Automatic malfunction box and their definition. Test in the "P" range. Problems with the backstage of the automatic transmission lever

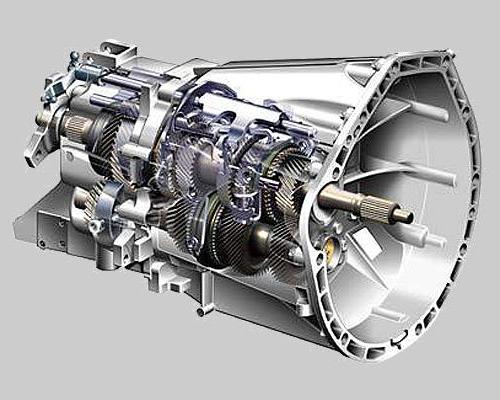

Every year the number of cars with automatic transmission increases. There are reasons for that. An automatic transmission is much more convenient to use than a manual transmission. With it, the driver does not get tired in traffic jams, and with proper operation there are no problems with the clutch. But the device automatic box slightly more complicated mechanics. One of the main components of any automatic transmission is a torque converter (in the common people "donut"). Over time, it may fail. Why does this happen and what are the signs of a malfunctioning automatic transmission torque converter? Let's take a look at our today's article.

About design

The torque converter is used to change and transmit torque that comes from the engine to the gearbox. The element design includes:

- Pump wheel.

- Turbine.

- Reactor wheel.

- Freewheel clutch.

- Locking clutch.

GDT is placed in a separate housing, which is filled with ATP liquid. The latter performs the function of not only lubrication, but also a “wet” clutch (since there is no basket and disc as such in the automatic box). The “donut” works in a closed cycle. First, the ATP liquid enters the turbine, and then the reactor wheel. The speed of the blades of the latter begins to increase. The fluid flow is directed to the pump wheel. As a result, the amount of torque increases. With an increase in the frequency of rotation of the crankshaft, the angular velocity of the turbine and pump wheels equalizes. The flow of ATP fluid begins to change its direction. At the same time, the freewheel is activated. The reactor wheel begins to rotate.

With a further increase in the rotation speed, the torque converter is blocked (a special clutch is put into operation). So, the transmission of torque from the motor to the box is done directly. This occurs until the next transmission is switched on or off.

The operation of the torque converter is controlled by an electronic control unit. It receives information from all sensors that are in the "donut" and generates an output signal. If any problems occur, the electronics will immediately report an error. In practice, the automatic transmission torque converter is blocked. Symptoms of a malfunction may vary. This is both electronics and mechanical part. But if the box is in emergency mode, it should definitely be diagnosed.

How long does it serve?

Typically, the torque converter is designed for the entire life of the automatic transmission. This is 250-300 thousand kilometers. Old "Mercedes" torque converters (4AKPP) can take care of 500 thousand each. Malfunctions of the torque converter of the automatic transmission "Toyota Mark-2" of the 80s also rarely occur. But like any other mechanism, it can fail earlier. To prevent serious repairs, you need to detect a breakdown in time and know the signs of a malfunction of the automatic transmission torque converter. We list the most characteristic of them below.

Sounds, vibration

How to independently determine the signs of a malfunction of the automatic transmission torque converter? First of all, you need to listen to the work of the box itself. So, when shifting gears, a mechanical sound (rustling) may occur. It is barely noticeable at first. And when the engine speed increases, it disappears altogether. What does it say? Such signs of a malfunctioning automatic transmission torque converter indicate a problem with needle-type thrust bearings. The element is located between the torque converter cover and the turbine (or reactor) wheel.  If a loud metallic knock occurs when shifting gears, this indicates deformation of the turbine wheel blades. Such an element is no longer subject to repair.

If a loud metallic knock occurs when shifting gears, this indicates deformation of the turbine wheel blades. Such an element is no longer subject to repair.

If a slight vibration occurs at speeds of 60-90 kilometers per hour, this indicates a clogged oil filter. Also, similar symptoms occur due to poor-quality or old ATP fluid. The solution to the problem is to change the filter and oil. In most cases, the repair ends here.

Many use a partial oil change - drain some of the old and add new, repeating the steps 2-3 times. But experts recommend not saving on the complete replacement of the ATP fluid. It is produced on a pressure bench.  What is the advantage of such a procedure? The oil change will be done 100 percent, and the dirt from the box will be completely washed out. It is impossible to repeat this in a garage - only if there is a stand.

What is the advantage of such a procedure? The oil change will be done 100 percent, and the dirt from the box will be completely washed out. It is impossible to repeat this in a garage - only if there is a stand.

