Front wheel drive differential. How differentials work. Video: GPS Navigator - description and test.

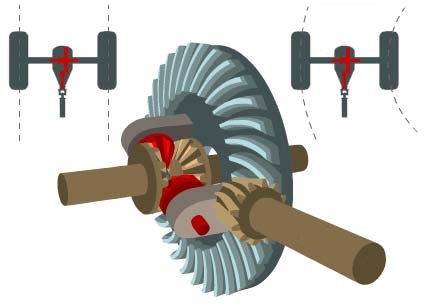

The differential is designed to transmit, change and distribute torque between two consumers and ensure, if necessary, their rotation at different angular speeds.

The differential is one of the main structural elements of the transmission. The location of the differential in the transmission of the car:

The differential is something more complex, not taking into account the already existing variety, from mechanics to electronics. Based on a car with single axle traction, both rear and front, we can find from an open differential to an electronic one, passing through a self-locking, torzen or self-locking electron.

Video: Differential lock for UAZ, type and principle of operation

When we travel in a straight line, that is, both wheels move at the same distance, the differential formed by the different gears keeps the latter at an equal speed. When you enter a curve, the outer wheel, on which the car stands, travels more meters than the inner one. That's why there is a differential. This mechanism, as we said earlier, distributes the power of the engine between the wheels, allowing them to move at different speeds.

The differentials used to drive the drive wheels are called cross-axle. The center differential is installed between the drive axles of an all-wheel drive vehicle.

Structurally, the differential is built on the basis of a planetary gearbox. Depending on the type of gear used in the gearbox, the following types of differentials are distinguished: bevel, cylindrical and worm.

The vast majority of street cars, without becoming sporty, have famous open differentials. When the curve is reached, the outer wheel receives little engine power as the differential sends most of it to the inner wheel with less support due to the object that has to arrive there.

How the differential works

Under normal conditions, this is not a problem, but when driving fast, whether on a contour or on a curved road, the inner wheel, if we do not have traction and stability control, can end up spinning out of control, leading to slip or loss with the consequences that this entails. behind you.

The bevel differential is mainly used as a cross-axle differential. Cylindrical differential is installed more often between the axles of all-wheel drive vehicles. The worm differential, due to its versatility, can be installed both between the wheels and between the axles.

The device of the differential is considered on the example of the most common conical differential. The components of the differential are also characteristic of other types of differentials. The bevel differential is a planetary gearbox and includes side gears with satellites placed in the housing.

His work, like the rest, focuses on curves. Thus, the step-by-curve is markedly increased. True sports have such differences, although in last years they have become fashionable, mainly due to the ease of controlling them through a computer, electronic differentials.

Between half of the two types described above are the well-known Thorsen-type differentials. They bring an important advantage over other systems. It's not a differential, definitely self-locking as it can't be fully locked, but it sends torque to the wheel which can the best way send it to the ground. Faced with a self-locking differential, Thorsen avoids slipping one of the wheels, contributing only to what he can send to the ground, diverting the surplus to the other.

The housing (another name is the differential cup) perceives the torque from the main gear and transmits it through the satellites to the side gears. The driven gear is rigidly fixed on the body main gear. Axes are installed inside the case, on which the satellites rotate.

Satellites, playing the role of a planetary gear, provide a connection between the housing and side gears. Depending on the amount of transmitted torque, two or four satellites are used in the differential design. IN cars usually two satellites are used.

We will take a detailed look at the different types of differentials and the most commonly used vehicles you can find on the market, as well as their advantages and disadvantages. This system, which ensures that two wheels attached to the same axle rotate at different speeds, has achieved since its introduction that the number of accidents is reduced and there is less tire wear for all vehicles.

differential operation

The differential is a system that allows you to better grip the movable wheels on curves. That is, when we take a curve, the wheel that gives the outside moves a greater distance. The differential allows you to adapt the speed of each wheel depending on whether it is in the inner or outer zone. Otherwise, the car will drift. Interestingly, drifting vehicles avoid this system so that both wheels always spin at the same speed.

Side gears (sun gears) transmit torque to the drive wheels through axle shafts with which they are splined. The right and left side gears can have equal or different number teeth. Gears with an equal number of teeth form a symmetrical differential, while an unequal number of teeth is characteristic of an asymmetrical differential.

Types of self-locking differentials

The self-locking differential is the most widely used system, although electronic systems have nearly replaced them because they do their job with sensors rather than self-lockers. At present this system is much used in competition vehicles, although until a few years ago they were used in a conventional way.

differential differential

These systems are widely used in racing cars, usually in rear wheel drive. Due to the high forces certain cars play with, they need to turn on this system as it usually has traction losses and it is very important to control traction using a series of friction discs that distribute power to the shape wheels in a consistent manner.

