Fluid coupling of the cooling fan gas principle of operation. Viscous clutch, UAZ cooling fan

Greetings to all owners of foreign cars that have a radiator cooling fan with a viscous coupling installed under the hood instead of an electric fan - this article is for you. When this part stops working properly over time and the engine starts to overheat, many drivers have no idea what to do with it. Many not rich drivers, having entered the store and found out its price (from $ 150 and above), try to repair their viscous coupling, but after disassembling it, they simply understand that they cannot afford to restore it, and, like most drivers, they begin to claim that it not repairable. But in this article, we will nevertheless prove the opposite, and we will also prove that with a skillful approach and the necessary knowledge, EVERYTHING can be repaired.

The name of the viscous coupling.

Let's start with the simplest - with the name of the viscous coupling. Most drivers who tried to repair this part probably never thought about the name of the part, but in vain. The name itself speaks for itself - viscous coupling, the name confirms that such a clutch is a device that transmits rotation to the fan due to the friction force (viscosity) of a special viscous liquid, placed between two disks - master and slave. The drive disk is attached to the engine shaft (more precisely, to the pump pulley), and the radiator cooling fan itself is fixed on the driven disk. All this is assembled into a case and supplemented with a few details, but more on that later.

And the whole process of the normal operation of the viscous coupling is to glue these disks (so that the fan starts to rotate at high speed) at the moment when the engine temperature begins to rise above normal, and glue the disks (master and slave) when the engine temperature is lowered below normal operating temperature (slow fan rotation). I think everyone understands this simple principle of operation, and we will gradually move on to the details.

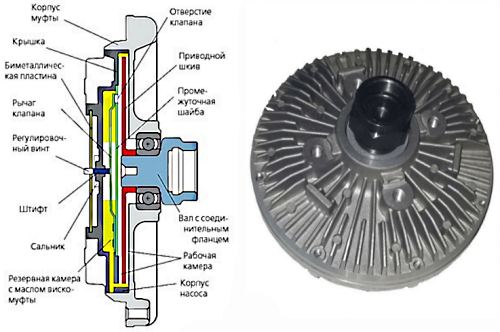

Clutch device.

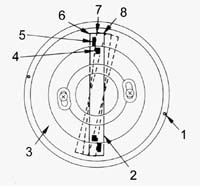

1 - plate on which the stem (valve) presses, 2 - locking plate in which there is a hole for the passage of liquid, 3 - bimetallic spiral, 4 - cover, 5 - bearing housing, 6 - drive disk, 7 - fluid reservoir. Rubber o-rings are shown in yellow.

Controls all of the above process, hot air, from a heated radiator. After all, the viscous coupling itself is fixed close to the radiator and for good reason. At its end, a bimetallic plate is fixed (more often with rivets), most often in the form of a spiral. When heated from the hot air of the radiator (after all, the plate is very close to the radiator), the plate begins to change its shape (bend), and changing shape it presses on a thin stem, and the stem presses on the plate valve (see photo below), which opens the hole, to get between the disks (master and slave) of a special viscous fluid, which increases friction between the disks and, as it were, glues them together. From this, the radiator fan, which was previously spinning slowly due to disk slippage, begins to rotate with high turnover and effectively cool the radiator, reducing the temperature of the coolant and, of course, the car's engine itself.

And the main reason for overheating of the car engine comes from the above, that is, if the engine overheats, then the fan speed is insufficient, and if the speed is insufficient, then this very viscous liquid is not enough to effectively glue both disks - master and slave. The liquid most often begins to come out (gradually) through a dried up sealing ring of the rod (shown in yellow in the sectional figure) located in the very center of the coupling, but under the bimetallic plate.

The plate valve of the viscous coupling, which is fixed on a round locking plate (disk) and this valve closes the opening for the passage of fluid.

To get to the sealing ring, it is necessary to carefully grind off one of the heads of two rivets from the sides (so that you can later rivet it back) that hold the bimetallic plate (but the plate on older machines, and on more recent ones it is in the form of a spiral). Next, remove the plate, and remove the stem with the ring. You can look for a new native ring, or you can pick it up from a repair kit of some kind of carburetor (by the way, sealing rings of any diameter are sold separately in our city).