Emergency mode

It implies the operation of the transmission only at the first three speeds. How to determine the malfunction of the automatic transmission torque converter? On modern cars, an additional warning is displayed on the instrument panel. The box can get into emergency mode for various reasons:

- Damage to gearbox housing.

- The presence of chips in the ATP fluid.

- The presence of metal fragments of the turbine.

- Malfunctions of the friction group and clutch.

Remarkably, the box can enter emergency mode only periodically. For example, after heating the ATP liquid to certain temperatures. The reason must be sought in the sensors (air flow, camshaft and even the ABS system). If the box gets into an accident unexpectedly, it is worth examining the integrity of the electrical wiring.

When shifting from first to second gear, a thud may be felt in D mode. These signs of a malfunction of the automatic transmission torque converter may also be accompanied by vibration. In this case, the problem is solved by scanning the input and output sensors. There are other symptoms of a malfunctioning automatic transmission torque converter. We will talk about them further.

Problems with dynamics

The vehicle may not accelerate well. There are many reasons for this, but if we consider the signs of a malfunction of the automatic transmission torque converter (including BMW), then this is an overrunning clutch. If it fails, the gas turbine engine should be disassembled and the broken part replaced.  Sometimes it happens that after stopping the car and can not start at all. This indicates damage to the spline on the turbine wheel. The way out of the situation is the installation of new slots. In advanced cases, it is necessary to change the entire turbine wheel.

Sometimes it happens that after stopping the car and can not start at all. This indicates damage to the spline on the turbine wheel. The way out of the situation is the installation of new slots. In advanced cases, it is necessary to change the entire turbine wheel.

Smell of burnt plastic

This may occur on parked car. The smell of burnt plastic is felt in the area of \u200b\u200bthe gearbox. What does it say? Similar signs of a malfunction of the automatic transmission torque converter (including Toyotas) occur due to overheating and melting of the polymer parts of the donut. This is the result of a clogged oil cooler. It can be located both in the box itself and separately from it. A good automatic transmission cooling system is the key to reliable operation of the torque converter.

Engine stalls

When attempting to shift the transmission up or downshift, the motor starts to stall. This is due to failures in the electronics, which blocks the operation of the torque converter. Often the culprit of the problem is the electronic control unit. But we will talk about it more below.

Causes of incorrect operation of the gas turbine

Experts identify several factors that can affect the operation of a hydraulic transformer:

- Automatic transmission lever yoke.

- Oil (ATP liquid).

- Electronic control unit for automatic transmission.

Let's consider these problems in more detail.

backstage

Over the years, in an old-type automatic transmission, the backstage can fail. Such units have a mechanical connection between the selector and the box. This makes it difficult to turn on the necessary gearshift mode. The selector sticks in one position. The way out of the situation is to replace the selector and backstage. In some cars, this operation can be done without dismantling the gearbox itself.

Oil

The resource and serviceability of the automatic transmission largely depends on the state of the ATP fluid. Experts recommend replacing it every 40-50 thousand kilometers. However, timely replacement is not yet a guarantee of long-term operation of the torque converter. In the case of drips and a low level of ATP fluid, the donut will fail very quickly.  How to make a quick diagnosis? You need to start the engine, open the hood and get the automatic transmission oil dipstick. It has the inscription "Cold" or "HOT". In the first case, it is not necessary to warm up the box. If the level is below normal, it urgently needs to be renewed. Liquid is poured through the same hole for the probe.

How to make a quick diagnosis? You need to start the engine, open the hood and get the automatic transmission oil dipstick. It has the inscription "Cold" or "HOT". In the first case, it is not necessary to warm up the box. If the level is below normal, it urgently needs to be renewed. Liquid is poured through the same hole for the probe.

Pay attention to the condition of the oil itself. So it is possible to identify and prevent malfunctions associated with the torque converter in time. The presence of chips on the probe is excluded. If this is the case, then either the turbine or reactor wheel has failed, or the end washer has worn out.

Note! When operating an automatic transmission with a low level of ATP fluid, the gas turbine engine may overheat.

Periodically inspect the bottom of the car, namely the cover (pan) of the automatic box. Sometimes seals can leak. It is undesirable to operate a car with such a malfunction, since the oil level can drop at any time.

Electronic control unit

This is the main node that controls the operation of the automatic box. In the event of a malfunction, the unit may incorrectly select the speed for switching speeds, or completely block the operation of the transmission. The ECU is a fairly reliable mechanism, but when exposed to certain factors, it fails. It can be:

- Sudden voltage drops on the on-board network.

- Mechanical shocks, vibrations.

- Elevated temperature.

- High humidity.

- Insulation damage and contact oxidation.

Breakdowns associated with the electronic unit are solved by its complete replacement or by installing new separate control loops.

