifting errors, heavy duty operation due to bad roads, etc.

In this material, we will consider the design, the main types of malfunctions of the machine, we will tell you what signs indicate these malfunctions and how to eliminate them.

Structure of the automatic transmission

We will not talk in detail about the design features of the automatic transmission, but only mention the most important thing.

The automatic transmission includes such elements as:

1. For starters, this is the gearbox itself with a set of gearboxes.

2. Hydraulic transformer (instead of conventional clutch

3. Gear change device (friction clutches, brake band and other parts).

4. Distribution block (required to transfer oil to the hydraulic pushers that "push" the gear unit).

5.

The automatic transmission control unit is the main computer of the machine. It serves to drive the hydraulic part based on the readings of the sensors of the machine.

5.

The automatic transmission control unit is the main computer of the machine. It serves to drive the hydraulic part based on the readings of the sensors of the machine.

The main breakdowns of automatic transmission and how to eliminate them

There are several symptoms of a problem:

1. There is no forward movement, the car is stationary, the reverse speed is working.

Possible reasons:

The friction discs of the forward clutch C1 are worn out. In this case, they must be replaced.

There was a break or wear of the cuffs of the piston of the forward clutch C1. The solution to the problem is to replace the cuffs.

The oil o-rings in the C1 forward clutch are worn out. To solve the problem, it is necessary to replace the sealing rings.

Shift valve from 1st to 2nd gear stuck. In this case, it is necessary to disassemble the valve assembly and clean the valve.

2. There is no backward movement, there is first and second speed, but there is no third.

The reasons for such a malfunction may be:

The friction discs of the forward clutch C2 are worn out. The solution to problems is the replacement of friction discs.

C2 forward clutch piston seals are broken or worn. In this case, we replace the cuffs.

C2 forward clutch oil o-rings are broken or worn. Then you need to change these rings.

The splined joint in the sun gear drum housing has been sheared off. The solution to the problem is to replace the broken element with a new one.

3. There is no reverse movement, and all forward shifts work.

Possible reasons:

The friction layer on the brake band has worn out. The brake band needs to be changed.

Wear or breakage of the piston cuffs of this clutch. With such a malfunction, we replace the cuffs on the piston.

The brake band piston rod has broken. You can fix such a breakdown by replacing the defective part.

Malfunction of the automatic transmission control unit

You can determine such a malfunction by the constant glow of the emergency mode lamp. To verify this, you need to conduct computer diagnostics. Most often, it becomes necessary to replace the node.

You can determine such a malfunction by the constant glow of the emergency mode lamp. To verify this, you need to conduct computer diagnostics. Most often, it becomes necessary to replace the node.

If the automatic transmission control unit is broken, then the correct solution would be to replace the unit, but you will have to fork out well to replace it. Sometimes repairs can help, but this is not always possible.

Sensor failure

The following sensors may fail: ABS, camshaft, air flow. In the event of such a breakdown, the emergency light is not on all the time, but only when the car is accelerating and while the car is braking.

The malfunction is detected by computer diagnostics. Solve the problem by repair faulty sensor does not always work, so the best option there will be a sensor replacement, but please note that sensors are expensive.

Problems with contacts or wiring

There can be many reasons for problems with contacts or wiring - this is either a broken wire, or oxidation of contacts, or a short circuit, and so on. If the whole problem lies in this, then the emergency mode light will light up randomly, chaotically. Perhaps it will burn all the time, or it may not light up at all.

In order to find out the cause of this malfunction, it is necessary to look for a bad contact or a broken wire, for which you need to look through the entire wiring. This work is very tedious, time-consuming and expensive. In a car service, you will have to fork out, because sometimes you need to remove all the wiring.

Malfunction of the sensor of rotation of the shafts of the "machine"

It is easy to determine the malfunction of the shaft rotation sensor of the “machine” (either input or output). The emergency light comes on when the automatic transmission handle is moved to position D. Such a signal may also appear when the handle is moved to any position. You can identify such a breakdown when referring to computer diagnostics.

It is easy to determine the malfunction of the shaft rotation sensor of the “machine” (either input or output). The emergency light comes on when the automatic transmission handle is moved to position D. Such a signal may also appear when the handle is moved to any position. You can identify such a breakdown when referring to computer diagnostics.

This sensor cannot be repaired. Therefore, it must be replaced with a new one. The work on replacing the sensor will take quite a bit of time. The cost of these works will be acceptable.

The occurrence of a problem with the solenoid "machine" or electronic pressure regulators

When such a breakdown occurs, the emergency light may not light up at all, or it may not light up in every mode, but only during some switching. But from the mechanical side, everything will be clear. There will be no gear shifting, severe slipping or shock may occur.

More accurate data can be obtained by conducting computer diagnostics. If we take the task seriously, then it is necessary to measure some basic parameters, for example, measure the inductance or resistance of the circuit.

The solution to the problem is to replace the broken solenoid or pressure regulator. Less often, it is necessary to replace the entire assembly, and this is an expensive job. It is often impractical to repair the unit because it can sometimes cost more than buying a new unit.

Occurrence of a malfunction of the oil temperature sensor

In the event of such a malfunction, the automatic transmission may enter emergency mode either after the oil has warmed up, or immediately after the machine is started. Computer diagnostics will help to identify such a malfunction. The way out is to replace the aforementioned sensor.

Malfunction of the automatic transmission selector position sensor

The signal for the formation of such a malfunction will be the indication of gear icons that will not correspond to the actual position of the handle. Sometimes this may not happen, and the box will work as usual. And only computer diagnostics will help to see this malfunction.

The signal for the formation of such a malfunction will be the indication of gear icons that will not correspond to the actual position of the handle. Sometimes this may not happen, and the box will work as usual. And only computer diagnostics will help to see this malfunction.

There is another method for detecting such a malfunction - this is alternately switching the handle and observing the bulbs. The cost of replacing this sensor is not too high. In some cases, the sensor can be disassembled and the broken part replaced. Only in this case it is necessary to check if there is any oxidation on the contacts.

If you find any of the malfunctions of the automatic transmission, it is best to immediately contact the service.

Subscribe to our feeds