Restoration of the normal operation of the viscous coupling.

Before returning the stem with a new sealing ring and the bimetallic plate to its place, it will naturally be necessary to replenish the spent liquid. This liquid is silicone based and very viscous (like epoxy glue). You can find it for sale at major cities and its marking may be different, depending on the manufacturer, one example of PMS is 100.

By the way, when the fan rotates and slips (when the motor has almost warmed up and the plate valve supplying liquid begins to open - it is shown in the photo on the left), the disks fidget back and forth between themselves, and the liquid that has begun to flow tends to glue the disks even better from this fidgeting, so How

It is rare that viscous couplings have a special filling hole, as a rule there is none. Some advise drilling a hole in the body, and then after pouring the liquid, tighten the screw on the thread lock there, you can do it like this (on which couplings I need to do this, I will write a little lower). But it's better not to add excess weight in the form of a screw, even one gram. After all, the fan speed is very large and an extra imbalance from the screw is undesirable. You just need to pour the liquid with a medical syringe through the stem hole. Of course, it will take much longer, because the hole is small, and the liquid is very viscous, but it will not be necessary to drill or cut anything.

On some cars, for example Mitsubishi, there are no rivets to remove the bimetallic spiral, and the rivet, the head of which needs to be ground off (only from the inside), is the stem itself (with two sealing rings) that pushes and opens the valve. It is much more difficult to disassemble such a coupling without damaging the stem, and in this case it is better to drill a hole in the body and cut a thread in it. The liquid will be poured through the threaded hole, and after filling, the screw is screwed on the thread sealant.

The viscous coupling is in the open state, and grooves are visible for draining fluid from the cavity (at speed).

By the way, when you disassemble the clutch, you will notice longitudinal grooves in the form of an impeller (see photo). These grooves are just what is needed so that when the engine of your car is not warmed up yet, and the liquid remains between the disks, and when the fan rotates, using centrifugal force, remove unnecessary fluid through these grooves. this moment liquid (so that the discs slip between each other and the fan rotates slowly while the car engine warms up). And if the clutch has already been disassembled, then check if there is any dirt inside and in the grooves, and if there is, then rinse all the parts and assemble.

I advise you to tighten the screws that fasten both halves of the coupling to the thread lock. We put the bimetallic spring in place, not forgetting to put the rod with a new sealing ring in its place. If you fail, fix the bimetal plate in its place, because it often happens that the head of the rivet deteriorates, then you have to go to any car service and ask Uncle Vasya to drop a drop of aluminum on the rivet and thus fix the plate.

After assembling and installing the viscous coupling in place, you should check its operation. This can be done with easy way: Roll a long roll of thick paper in advance, and then start your car engine. Until the motor is warm, place a paper roll under the rotating fan (take care of your hands, because all craftsmen have golden ones), and try to stop the rotating fan with a paper roll. I managed to do this - the fan was stopped, which means that everything is fine so far.

Now let the engine warm up well to operating temperature, and then again try to stop the fan impeller with a paper roll. If this cannot be done, then everything is in order and the valve has worked, letting in liquid between the disks and gluing them together, causing the fan to rotate without slipping, at the same speed as the pump shaft, and now it effectively cools the radiator, reducing the temperature of the motor. Overheating is excluded in this case. The repair has been successfully completed.

If someone finds such a repair difficult, and who does not want to bother with repairing the viscous coupling, or someone may not be able to repair it, then it will be possible to weld fasteners in the area of \u200b\u200bthe radiator fasteners, and fix an electric fan to these fasteners. But only in this case, it will also be necessary to fix the fan switch-on sensor in the radiator itself.

Until it's been repaired.

And finally, a couple of tips. Many drivers, especially in the outback, will not be able to immediately find or order silicone fluid to be brought, but it is very necessary to drive. Many "specialists" may advise drilling a hole between the two halves of the part and thus fix the fan impeller and prevent the motor from overheating. It is categorically impossible to do this, since the parts deteriorate (the tightness is broken) and if you manage to buy liquid, then it will no longer help - this is the first thing. And secondly, the iron bolt will simply cut off after a few hours of operation, and the parts will finally break and deteriorate, since jerks during fan operation are inevitable. The place of such a viscous coupling is only in a landfill.