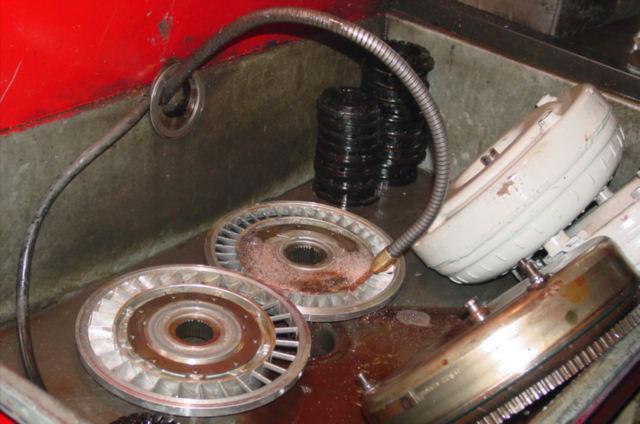

Hydroblock problems

Malfunctions of the automatic transmission torque converter can also occur due to the valve body. Outwardly, it is a kind of plate and looks like this:  The valve body is used to transfer ATP fluid under pressure through certain channels in order to turn on or off a specific gear. In the event of malfunctions, this plate can provoke vibrations and shocks when changing the transmission operating mode. These are the main signs of a malfunctioning automatic transmission torque converter. On modern cars valve body malfunction is displayed on on-board computer. Also, the plate does not tolerate high and prolonged loads. This could be towing a heavy vehicle or starting with two pedals.

The valve body is used to transfer ATP fluid under pressure through certain channels in order to turn on or off a specific gear. In the event of malfunctions, this plate can provoke vibrations and shocks when changing the transmission operating mode. These are the main signs of a malfunctioning automatic transmission torque converter. On modern cars valve body malfunction is displayed on on-board computer. Also, the plate does not tolerate high and prolonged loads. This could be towing a heavy vehicle or starting with two pedals.  Often, automatic transmission torque converter malfunctions occur in winter. This is a consequence of the operation of the box with cold ATP liquid. At temperatures below -5 degrees, the automatic transmission needs to be warmed up. This is done simply. It is necessary to turn on all modes (Parking, Neutral and Drive) in turn, without starting the movement, with an interval of 5-10 seconds. This will warm up the oil and prevent damage to the automatic transmission torque converter. Working temperature for ATP liquid - 75-80 degrees Celsius.

Often, automatic transmission torque converter malfunctions occur in winter. This is a consequence of the operation of the box with cold ATP liquid. At temperatures below -5 degrees, the automatic transmission needs to be warmed up. This is done simply. It is necessary to turn on all modes (Parking, Neutral and Drive) in turn, without starting the movement, with an interval of 5-10 seconds. This will warm up the oil and prevent damage to the automatic transmission torque converter. Working temperature for ATP liquid - 75-80 degrees Celsius.

Conclusion

So, we found out the main signs and causes of malfunctions of the automatic transmission torque converter. In most cases, a breakdown is accompanied by errors on the dashboard and the characteristic sound of the box itself. When kicks and vibrations appear, detailed diagnostics should be applied. Depending on the scale of the problem, this is solved by changing the oil or parts of the torque converter itself (turbine wheel, bearings). Timely detection of faults will allow you to avoid serious repairs.

Foreign cars sold in Russia are often equipped with an automatic transmission. Such a unit is much more convenient and comfortable, especially when driving around the city. Typically, automatic transmissions have a fairly long resource and, with timely and competent maintenance, can work for a very long time. Almost all malfunctions occur due to the fault of the owners themselves, who do not understand the maintenance of automatic transmissions.

Peculiarities

Japanese automatic transmissions ("Toyota Corolla" is also equipped with it) are one of the most reliable. In Russia, you can still see the old "Crown" and "Marks" with their own and never even repaired transmission, despite the fact that they are already in their third decade. It is worth noting that some modern automatic transmission models that are put on luxury modifications of Toyota and Lexus do not require maintenance. This, of course, does not mean that automatic transmission oil (including Toyota Crown) does not need to be changed at all. And many do. The fluid resource is no more than 60 thousand kilometers. Further, the oil begins to turn black and loses protective properties. But this is not the only factor affecting the resource. Unfortunately, modern trend to the complexity of the design leads to a decrease in reliability.

Main problems and malfunctions

Typical problems with are largely similar for different brands, including automatic transmissions (Toyota Mark-2 is no exception):

- A decrease in the oil level in the box, which is caused by a violation of the integrity of the block and the transmission pipes. The culprits may be burnt gaskets, old cracked pipes. The oil level must be checked and topped up if necessary. It is worth noting that oil for manual transmissions is by no means subject to operation on automatic ones due to its higher viscosity.

