Radiator cooling fan: Principle of operation and repair. Radiator cooling fan: device and possible malfunctions

Engine cooling fan - a device that allows you to forcibly organize the airflow of a heated engine and a radiator of the cooling system while the car is parked with the engine running.

The role of the fan in the cooling system

The process of evolution of the cooling system initially went in two main ways, therefore, they found application in production cars: air cooling and liquid (or rather, hybrid). The fan is used in both types of cooling systems, since the final carrier that dissipates the heat removed from the engine is air. The fan performs the function of a device that provides a constant and uniform heat removal to the atmosphere.Types of engine cooling fans

There were only two efficient fan designs in the process of development of the cooling system. The first type is a mechanical fan with a belt drive from a pulley mounted on. To ensure the safety of the blades during high speed rotation of the crankshaft, the fan impeller is connected to the pulley through a hydromechanical drive, which, depending on the design, is called a thermal coupling or fluid coupling.Most often, an automobile engine is supplied with an eight-bladed impeller, although the number and shape of the blades are not regulated anywhere.

This device is a type filled with silicone gel that changes properties under the influence of temperature. The degree of clutch blockage affects the fan speed. When the engine is untwisted, the clutch begins to "slow down" the rotation of the impeller, which would inevitably break at a rotation speed of 3000 rpm and above. The thermal coupling and the hydraulic coupling differ from each other in design and principle of operation, but both of them allow you to keep the speed of rotation of the impeller within narrow limits, allowing it to accelerate and slow down only as much as is necessary for efficient heat removal, and no more. With the development of modern electronic components and the beginning of their use to control processes in the engine, appeared and quickly gained popularity. The drive consists of an electric motor and a control system that controls the intensity of the cooling fan, depending on the readings of the temperature sensor. The use of electronics made it possible to bring the uniformity of engine cooling to a new qualitative level in comparison with an inert "analogue" system based on a viscous coupling.

The device and principle of operation of the engine cooling fan

Viscous fan Fans with viscous coupling currently meet at cars rarely. Their use is limited to models with a longitudinal engine, and even then, the convenience of electronic control gradually reduces their use to nothing. The only segment in which the installation of a belt-driven fan is preferable is serious SUVs, such as UAZ or designed to force water barriers. The electronics are afraid of water, and the viscous coupling is sealed, and will not fail after "bathing". The sleeve is filled with silicone oil, the volume of which is approximately 30-50 ml. Fan with electronic control unit The electric fan mechanism includes: an electronic motor control unit, a temperature sensor, an electric motor and a fan switch relay. On modern cars Increasingly, two sensors are being installed that record the temperature of the coolant. One of them is built into the pipe at the outlet of the radiator, the other - into the pipe at the outlet of the engine or in the thermostat housing. In this case, the fan is controlled based on the difference in the readings of these sensors.

Viscous fan Fans with viscous coupling currently meet at cars rarely. Their use is limited to models with a longitudinal engine, and even then, the convenience of electronic control gradually reduces their use to nothing. The only segment in which the installation of a belt-driven fan is preferable is serious SUVs, such as UAZ or designed to force water barriers. The electronics are afraid of water, and the viscous coupling is sealed, and will not fail after "bathing". The sleeve is filled with silicone oil, the volume of which is approximately 30-50 ml. Fan with electronic control unit The electric fan mechanism includes: an electronic motor control unit, a temperature sensor, an electric motor and a fan switch relay. On modern cars Increasingly, two sensors are being installed that record the temperature of the coolant. One of them is built into the pipe at the outlet of the radiator, the other - into the pipe at the outlet of the engine or in the thermostat housing. In this case, the fan is controlled based on the difference in the readings of these sensors. Almost any car engine, even very old ones, can be equipped with an electrically driven fan with a thermal switch.

When controlling the fan, other input devices are also used: and the crankshaft speed sensor. Their readings are necessary to determine the mode of operation of the electric motor. The signals from all sensors are transmitted to the electronic control unit, which, after processing them, activates the relay for turning on the engine cooling fan and regulates the speed of rotation of the impeller. Fan with thermal switchIn older systems, there was no electronic control unit, and the function of turning on / off the electric motor was performed by the so-called "thermal switch", which is often mistaken for a temperature sensor. In fact, a "real" temperature sensor is almost always installed in a housing. It is from him that a signal is sent to the scale in the cabin, since the temperature in the immediate vicinity of the combustion chamber is more important for measurement. The thermal switch also responds to an increase in the temperature of the coolant (but in the radiator). It is graduated to a certain temperature (for example, 85 and 70 degrees Celsius) - to turn on and off. If the temperature exceeds a predetermined threshold, the contacts inside the thermal switch close, closing the fan power circuit. The electric motor, to which current is applied, begins to rotate the impeller. As soon as the temperature has dropped to the lower threshold, the contacts open and the fan stops.