Well, what to do if you still need to go, but there is no liquid? There is only one simple way to keep the details until the liquid is found. We disassemble the clutch and insert a cut-out circle of sheet rubber between the two disks, and then we tighten both halves. Only the rubber should not be too thick, otherwise, when tightening the halves of the coupling, you can bend the discs. That's all - now when the fan is running, you will have a soft (rubber) clutch between the disks, which excludes breakage of parts from jerks.

But I want to warn you that this is a temporary repair, because having fixed the fan impeller in this way, it will now rotate at high speed constantly, even when the engine is warming up. And that means the engine will warm up and go to operating temperature much slower, which is the same as having the thermostat open all the time (or no thermostat at all). It is not necessary to explain that this is not good and trips on a cold engine are harmful, and you can read more about this.

But I think that for any adequate driver, this will only be a temporary measure, and having bought a liquid, he will try to restore the normal operation of the viscous coupling, as I described in this article, or he will buy a new one - you choose; Good luck everyone!

In modern cars in the engine cooling system, electric drives of the radiator fan are used. On Russian roads, you can find cars equipped with a viscous coupling as a means of driving a radiator cooling fan.

Such couplings, due to design features, can only be installed on cars with a longitudinal engine installation, that is, with rear-wheel drive. Most cars now have front-wheel drive, so the viscous coupling in the engine cooling system can not be seen often.

Not every service station has specialists who know how to check the viscous coupling of a cooling fan for operability, perform its maintenance and repair.

The principle of operation of the viscous coupling of the cooling fan

This device is sometimes referred to as a "viscous coupling". Its rotor is connected to the engine crankshaft pulley by means of a belt drive. On some vehicles, it is mounted directly on the crankshaft or camshaft shaft.

The design of the viscous coupling has two disks located at a close distance from each other, but not mechanically connected to each other. They are located in a closed cavity. One of the disks is mechanically connected to the drive rotor and the crankshaft (camshaft). The other disk drives the fan impeller that cools the radiator. Since the disks are not mechanically connected in any way, theoretically the rotation of the engine will not be transmitted to the fan, it will be stationary.

Video - what is a viscous coupling and its principle of operation:

When the viscous coupling is heated, the geometric dimensions of the bimetallic plate, which is installed in it, change. It opens a channel for viscous gels or oils to enter the cavity where the disks are located, which, as the cavity fills, viscously binds the disks. For greater engagement, additional ribs or ridges are located on the discs, which increase the degree of engagement. Thus, a "viscous" engagement between the disks is provided, respectively, the engine torque is transferred to the radiator fan, and its cooling is ensured.

Video - how the viscous coupling of the cooling fan works:

As it cools, the gel is pumped out of the chamber under the action of centrifugal forces, and the viscous connection stops.

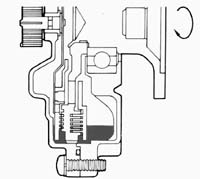

The typical design of a visco-sleeve, shown in the figure, makes it easier to understand the principle of its operation:

1 - spring;

2 - bimetallic plate;

3.4 - inlet channels B and A;

5 - camera;

6.7 - return channels;

8 - rear spring;

9 - front tank;

10.16 - rotors;

11 - body;

12 - rotor shaft;

13 - bearing housing;

14 - rear tank;

15 - rear plate;

17 - front plate;

18 - cover.

In general, the design is quite complex, so the cost of a new viscous coupling is high.

Video - what is inside the fan viscous coupling:

In some cases, if the viscous coupling malfunctions, which does not allow its restoration, in the absence of analogues, car owners are forced to convert the car to a system with an electric fan.

The main causes of the malfunction

If timely scheduled maintenance of the viscous coupling is carried out, its resource is at least 200,000 kilometers. Given that most of the cars on which such drives are installed have a solid mileage, the owners of these cars have encountered viscous coupling problems more than once.

The main reasons for the malfunction include:

- natural wear and tear;

- changing the parameters of bimetallic plates;

- bearing wear;

- beating of the fan impeller (partial destruction of the impeller);

- gel leakage, untimely refueling, change in the gel structure;

- mechanical damage.