- All gears are not included, except reverse, or vice versa. This is due to wear of the clutches or the clutch itself. To eliminate, of course, you will have to remove the box and open it, making a visual inspection.

- It happens that the third and fourth gears do not turn on. The reason for this may be the wear of the friction clutches, the breakage of the piston cuff or damage to the splines.

- Gears do not turn on, the car is at a standstill. There may be several reasons for this. This is an insufficient oil level, wear of the friction clutches and their pistons, breakage of the clutch.

- Slip when starting off - wear of the torque converter shaft or malfunction of the clutch clutch.

- The movement of the car in the neutral position - sticking of the switching piston, connection of the discs due to overheating. Sometimes the adjustment of the shift lever is violated.

- The inclusion of the transfer and the start of the car from a place only after warming up. Here, most likely, there is wear on the clutches, which do not provide torque transmission.

Features of automatic transmission operation

When operating an automatic transmission, first of all, you need to monitor the radiator, to prevent contamination.

It must be remembered that the automatic transmission heats up during operation, and when driving off-road, an additional radiator is often needed. Damage to the cooling system can cause the oil to overheat. As a result, burning of sealing rings and friction clutches. Thus, compliance with the automatic transmission temperature regime is one of the most important conditions for trouble-free driving.

Features of the selection and replacement of oil

Automatic transmissions are designed so that the quality and lubricity of the oil are the most important factors affecting its durability. Any deviation from the norms can be detrimental to the unit. Therefore, it is so important to observe the service interval, guided by the oil change table for a particular model.

Aisin automatic transmission malfunctions

The supplier of gearboxes for these vehicles for many years has been Aisin, which specializes exclusively in these automotive units. But, in keeping with the trends of the times, the simple design of these boxes is a thing of the past.

New multi-stage units with complex control algorithms and a switching system have appeared. But, as in any mechanism, the complexity of the design entails a decrease in reliability. Unfortunately, there are typical diseases in the Toyota automatic transmission.

"Toyota Rav-4"

These SUVs are equipped with a U140 series box (not to be confused with the one that is placed on the Camry). This unit is deservedly popular due to its durability and reliability. But weakness There is also electronics here. This series equipped with electronic protection against breakage. When turned on, it blocks the operation of the unit completely. This is treated by replacing the electronic control unit.

"Toyota Corolla"

This model is not only one of the oldest in model range Toyota, so it is also the most reliable. The most common automatic transmission (Toyota Corolla is also popular thanks to it) is the 4-speed U341F series, which has already earned itself the highest reputation. But sometimes it breaks down too.  The main ailment is the failure of the hydraulic plate, which entails the replacement of the gearbox solenoids block. On the latest generations of this Toyota model, a “robot” installs. This mechanical boxes gears with automatic electronic control. For such units, the clutch is controlled by a separate unit, which, in case of malfunction or partial breakdown, gives commands to frequently engage and disengage the clutch.

The main ailment is the failure of the hydraulic plate, which entails the replacement of the gearbox solenoids block. On the latest generations of this Toyota model, a “robot” installs. This mechanical boxes gears with automatic electronic control. For such units, the clutch is controlled by a separate unit, which, in case of malfunction or partial breakdown, gives commands to frequently engage and disengage the clutch.  This leads to slippage. The electronic control unit can be replaced, and everything will be in order. However, if this is not done in a timely manner, the clutch itself will need to be repaired, since multiple on-off switches in no way contribute to the durability of this assembly.

This leads to slippage. The electronic control unit can be replaced, and everything will be in order. However, if this is not done in a timely manner, the clutch itself will need to be repaired, since multiple on-off switches in no way contribute to the durability of this assembly.

Toyota Camry automatic transmissions

The first generations of Camry were equipped with the A540E series gearbox.  This model has gone through several modifications during its production. Moreover, they are rarely interchangeable: the same nodes, depending on the year of manufacture, are completely different. This gearbox is quite a rarity in Russia. And in the event of a breakdown, serious problems with spare parts can arise. The U140E and U240E automatic transmissions are installed on the new generations of Toyota Camry. The first - for 2.4 liter engines, the second - for 3-liter engines. The weaker U140E is poorly adapted to the lower mass of the machine and, as a result, cannot boast of high reliability. A frequent breakdown on it is the failure of the back cover. This leads to burning of the clutches, slipping of the clutch, increased engine speed and breakdown.

This model has gone through several modifications during its production. Moreover, they are rarely interchangeable: the same nodes, depending on the year of manufacture, are completely different. This gearbox is quite a rarity in Russia. And in the event of a breakdown, serious problems with spare parts can arise. The U140E and U240E automatic transmissions are installed on the new generations of Toyota Camry. The first - for 2.4 liter engines, the second - for 3-liter engines. The weaker U140E is poorly adapted to the lower mass of the machine and, as a result, cannot boast of high reliability. A frequent breakdown on it is the failure of the back cover. This leads to burning of the clutches, slipping of the clutch, increased engine speed and breakdown.  Toyota Camry with a more powerful internal combustion engine is equipped with wear-resistant gearboxes that break less. However, there are also problems with the back cover. In addition, there are isolated cases of failure of the control electronics.