Engine Cooling Fan Operation Issues

A faulty engine cooling fan will inevitably cause the engine coolant temperature to rise. If you notice, you can stop and check the operation of the fan yourself.Electric fans are installed both on the outside of the radiator and on the side of the engine compartment. There is no consensus among engineers about the advantages of a particular installation.

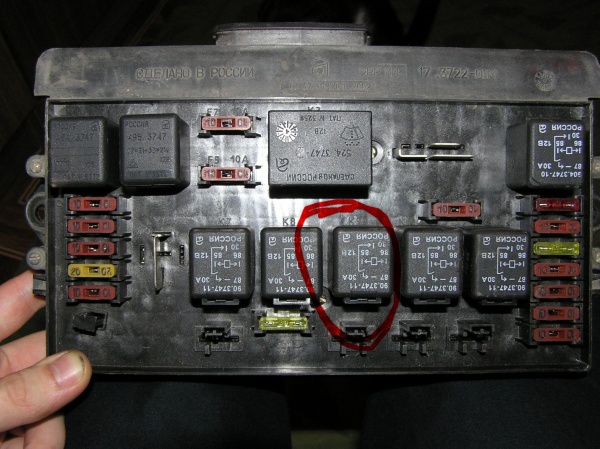

To diagnose an "analog" fan, just lift the hood and look at the impeller blades. The viscous fan is always moving, so if you observe rotation, the cause of overheating is most likely a breakdown in another component of the cooling system, such as a thermostat. A sign of viscous coupling failure may be too low fan speed at high speeds. If your machine has an electric cooling fan, and you see that it does not work when it is clearly overheated, use the following method: disconnect the connector from the thermal switch screwed in, as a rule , to the bottom of the side tank. Taking the connector in your hands, short the 2 sockets of the plug with a small piece of wire. In this case, the fan should be forced to work.This method cannot be recommended for owners of the most modern cars with an electronic fan speed control device. The maximum that the owner can do is to check the integrity of the corresponding . Further diagnostics should be entrusted to professionals.

The engine plays a vital role in the operation of any vehicle. It depends on the characteristics and condition of the power unit how fast the car will move and what capabilities it will have. The cooling system allows timely regulation operating temperature motor and protect it from overheating. Today we will consider such a device as an engine cooling fan, and find out why it is needed and what types of such devices are divided into official classification.

Functions and purpose

The cooling fan is designed for direct intake of hot air from the radiator. In some older cars, the fan was the only device that kept going in the heat and during intense work. Unfortunately, even the most powerful fan is not enough to provide full cooling, therefore, in all modern models, a crankcase exhaust system equipped with a special valve is provided.

In addition, in addition to the crankcase ventilation valve, various blocks and controllers are introduced into the cooling devices, which allow you to accurately determine all the necessary engine parameters in order to cool it most efficiently.

It is worth noting that along with the crankcase valve and fan, the cooling circuit also includes a radiator filled with liquid and a water pump that circulates it in the engine. This allows you to achieve the greatest efficiency and, as a result, a longer resource of the engine itself.

mechanical type

Let us now consider the schemes and principles of operation that an engine cooling fan has, the main types of drives and their power sources.

In the last century, the most popular systems were those that operate rather primitively and do not have numerous sensors and controllers that facilitate the functioning of both the fan itself and other car devices.

One of the simplest such devices is a cooling fan that operates on a mechanical principle. This model does not have any sensors or controllers, and the intensity and speed of rotation of the impeller depends only on the speed of the engine flywheel.

The mechanical type is driven by a flywheel through a belt drive. This allows not to use additional devices in the form of sensors and not to complicate the operation scheme with various expensive elements.

Viscous fans

Fans take on a relatively small role in cooling devices compared to liquid systems. However, in exceptional cases, high blowing power and a sufficiently robust impeller are required, which is not afraid of adverse conditions in the form of moisture and dust.