Also, premature failure of work may be accompanied by clogging of the radiator cell airflow zone, contamination of the design of the coupling itself.

Symptoms

The main symptom of a viscous coupling failure is engine overheating. This happens mainly if the gel has leaked out, or the bimetallic plate does not work at the right time. In this case, when the engine temperature rises, the fan does not start to rotate or rotates at low speed, not providing normal cooling of the radiator.

The reverse malfunction, when the fan starts to rotate on a cold engine, often occurs when the physical parameters of the gel change, numerous viscous coupling units fail, and the lubricant solidifies.

Advantages and disadvantages

A cooling system malfunction is a critical vehicle malfunction, in which further independent movement cannot be continued. Therefore, the main consumer characteristic of a viscous coupling is reliability. From this position, it is higher than in the case of an electric radiator fan.

Many car owners are familiar with the problem when, after the winter season, they have to repair the electric drives of the radiator fans, the electronic circuit for controlling the engine cooling system. There are no electrics and electronics in the viscous coupling system, this is a big plus.

Video - replacing a viscous coupling with an UAZ Patriot electric fan:

Another advantage of the viscous coupling is the high power it can provide on the fan shaft. Theoretically, this power can be equal to the entire power on the shaft of the internal combustion engine, that is, several kilowatts. The electric motors of the radiator fans of passenger cars have a power of the order of several tens of watts. Therefore, in a powerful agricultural, construction, military equipment have not yet abandoned the use of viscous coupling.

Disadvantages of viscous coupling:

- the complexity of the technical performance, the difficulty of repair, it is easier and cheaper to replace it as an aggregate (entirely);

- has a large mass, exerts a mechanical load on the shaft;

- control of the temperature of its inclusion does not have sufficient accuracy;

- increased noise in high revs engine;

- when carrying out routine maintenance, it is necessary to refuel (refill) the viscous coupling with gel or oil of a certain viscosity, such specifications difficult to find in reference books;

- additional engine power take-off.

These and other shortcomings have practically replaced viscous couplings from the cooling systems of internal combustion engines of passenger cars.

Restoring the performance of the engine cooling system

In case of failure of the viscous coupling, first of all, it should be refueled with oil or gel. There are no exact recommendations on this matter, usually you have to experiment.

You can try to find narrow specialists, but it’s easier and cheaper to find a used one for disassembly. If the search for a working viscous coupling is unsuccessful, you can think about replacing the cooling system with a conventional, electrically driven one.

Video - replacing a viscous coupling with an electric fan on a BMW:

You can install an electric cooling system according to a simplified scenario. To do this, you will need the following components:

- motorized cooling fan that can be adapted to your radiator;

- a set of wires with a cross section of at least 6 sq. mm.;

- 40 Amp fuse;

- automotive relay for a current of at least 30 Amperes;

- thermal relay, it is possible Zhiguli for a response temperature of 87 degrees Celsius.

The thermostat can be installed on a radiator or on a metal surface near the thermostat by gluing. Next, you need to collect wiring diagram turn on the fan similar to the VAZ. Such the simplest circuit can last five seasons without failure.

Constantly check the moment of operation of the viscous coupling, especially in the warm season, control the temperature of the engine in traffic jams. If it approaches critical values, seriously consider replacing the viscous coupling with an electrical system. By the way, these two systems can work in parallel for greater reliability.

Video - replacing the viscous coupling of the cooling fan with Toyota Mark 2:

How to protect yourself from the blinding sun and headlights while driving?

If the cooling fan impeller is rigidly connected to any motor shaft, cooling would either be insufficiently effective at low speeds (overheating), especially in cold weather, or excessively effective at high speeds (underheating). Therefore, to adjust the intensity of the air flow passing through the radiator, a control clutch is installed between the shaft (pulley) and the fan impeller. The task of the clutch is to ensure slippage of the impeller relative to the shaft and thereby reduce the cooling efficiency when it is not needed.

At low temperatures, the fan speed is minimal, which allows the engine to warm up faster and at the same time reduces noise from the impeller. As the temperature rises, the fan speed will also increase.