Toyota Camry with a more powerful internal combustion engine is equipped with wear-resistant gearboxes that break less. However, there are also problems with the back cover. In addition, there are isolated cases of failure of the control electronics.

Conclusion

As you can see, there are a lot of automatic transmission malfunctions, and although they are often of the same type, this does not mean that you should ignore the incomprehensible and non-standard behavior of the transmission. Never put off finding out the reasons "for later." Replacing an automatic transmission (Toyota Camry is no exception) can result in very a large sum. Therefore, it is important to keep the technical condition of this unit in good condition and carry out regular maintenance. After every 150 thousand kilometers, the box must be completely washed. This is done on a specialized stand, under pressure. This is the only way to remove wear and metal chips.

There is a very simple rule: "a serviceable car does not make extraneous noise." If the rule is violated, it is time to send the car for diagnostics to a technical center. This article lists common faults in an automatic transmission (AT) cars, as well as their signs.

The constant howling of the “box” on a stationary car, as well as sound changes depending on engine speed, indicates a low oil level in the automatic transmission and the following oil pump malfunctions:

Air has entered the pump (rings and seals have worn out);

Damaged oil pump gears;

The disassembly of the pump was carried out by a non-specialist who assembled the parts incorrectly.

If the sealing gland is worn out or broken, then an annoying buzz will be heard from the automatic transmission (it changes depending on the engine speed). The same sound will be when the spool of the valve that regulates the linear oil pressure vibrates.

Does the car start to slip on a long hill at the last speed? You need to check the oil level in the transmission. Lack of fluid leads to premature downshifting.

Signs of a torque converter malfunction are easy to identify by the characteristic "melodies" in the transmission.

When a sound is heard from the automatic transmission side, similar to a quiet siren, then there is a problem in the torque converter. Separately, it must be noted that the same sound during the parking test of a gearbox malfunction (stall speed test) does not give any cause for concern.

Worn torque converter springs cause a chronic rattling sound at low engine speeds. The second possible cause of rattling is the failure of the turbine pump blades.

Here are a few more signs of a bad torque converter:

There is no movement back or forward;

When switching from position "P" or "N" to any speed, the car slips and does not move;

There is no perceptible push to engage any gear;

There is no main pressure.

If the friction discs of the forward clutch or the piston collar of this clutch break, wear or break, the car will begin to slip in place. At the same time, if the reverse gear works, then the switching valve from 1st to 2nd speed is jammed, but if there is no reverse gear either, then the spline connection is cut off in the sun gear drum housing

Automatic transmission, by the way, will help determine the malfunction of the engine flywheel. If the engine has a defective flywheel, then when driving at low speeds, a rattling intermittent sound will come from the gearbox side. When shifting to neutral speed, the sound a short time disappears. However, when the sound changes its tone during the transition to other gears, the liners or thrust bearings are most likely worn out.

Symptoms various kinds and automatic transmission types are quite similar for different brands, most of them are listed below:

SYMPTOM

There is no forward movement, the car is stalling in place. Reverse speed is ok

CAUSE OF THE FAILURE

1. Wear of the friction discs of the forward clutch C 1.

2. Wear or breakage of the cuffs of the piston of this coupling.

3. Wear or breakage of the oil sealing rings of this coupling.

4. Stuck switching valve from 1st to 2nd speed.

SYMPTOM

There is no reverse movement, there is a 1st and 2nd speed forward, there is no 3rd speed.

CAUSE OF THE FAILURE

1. Wear of the friction discs of the forward clutch C2.

2. Wear or breakage of the cuffs of the piston of this coupling.

3. Wear or breakage of oil sealing rings, this coupling.

4. Sheared spline connection in sun gear drum housing.

SYMPTOM

There is no movement back, there are all shifts forward.

CAUSE OF THE FAILURE

1. Wear of the friction layer on the brake band.

2. Wear or breakage of the brake band piston cuffs.

3. The piston rod of the brake band broke.

SYMPTOM

There is no forward or backward movement, when shifting from "P" or "N" to any speed, there is no perceptible push into any gear.

CAUSE OF THE FAILURE

2. The drive gear of the oil pump has broken and does not work, it has moved away and there is no clutch with the torque converter

3. A small amount of oil in the machine.

4. The filter mesh is very dirty.

5. Strong wear of the friction discs of the clutches and the brake band.

6. Wear or breakage of the cuffs of the pistons of these couplings.

7. Worn or broken oil o-rings on these couplings.

8. 1st speed switch stuck.