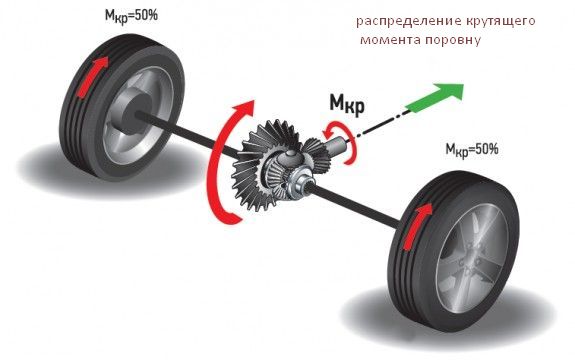

A symmetrical differential distributes the torque along the axles in equal proportions, regardless of the magnitude of the angular speeds of the drive wheels. Due to these properties, a symmetrical differential is used as a cross-axle differential.

An asymmetric differential divides the torque in a certain ratio, therefore it is installed between the driving axles of the car.

Friction disc self-locking

Although several types are used, this is without a doubt the most common of the mechanical self-locks. This system has separate disks that intersect between them.

Viscous differential or Ferguson

These differentials are characterized by having a casing on the transmission shaft that covers the discs, intercalates with each other, or is also included in the gearbox at present. His work is based on a kind of oil mixed with silicone. When the shaft loses traction, the temperature of this lubricant increases, as well as its pressure, thereby achieving complete coverage of the discs.Differential operation

In the operation of a symmetrical cross-axle differential, three characteristic modes can be distinguished:

- rectilinear movement;

- movement in a turn;

- driving on a slippery road.

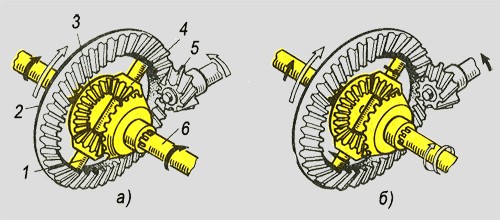

At rectilinear motion wheels meet equal resistance of the road. The torque from the main gear is transmitted to the differential case, with which the satellites move. The satellites, running around the side gears, transmit torque to the drive wheels in equal proportions. Since the satellites on the axles do not rotate, the side gears move at the same angular speed. In this case, the rotational speed of each of the gears is equal to the rotational speed of the main gear driven gear.

In this action, a harmonic lock is achieved depending on the attention required by each wheel. This is a very common system in 4×4 vehicles as it is a cheap and compact system, and allows a differential to be distributed with two transfer shafts, one for each axle.

The main problem they present is that there are times when the total traction is only activated when sliding surfaces are present, but under normal circumstances acts as a rear or front wheel drive. In this system we also find an alternative for viscose. This is when we use a normal differential, performing the basic function of locking the four wheels when needed, with the difference that the action allows traction to be maintained on the four wheels of a constant shape, while eliminating the dual mode traction problem that the Normal viscous system presents.

When cornering, the inner drive wheel (located closer to the center of the turn) encounters more resistance than the outer wheel. The inner side gear slows down and causes the pinion gears to rotate around their axis, which in turn increase the speed of the outer side gear. The movement of the drive wheels with different angular speeds allows you to turn without slipping. At the same time, the sum of the rotational speeds of the inner and outer side gears is always equal to twice the rotational speed of the driven gear of the final drive. Torque, regardless of the different angular speeds, is distributed to the drive wheels in equal proportions.

Unlike previous models, its operation is more complete and efficient. That is, instead of distributing the rotation of each wheel depending on the speed at which it circulates on the curve, this system performs the function of resistance, which opposes each axle for that turn.

The distribution between the wheels is more characteristic of the conditions in which it is driven. Its operation is controlled by three pairs of helical wheels which function as a worm gear mechanism. That is, they move as if they were guided by a straight line. Basically, when the car takes a curve, these axles turn on themselves, depending on the turn, one axle turns more and the opposite one slows down, since the opposite one, which rotates faster, causes this reaction at the moment of sliding.