On Ikarus buses, a pneumatically driven friction clutch of a fan (a kind of clutch) was installed. The regulation of switching on and off is carried out here by compressed air, depending on the temperature of the coolant. On cars, on some trucks, a viscous or electromagnetic clutch is installed in the fan drive.

With all the technical innovations in fan drives, internal combustion engines are still extremely inefficient in terms of cooling (up to 30% of fuel energy is spent on cooling, with a total efficiency of about 34% for gasoline internal combustion engines and about 50% for diesel ones).

[hide]

Viscous fan clutch

To uncover...

The viscous fan coupling is non-separable, and therefore does not require maintenance during operation. It provides a smooth change in fan speed.

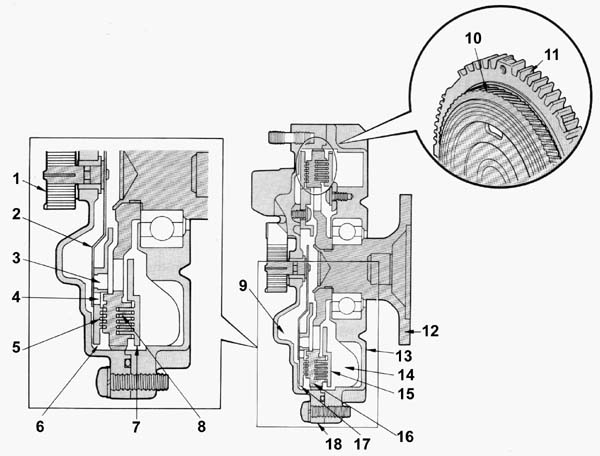

The clutch rotor is rigidly mounted on the shaft (in the case of Toyota, on the coolant pump pulley). Along the circumference of the rotor disk, oblique teeth are cut, which act as a pump for pumping oil. The clutch housing assembly (bearing housing and front cover) rotates around the rotor on the bearing.

Plates are installed on both sides of the rotor, separating the working chambers from the tanks. The front one (with inlet channels A and B and return channel) is fixed on the rotor cover, the rear one (with return channel) is fixed on the bearing housing.

1 - bimetal spring, 2 - bimetal, 3 - inlet B, 4 - inlet A, 5 - front chamber, 6 - return channel, 7 - return channel, 8 - rear chamber, 9 - front reservoir, 10 - teeth rotor, 11 - bearing housing, 12 - rotor shaft, 13 - bearing housing, 14 - rear reservoir, 15 - rear dividing plate, 16 - rotor, 17 - front dividing plate, 18 - front cover.

The working chambers are "mazes" formed by ribs on the rotor and on the dividing plates. Torque is transferred from the rotor to the housing by "internal friction" in the silicone oil. A bimetal spring mounted on the outer side of the clutch housing moves the plate, opening and closing the intake ports and adjusting the oil flow depending on the air temperature.

Operation of the viscous fan coupling

To uncover...

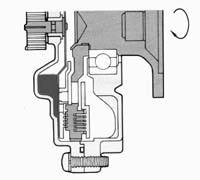

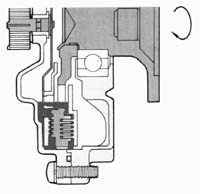

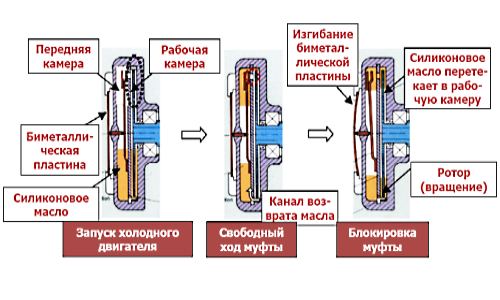

1. Cold air. When the rotor rotates, its teeth “pump out” oil from both chambers and the rear reservoir into the front reservoir through the return channels. As a result, its quantity in the chambers drops, the force transmission through the liquid decreases, and the fan speed becomes significantly lower than the speed of the main rotor.

1. Cold air. When the rotor rotates, its teeth “pump out” oil from both chambers and the rear reservoir into the front reservoir through the return channels. As a result, its quantity in the chambers drops, the force transmission through the liquid decreases, and the fan speed becomes significantly lower than the speed of the main rotor.