SYMPTOM

There is no movement either back or forward, when switching to the “P” or “N” position at any speed, there is a noticeable push into gear, but the car slips and does not move.

CAUSE OF THE FAILURE

1. Defective torque converter.

2. A small amount of oil in the machine.

3. The oil filter mesh is dirty.

SYMPTOM

There is a movement back, and only 1st gear is engaged forward.

CAUSE OF THE FAILURE

1. Stuck control valve in centrifugal derailleur.

2. The helical gear on the speed selector shaft has broken.

3. Sheared the cotter pin of the helical gear on the switch shaft.

4. Stuck shift valve from 1st to 2nd gear.

SYMPTOM

There is a movement back, but only 1st and 2nd gears are engaged forward, there is no 3rd gear.

CAUSE OF THE FAILURE

1. Stuck 3rd speed enable valve in valve train.

SYMPTOM

The vehicle drives normally, but on a long hill at the last speed, slip occurs and downshifts prematurely.

CAUSE OF THE FAILURE

1. Low oil level in the machine.

2. Less wear on cuffs, sealing rings and discs of this clutch.

SYMPTOM

When starting off, the car slips a little, but after gaining a small speed it goes normally, switching to other speeds.

CAUSE OF THE FAILURE

1. In the torque converter, there is a lot of wear on the splines of the turbine wheel hub, which causes slippage of the gearbox shaft when high speed engine.

2. Wear on the friction discs of the forward clutch.

3. Worn or torn cuffs of the piston of this clutch.

SYMPTOM

The vehicle moves when the shift lever is in the "N" position.

CAUSE OF THE FAILURE

1. Adjustment of a cable or the lever of a drive of management of a transmission is broken.

2. Clutch piston seizure C 1.

3. Due to prolonged slipping, the discs were welded to the plates in the C 1 clutch.

SYMPTOM

Gear shifting occurs at speeds above normal values.

CAUSE OF THE FAILURE

1. The adjustment of the throttle valve control cable is broken.

2. Stuck centrifugal governor valve.

3. Partial clogging of the filter mesh.

4. Throttle valve stuck in the valve train.

SYMPTOM

At hard pressing there is no downshift on the gas pedal (kick-down effect).

CAUSE OF THE FAILURE

1. Faulty pressure sensor or kick-down foot switch.

2. 3rd to 2nd shift control valve sticking.

Z. Break in the electrical circuit of the sensor or foot switch.

4. Incorrectly adjusted throttle cable.

SYMPTOM

There is no engine braking in 1st and 2nd gear.

CAUSE OF THE FAILURE

1. The brake band of the 2nd gear brake has failed during engine braking.

2. Wear or rupture of the tape piston seals.

Z. Stuck modulating valve during engine braking.

SYMPTOM

Clutch slip when shifting gears.

CAUSE OF THE FAILURE

1. Medium clogging of the filter mesh.

2. Low oil level.

Z. Clutch C1 is defective.

SYMPTOM

There is no movement in "D" there is only 1, 2 and reverse gear.

CAUSE OF THE FAILURE

1. Wear on the friction discs of the forward clutch C1.

SYMPTOM

No shift to 3rd gear. Reverse rides fine.

CAUSE OF THE FAILURE

1. The oil seal rings in the centrifugal governor were worn out.

2. Valve sticking in the centrifugal regulator.

SYMPTOM

No shift to 3rd gear. At high acceleration, the transmission sometimes turns on.

CAUSE OF THE FAILURE

1. Large wear of the oil sealing rings of the 3rd gear clutch.

SYMPTOM

The car jerks while driving.

CAUSE OF THE FAILURE

1. The freewheel F1 is out of order.

SYMPTOM

Shifting gears in the machine occurs with tangible shocks, and not jerks as before.

CAUSE OF THE FAILURE

1. General wear of the friction discs of all clutches and brakes. In this regard, large gaps were formed in the sets of disks and plates.

SYMPTOM

There is no movement back or forward. There is main pressure in the machine.

CAUSE OF THE FAILURE

1. Cut the splines in the hub of the turbine wheel.

SYMPTOM

There is no movement back or forward. There is no main pressure.

CAUSE OF THE FAILURE

1. Cut off the splines of the oil pump shaft in the housing of the front cover of the torque converter.

The gearbox and torque converter are designed to transfer combustion energy from the engine to rear wheels. The gearbox transmits this energy through sequential shifting that starts low and ends high. Separate reverse gear allows you to move backward.

The torque converter serves as a fluid interface between the engine and transmission, allowing gradual and smooth force rather than sudden pressure on the transmission. Both nodes have their own problems, and if you know what to look for, you can avoid costly repairs.