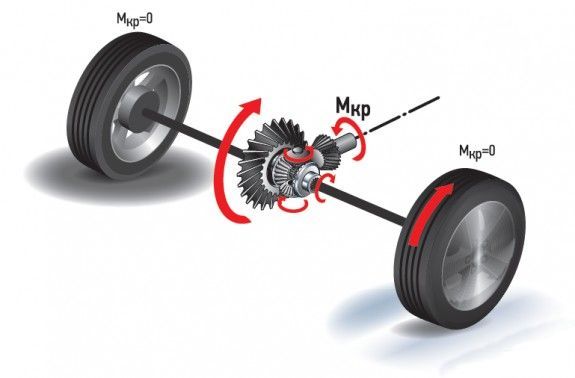

When driving on a slippery road, one of the wheels encounters more resistance, while the other slips - slips. The differential, by virtue of its design, causes the spinning wheel to rotate at an increasing speed. The other wheel then stops. The traction force on the slipping wheel, due to the low grip force, is small, therefore, the torque on this wheel is also small. And since we have a symmetrical differential, the torque on the other wheel will also be small. Deadlock - the car cannot move.

Another advantage of this system lies not only in acceleration, but also in braking moments. Very important fact, because in many cases when braking, whether on a curve or on uneven roads, this system brings more braking torque to the wheel it needs most, whether on the left or on the right.

Differentials with self-locking

This makes your traction status readings more efficient. These systems offer several amenities that make it a great product to use between different systems. The comfort is not comparable to one of the limited misses. In addition, it supports a more stable vehicle by offering directional control to better control the route. On the contrary, the only drawbacks they bring is that breakdowns can be more severe and, in fact, they are more expensive.

To continue driving, it is necessary to increase the torque on the free wheel. This is done using

Let's start with what this automotive technical term itself means in an accessible way. ordinary person language. An automobile differential is what makes up the transmission and what makes it possible for the wheels to spin asynchronously, that is, each wheel is independent of each other and rotates separately.

Controlled slip differential

In fact, they are also known as couplings or multi-disc connectors. Their task is carried out by means of a pack of conductive discs compressed by a hydraulic system. That is, its mechanism is very similar to the clutch mechanism. Thus, by necessity, the clutch acts more on one wheel than the other. A system in which, under normal conditions, unlike the torso, it works like front-wheel drive. However, in extreme situations, the transmission will push engine power to the rear wheels.

In scientific terms, (from Latin differentia - difference, difference) a car differential is a device that divides the incoming energy (torque) supplied to the input shaft between the output shafts. A simple and understandable explanation expands horizons. Girls are also interested in the work of machine mechanisms.

Structural differences of friction clutches

Integral traction refers to constant traction on all four wheels. The center differential is installed in the transfer case and its function is to act on the curves that transmit torque and different speeds for front and rear axles.

This is what a modern Torsen differential looks like

Note that on the curve, each axis moves a different distance, and some resource must take action to compensate for this difference. When the front axle starts a curve, it will offer less resistance while developing more high speed, and there will be more torque through the center differential than the rear axle.

Reason for use in car designs

During the turn of the car, the driving drive wheels rotate at the same speed and as one wheel of the car makes a turn in a long arc, and the other in a short one, slip occurs, which has a bad effect and is accompanied by tire wear and causes discomfort to the driver due to a decrease in quality car dynamics.

But the center differential works all the time, and in off-road situations, it transfers all the torque to the axle, in which the wheel rotates freely without contact with the ground. The center diff will leave the axle with traction conditions without torque and transfer everything to the axle that has the slip wheel. This axle, in turn, will have its own differential, which takes off the torque of the wheel with traction, transferring everything to the wheel, which rotates in the air. The result is a stationary vehicle with no conditions to move forward.

Purpose of the differential

- allows the drive (driving) wheels to rotate at different angular speeds

- serves as a separate additional gear paired with the main gear. The main gear is a gear mechanism of a car transmission that transmits torque to the drive wheels.

- continuously transmits torque from the engine to the drive wheels.

In front-wheel drive cars, the main gear and differencial are located directly in the gearbox.

In front-wheel drive cars, the main gear and differencial are located directly in the gearbox.

This will allow you to use more conditions traction on low friction terrain such as mud, sand, loose rocks, steep slopes, slopes with steep slopes and grooves and erosion. To disengage the lock, stop the vehicle and turn off the key on the dashboard or move the lever to the previous position. If the lever stops or the chain is still active, turn back a few meters after the key is turned off when the system disengages without further problems.

Central locking is extremely important for most off-road situations. But never forget that you should never use them in situations where there is total friction with the ground, such as asphalt, concrete and dirt roads with hard soil, because the vehicle cannot make curves as easily as a center differential. the risk of damage to the gearbox, moreover, makes it difficult to perform curves.

If more than one engine is installed on the vehicle, one engine per wheel, then the differential is not required. But they don't usually do that. Install 4 engines, one for each wheel, only on Belaz dump trucks. These motors are electric.