2. Warm air. Under the action of centrifugal force, the oil from the front reservoir is forced into the front chamber through the opened inlet A. The "viscous friction" between the rotor and the front plate increases, and the speed difference decreases.

2. Warm air. Under the action of centrifugal force, the oil from the front reservoir is forced into the front chamber through the opened inlet A. The "viscous friction" between the rotor and the front plate increases, and the speed difference decreases.

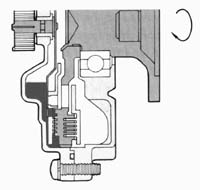

3. Hot air. Both inlet channels open, after which oil enters both working chambers. The volume of fluid in them and the "friction" are maximum, so that the transmission of rotation through the clutch is also maximum.

3. Hot air. Both inlet channels open, after which oil enters both working chambers. The volume of fluid in them and the "friction" are maximum, so that the transmission of rotation through the clutch is also maximum.

Since the speed is controlled by changing the volume of silicone oil in the clutch cavities, its leakage inevitably leads to a decrease in the fan speed and possible overheating of the engine.

Some of the early design couplings did not have a rear reservoir. Since, after the engine stops, the oil flows into the lower part of the clutch, here its level in the chambers increased significantly and immediately after the engine was started, when the “friction” between the rotor and the plates was high enough, the fan speed increased too much. With a rear reservoir, the liquid level in the chambers is lower when the engine is turned off, and after starting it drops faster - as a result, the noise level from the fan is reduced.

Some of the early design couplings did not have a rear reservoir. Since, after the engine stops, the oil flows into the lower part of the clutch, here its level in the chambers increased significantly and immediately after the engine was started, when the “friction” between the rotor and the plates was high enough, the fan speed increased too much. With a rear reservoir, the liquid level in the chambers is lower when the engine is turned off, and after starting it drops faster - as a result, the noise level from the fan is reduced.

[hide]

[hide]

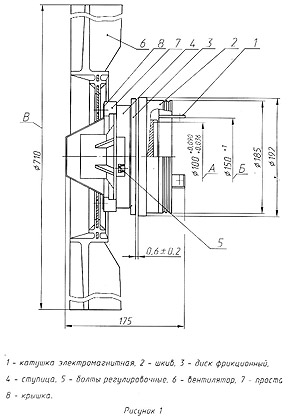

Electromagnetic fan clutch

To uncover...

The electromagnetic clutch is the simplest in design and has the ability to completely turn off the fan (open the shaft). The disadvantage of the electromagnetic clutch is the impossibility of smooth switching on (the presence of only two states, on/off).

The clutch consists of an electromagnet which is mounted on the fan hub. The hub is connected by a leaf spring to the armature, which rotates freely with it on a bearing. The thermal relay is activated when the temperature of the coolant in the upper tank of the radiator reaches 85-90 ° C. The relay contacts close, an electric current enters the coil, under the influence of which it attracts an armature, and the hub together with the fan starts to rotate. If the temperature of the coolant drops to 80-85 ° C, then the thermal relay contacts open and the fan turns off.

Viscous coupling is a device that, although not very widely, is used in cars. For example, they work on SUVs with automatically connected all-wheel drive, and are used in some cooling systems. Therefore, it is useful for every motorist to have an idea about their device, principle of operation and verification in case of malfunctions.

What is a viscous coupling?

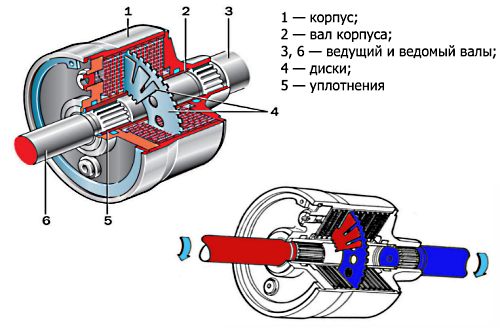

The part (derived from the Latin word viscosus - viscous) or viscous coupling (VZ) got its name thanks to the main principle used in its work. It consists in the transfer of the momentum of motion between two elements of the system not due to the mechanical connection between them, but due to viscous friction.