Transmission malfunctions

1. Check if the light is on "check engine". If it is on, then you need to check with a scanner exact code malfunctions. This will help determine if the problem is related to the transmission. If the car is equipped with a separate overdrive indicator, then this will immediately allow you to find out where the cause is.

2. Use the code scanner to read all readings from the solenoid and sensors. The electronic transmission uses speed sensors to shift gears. If they are faulty or late, the gear sequence may be broken, and the box may default to second or third gear.

3. Start driving using slow sequential shifting and listen carefully as the gear changes. At the time, when the speed reaches 70-80 km/h, the box should reach the top gear without bumps and gaps.

4. look, Are there any transmission fluid leaks? in a box or around. Check the base of the filler tube for seal leaks. Check the transmission tailshaft for leaks and the casing containing the input shaft gaskets. If liquid builds up on the floor overnight, this may be an indication that the gaskets or seals are worn out. All transmission pan bolts must be in place and tight.

5. Check the transmission fluid level with a dipstick when the engine is warm. The level should be in the "hot" section. If it is lower or not visible, it means that transmission fluid needs to be added. Low level transmission fluid can cause sticky transmission, or the vehicle will not move when changing gears. sticking on high speed usually happens when you press the gas pedal hard and the car does not change gear, the engine revs up and the gearbox is not engaged.

6. Check transmission fluid. If it is cloudy, blistered or discolored, this means that the fluid is corrupted and the pump will not work properly. Old fluid or fluid that is dirty brown and has a burnt odor is unusable.

Torque Converter Malfunction Identification

*Listen whether there are any noises when the transmission is involved. If the noise disappears when the neutral gear is engaged, it is possible worn bearings torque converter, causing excessive movement and misalignment of parts. Needle bearings separate three important components of the torque converter, if the bearings wear out, it will affect the performance of the torque converter as a whole.

* Switch the car to accelerate, then to the neutral position, then to the rear, and then listen for any clicking sound. These sounds usually indicate that torque converter damaged. This usually happens when the clamps wear out or the fasteners between the torque converter and the flywheel are broken.

* Drive a car at speed, and then gradually reduce the speed to a complete stop, noting each flinch or jerk. They may indicate bad solenoid mount or sticky valve. These jerks can also result in unnecessary vibration and indicate that the torque converter is being overloaded. When the torque converter or transmission is faulty, the vehicle may make howling sounds.

* Check for transmission fluid in the drain hole at the bottom of the casing. A broken torque converter will leak fluid through a small hole designed to check for drainage, and may also smell like burnt, whereas transmission fluid will be dirty brown.

Unfortunately, the availability of all kinds of information on the Internet about various breakdowns, including automatic transmission malfunctions, will not help you fix the breakdown yourself. That is why it is strongly not recommended to resort to "self-treatment", because the machine, like the human body, needs, first of all, high-quality professional help.

Questions regarding the diagnosis of automatic transmission malfunctions are also not recommended to be asked on the Internet or by phone, as soon as slippage has been detected, you must immediately contact a good service with highly qualified auto repair specialists.

One of the main reasons for the impossibility of independent “treatment” of automatic transmissions is that in order to determine the breakdown, it is necessary to carry out computer diagnostics of automatic transmissions and only after that prescribe “treatment”. Only a master can make a really high-quality assessment of the condition of your car and proceed with subsequent repairs.

Diagnosis of automatic transmission can be divided into the following stages:

- The stage of installing visible and, most importantly, audible problems. This is the first and fastest type of diagnosis of automatic transmission malfunctions, which the owner of the car is able to make himself and, based on assumptions about malfunctions, contact a specialist.

- The stage of the average level of complexity, the so-called tangible . This diagnosis can only be made by the master, since it consists directly in removing codes, various autotests, followed by the installation of a “diagnosis”.

- The stage of repair, which is resorted to after the first two stages . It begins after the slip has been diagnosed and can ONLY be carried out by a highly qualified automatic transmission repairman. Otherwise, you can completely ruin your car and significantly increase the possible costs of its repair. This stage is most often necessary when the car is already in a deplorable state (driving in 3rd gear) or slipping of the clutches is observed. In all of the above cases, disassembly of the automatic transmission is necessary. Only this procedure will help you determine with 100% accuracy both the type of breakdown and the method of repairing it.

How to understand that your car is slipping?

If you begin to notice that your car, while in motion, seems to be slipping part of the road, or if you hear that the engine of your car starts to idle when you shift to a higher gear, then you are experiencing slippage. One of the main reasons for the appearance of slippage when switching to increased is considered to be the use of low-quality transmission oil for your car. If the reason that your car is slipping when switching is poor quality, then the solution to the problem will be to replace parts such as the air filter and directly change the oil itself. But it should be remembered that such a simple solution can only help with a slight slip when switching. In all other cases, a rather long and laborious repair of your automatic transmission will be inevitable. If the car slips only when switching to a cold one, then you should check the clutches.