In the device of racing karts, a differential is also not installed, since the frame design is flexible, which allows you to slightly raise the rear drive wheel from the inside of the turn without lifting the front wheels.

in figure a) - the wheels rotate at the same frequency, in figure b) - the movement of the wheels on a turn

1 - axis of satellites, 2 - driven gear, 3 - side gears, 4 - satellite,

5 - drive gear, 6 - axle shafts.

On racing cars, differencial rallies are usually welded, hard-blocked, and tightly tied to the wheels on the drive axle. This is used because such cars when driving, all turns pass with a skid.

How the differential works

Operating principle. The main gear transmits torsional energy through the gear to the housing and satellites, which are engaged with the gears of the axle shafts.

When the speed of rotation of the wheels is the same, the satellites sit motionless (see pictures below).

When the angular speeds of the wheels change, for example, when turning or slipping due to uneven roads, and so on, the satellites rotate. Satellites are used to compensate for the difference in wheel speeds.

Consider an example - a car slips on ice. Here, one wheel is slipping, because there is no grip on the ice, which means there is no torque. And since the free blocking device distributes traction equally to the wheels, if there is no torque on one wheel, then it disappears on the second.

The way out of this situation is to create an opposing force on the opposite wheel. And that's what blocking does. It is necessary to block the slipping opposite wheel and then there will be an opposing force for the opposite wheel.

How a differential works on a four wheel drive vehicle

On jeeps, sedans, hatchbacks and station wagons 4x4, if a free symmetrical differential is installed, the following situation occurs. While driving without slipping, 25% of the torque energy is distributed equally to each wheel.

But if one wheel is slipping, for example on ice, the torsional energy is reduced to zero because the wheel cannot grip the smooth surface of the ice. In such a situation, if one wheel is left without rotation, then the energy of rotation disappears on the opposite adjacent wheel, because in this example installed symmetrical center.

But if one wheel is slipping, for example on ice, the torsional energy is reduced to zero because the wheel cannot grip the smooth surface of the ice. In such a situation, if one wheel is left without rotation, then the energy of rotation disappears on the opposite adjacent wheel, because in this example installed symmetrical center.

It turns out that one axis was left without rotation, and therefore the torque on the second axis also disappears, since the differencial center axle is symmetrical. The result is no rotation on all 4 drive wheels.

Next is what we do. We block the interaxle symmetrical differential, which results in a rigid connection between the axles. Since the front wheels are not spinning, the rotational energy is distributed in half on rear wheels by 50%.

Next is what we do. We block the interaxle symmetrical differential, which results in a rigid connection between the axles. Since the front wheels are not spinning, the rotational energy is distributed in half on rear wheels by 50%.

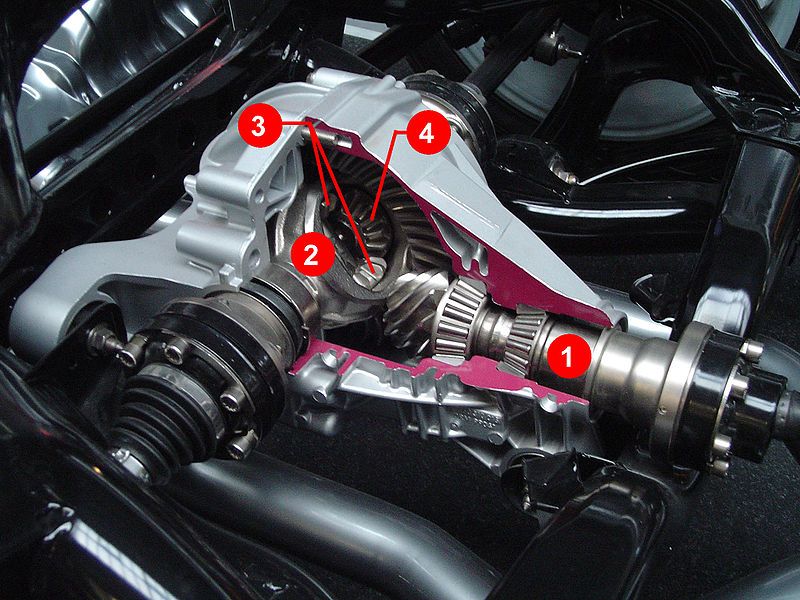

Sectional drawing-differential. Main gear and differential of a rear-wheel drive car:

1 - crankcase; 2 - cover; 3 - protective cover; 4 - retaining ring; 5 - axle shaft; 6 - bearing seal; 7 - adjusting nut; 8 - bearing cup; 9 - side gear; 10 - differential box cover; 11 - driven gear of the main gear; 12 - retaining ring of the pin of the satellites; 13 - finger satellites; 14 - satellite; 15 - device box