This principle allows you to put the depth of communication and the share of energy transmitted from the leading element to the slave, depending on the mismatch in motion. As the energy transfer medium, a liquid is used, the viscosity of which varies depending on the intensity of mixing and/or heating.

The operation of a viscous coupling is illustrated by a simple example. Two discs are placed in a common sealed housing, one of which is connected to the drive shaft, and the other to the driven one. The distance between them is quite small, but there is no constant connection. The space between the disks is filled with a dilatant fluid (the viscosity of which grows the stronger, the more intense the shear deformation in it, i.e. mixing),

As long as the shafts move in concert (at the same speed), the viscosity of the liquid filling the body is low, the movement of the disks does not experience resistance and remains independent. When the speed of one of the shafts changes, the angular velocities of the disks change relative to each other, the liquid layers between them shift, and mixing begins. At the same time, the viscosity of the substance increases, the friction force of the disks against it increases. Accordingly, the force from the drive shaft and the disk fixed on it (accelerating or braking) is transferred to the disk of the driven shaft, due to which the rotation speeds are equalized.

The viscosity of a substance increases the more, the greater the difference in speeds. With a particularly strong mismatch, a hollow blocking of the shafts occurs due to the fact that the properties of the dilatant liquid become similar to those of a solid body.

Video (basic principle of operation).

Types of viscous coupling.

Currently, 2 types of devices are used in cars:

- with a constant volume of dilatant fluid;

- in which the working volume of a substance depends on external conditions.

The first are used in the so-called. self-locking differentials in vehicle transmissions, including for automatic connection all-wheel drive.

The scope of the latter is engine cooling systems, here they are used to control the fan.

The device and principle of operation of viscous couplings for transmissions.

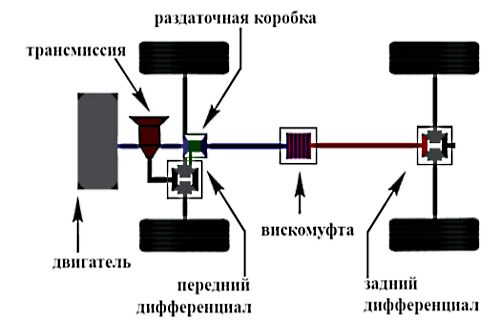

One of the main purposes of the part used today in the automotive industry is the automatic connection of all-wheel drive.

The design of such a unit includes two groups of round plates - disks with protrusions and holes. One group of plates is connected to the drive shaft, the other - to the driven. Leading and driven disks alternate with each other, there is no mechanical connection between them. The whole structure is placed in a sealed case and filled with a silicone-based liquid.

For use as a self-locking center differential, the viscous coupling is located between the transfer case and one of the vehicle axles. The second axle is permanently connected to the engine.

The work of the part in the transmission.

When driving in normal mode on a normal surface, the angular speeds of the wheels of both axles are the same. The viscous clutch disks rotate at equal speeds, the transfer of torque from the engine to the driven axle is minimal. In fact, the car becomes completely front- or rear-wheel drive.

When driving on ice, snow, mud, irregularities, the synchronization of wheel rotation is disturbed, the viscosity of the fluid in the device increases, increasing the transmission of torque to the second axle. Theoretically, such power transfer in some emergency modes can be up to 100%, although, as a rule, even a partial connection of the second axle is enough to safely overcome the problem area.

Important! It should be understood that the viscous coupling is by no means a full-fledged center differential that ensures the redistribution of engine torque to both drive axles.

The use of the part is justified on uneven surfaces, in icy conditions in the city or on a wet road. When driving in complete off-road conditions, the delay in the operation of such a self-locking differential is unacceptable. In addition, constant loads can lead to overheating of the liquid in the device, loss of its working properties and complete self-locking, which is fraught with breakdowns of other vehicle systems.

At present, on vehicles with automatically connected all-wheel drive, viscous couplings are operated in "pre-launch mode". It is characterized by a constant transfer of 5% to 15% of the engine power to the driven axle, which significantly reduces the reaction time of the mechanism.

Video (device operation on Hyundai Tucson JM and Kia Sportage FQ cars).

The use of viscous couplings for wheels of one axle.