Also, if your car is slipping in the cold, then you need to check the oil level. If the oil is below normal, then you have found the cause of the problem, as well as its solution. If you filled in oil, but the car still slips in the cold, then there is a chance that it's time to replace the clutch.

But in order to be completely sure that the slip on the cold appeared precisely for this reason, it is necessary to contact a qualified specialist with extensive experience in solving such issues.

It may also be the case when the car behaves normally when switching to a cold car, and slips when switching to a hot one. In this case, everything is much more serious and an independent solution, or rather, trying this solution can cost you quite a bit. a large amount. To properly fix the problem of slipping a car with an automatic transmission on a hot one, you must immediately contact a good, proven service.

Also, one of the most common problems is considered to be slipping of the car when shifting gears. Most often this indicates a malfunction. However, this theory can be verified for reliability only through computer diagnostics of the car, and therefore an independent solution to this problem is impossible.

If your car is slipping when starting off, then most likely your air filter is clogged. This is a fairly common and quite easily fixable problem.

What's more, slip when starting off is one of the few automatic transmission problems that you can replace yourself with minimal knowledge in the field of car repair. To eliminate this problem, it is enough to replace (just replace, not clean) the air filter.

Causes of car slip

Above, we described the main reasons why a car with automatic transmission slips, and now let's look at each of them in more detail.

Hydroblock

As mentioned above, valve body malfunctions can quite often cause a car with automatic transmission to slip. Such malfunctions most often become clogged channels of the valve body itself. With such a problem, lubrication key elements Automatic transmission is not provided, and therefore slippage of the clutch is observed. With such a problem, as mentioned earlier, the solution is quite simple - cleaning these very channels or replacing the air filter of your car. The valve body can be cleaned only in a special service, which is equipped with everything necessary equipment. also in Lately this type of valve body cleaning has become popular, such as cleaning with special compounds or using ultrasound.

The modern auto repair industry with completely new technologies in solving such problems can almost completely eliminate clogged channels and avoid replacing the valve body. However, this is a rather time-consuming procedure that occurs directly with the dismantling of the valve body itself, and it may take several days to complete it.

If you contacted a car service with problems regarding the valve body, then you need to remember that after the repair of the valve body, it is necessary to replace all the filter elements of your car, as well as change the oil itself directly in the gearbox.

In almost any operation with the dismantling of the valve body, the solenoids are replaced in parallel.

This is due to the fact that the solenoids quickly become unusable, especially if you use old or low quality oil. Before replacing the solenoids, the master measures the pressure directly in the lubrication system. This simple procedure for an experienced professional allows you to detect certain problems related to the solenoids. If the pressure in the lubrication system is quite low (most often this is accompanied by slipping of your car on a hot one), then this almost always indicates certain malfunctions related directly to the solenoids or the pump.

If such a problem is detected, all failed elements are directly replaced, after which the performance of your transmission will again be carried out on highest level. It is also necessary to replace the solenoids with so-called solenoid packs. Such a precaution will significantly reduce the repetition of this breakdown and extend the life of both the automatic transmission and the car itself.

Also, after performing all the above steps, many auto repair services carry out clutch diagnostics in order to completely eliminate the possibility of your car slipping. This is due to the fact that the clutches themselves are short-lived, wear out quickly enough and subsequently become completely unusable. Normal numbers for clutch wear are considered to be 250–300 tkm. Most often, it is at this border that friction clutches wear out with the need for their subsequent replacement. The work itself is very complex and time-consuming, which does not allow it to be done at home.

ECU automatic transmission (Electronic control unit)

The last of the options possible causes slippage of a car with automatic transmission is considered to be the incorrect operation of the transmission control unit. With this problem, a so-called malfunction of the computer occurs, which leads to the fact that your car is slipping. With this type of problem, the only possible solution may be to completely replace the electronic control unit itself. Diagnosis of this problem is quite simple, but in most cases it is not possible to carry it out on your own. The cost of such work varies greatly, which is explained by differences in the cost of the cars themselves with automatic transmission. Despite the fact that the work of replacing the electronic control unit itself is quite simple, its implementation at home is strictly unacceptable.

Thus, we have considered the main reasons why a car with automatic transmission is slipping. Despite the apparent simplicity of the work to eliminate certain malfunctions that caused the car to slip, it is highly not recommended to engage in self-repair of the car. Otherwise, you run the risk of completely ruining the car itself or spending a much larger amount on its repair.