Another option for using the clutch is also possible - for wheels of one axle. In this application, the device is installed between the axle differential and the axle shaft. In this case, when cornering or slipping of one of the wheels, the device helps to redistribute the moment between them, ensuring the safe execution of a maneuver or the passage of a problem area.

There are solutions in which a pair of parts is placed on the wheels of one axle. This design allows you to abandon the axial (cross-axle) differential. At the same time, the use of a pair of viscous couplings makes it possible to provide all modes - both differential rotation and blocking of the axle wheels.

Pros and cons of all-wheel drive viscous coupling.

Like any device, air intakes in all-wheel drive vehicles have both advantages and disadvantages.

Advantages:

- Automatic connection of all-wheel drive or mutual blocking of the axle wheels, which significantly increases the cross-country ability and traffic safety on difficult surfaces;

- The simplicity of the technical solution and, accordingly, its low cost and reliability - manufacturers most often make devices maintenance-free, counting on a service life equal to the life of a car.

In practice, a mileage of 90-100 thousand km (in difficult conditions and less) becomes the limit due to the loss of fluid properties and malfunctions in other vehicle systems. With such a run, it is recommended to replace the device.

Flaws:

- The delay and non-linearity of operation do not allow for absolute control over the all-wheel drive;

- In most cases, on vehicles equipped with viscous couplings, manual switching on / off of the second drive axle is not provided;

- Limited dimensions impose restrictions on the transmission of torque, as well as on the possibility of long-term operation in a loaded state (overheating and failure are possible);

- The joint work of the air intake and electronic systems such as ABS, ESP and similar is difficult, since they solve opposite problems.

Viscous coupling in cooling systems.

In cooling systems, VZ is also used to control the fan. It solves one of the important tasks - connecting the unit only when the engine is warming up.

Its design includes:

- Housing rigidly connected to the fan;

- A disk with an impeller (finned) connected to the water pump shaft;

- reserve capacity;

- Valves for overflowing the substance and a bimetallic plate or other temperature-dependent assembly for controlling the valves.

How does a viscous fan clutch (CO) work?

Until the engine is warm, the thermostat directs the flow of coolant in a small circle. In this mode, the substance in the viscous coupling is squeezed out by a rotating disk into a reserve tank. There is no engagement between the disk and the case, the fan does not rotate.

The flow of coolant into the radiator causes deformation of the bimetallic plate, actuation of valves and accumulation of fluid in the viscous coupling not in the reserve tank, but in the space between the disk and the housing. Due to viscosity, the unit is blocked, to which power is transmitted from the shaft. The fan starts to rotate, directing the air flow to the radiator, reducing the temperature of the coolant.

When it cools down to the threshold level of the temperature-dependent unit, the paths for liquid overflow open, the force of viscous friction between the disk and the case decreases, the fan stops.

Viscous check.

Any suspicion of abnormal operation of a part requires immediate investigation, as its failure can lead to serious damage to major systems.

How to check in transmission?

The most accurate results are obtained by checking the viscous coupling removed from the transfer case.

For this it is enough:

- Remove item;

- Turn the differential gear with a dynamometer wrench (or measure the force with a spring dynamometer).

The force should not exceed the limits set by the manufacturer (can be found in the technical specifications for the device and manuals for components).

You can check the part without removing it. For this you should:

- hang out the wheel of the driven axle;

- try to turn it by measuring the force with a dynamometer;

- Calculate the moment from the known wheel diameter

If the value obtained does not exceed the limits specified by the manufacturer, the part is working. If the wheel could not be turned at all, the device must be urgently changed.

Video tutorial.

How to check the viscous coupling VO?

Checking the viscous coupling VO is not difficult:

- Start the engine "cold";

- After 30-60 seconds, the fan noise will decrease - it will switch to idle mode (at this moment it can be stopped by any obstacle, for example, a folded newspaper, but safety precautions do not recommend doing this);

- After some time, when the engine warms up (controlled by a temperature sensor), the viscous coupling will begin to increase the speed of the unit;

- In this case, there should be an unambiguous reaction to an increase in engine speed - the engine rotates faster - the fan rotates faster.

You can also check the device in motion (more precisely, in the parking lot in the middle of the day). When the temperature rises to idling- we can definitely talk about problems with a viscous coupling.

Video (one way to check).