One of these devices is a hydraulic fan. Hydraulic fans are widely used, mainly on cross-country vehicles, which, for one reason or another, are often forced to overcome water fords. Here, the maximum tightness of the entire cooling device is extremely necessary, due to which the impeller and the crankcase ventilation valve will be protected from water to the maximum.

The principle of operation of such a device is quite complicated. However, those who in one way or another came across the study of the principles of functioning of modern automatic transmissions will easily master hydraulic fans.

In hydraulic fan systems, everything is based on the functioning of two clutch packs, which are located in a sealed chamber filled with silicone. The controller collects data on the rotation speed and temperature of the engine, and on the basis of them issues an indication to issue a certain pressure to the hydraulic fan. Thus, a strictly defined torque is transmitted to the clutches, and the fan speed can vary.

Fans with controls

Fans equipped with a control unit and their own controller are used in the vast majority of manufactured this moment models. The advantages of devices with control units are that the controller can collect information about all the necessary characteristics of the motor and, based on them, issue commands for programmed motor cooling modes.

Along with the crankcase ventilation valve control unit, there is also a system of sensors for crankshaft speed, fan blade speed and other vital signs.

The task of the controller is to receive all the necessary information from the sensors and give an impulse to change the rotation mode. This helps to save the resource that the fan motor has and more efficient cooling of the power unit.

Fan with temperature sensor

Fans with a thermostatic sensor have found application in car models of the second half of the last century. They also interact with the crankcase bleed valve and have some, albeit primitive, automatic electronics.

What is good about this type of fan? First of all, this is the maximum simplicity of the equipment used and its simple repair, which even an inexperienced master can do. The second advantage is extremely inexpensive spare parts and components, which contribute to the considerable popularity of the use of such systems on domestically produced cars.

The way in which such a device functions is quite simple and primitive. The fan is connected directly to the temperature sensor, which acts as a relay and switch at the same time. When the coolant is heated to a certain threshold, the sensor is triggered and the fan is set into rotation. Similarly, it turns off as soon as the temperature of the antifreeze returns to normal.

Engine degassing

Cooling fans, of course, play an extremely important role in maintaining the operating temperature of the power unit in all modes of operation. However, on modern cars, a crankcase exhaust valve is also used, which allows additional cooling of the engine and prevents the formation of soot on the engine walls.

The task of the crankcase exhaust valve is to open at strictly necessary moments and release oil, fuel and water vapors that accumulate in the engine into the manifold.

Such electronics functions as follows. A sensor is installed in the engine crankcase that analyzes the current gas pressure in the system and constantly transmits information to the computer. The latter, in turn, checks the information issued by the sensor and releases gases if their pressure has reached a certain value. Thus, there is an additional cooling of the engine and preventing its clogging.

Summary

Engine cooling fans are extremely important devices, without which maintaining a constant temperature of the motor and protecting it from overheating would become impossible. Therefore, it is highly recommended that you check this unit regularly to avoid problems in transit and breakdowns that require costly and difficult repairs.

The operation of any internal combustion engine that modern cars are equipped with is inevitably associated with the release of a huge amount of thermal energy. If it were not for the automotive cooling system, which effectively absorbs heat and releases it to the surrounding air, the use of the car would be impossible. In the cooling system of any vehicle, the leading role should be played by the radiator and the cooling fan - it is thanks to these two components that excess heat is quickly removed from the engine.

Types of cooling fans

The fan plays a very important role - it guarantees constant air circulation in forced mode and motor cooling. Constant and high-quality heat dissipation allows the motor to long time work normally, without overloads, and normally its temperature rarely exceeds 95 degrees. For all the time of the automotive industry, the radiator fan has been produced with three types of drives.

Diagram of the electrically driven cooling system

The basic circuit for controlling the electric radiator cooling fan consists of the following elements:

- antifreeze temperature sensor;

- electronic control unit;

- relay;

- air flow meter.

The electric radiator cooling fan does not run constantly, but only turns on when the control unit transmits a corresponding signal. Previously, it receives and analyzes signals from installed sensors. In the event that the vehicle is equipped with a towing device or a climate system, two fans can be installed at once. Accordingly, there will also be two switching relays, and they can work both in pairs and each individually.

It is the electric radiator cooling fan that allows automakers to implement the controlled coast function. This improves the performance of a modern engine, including a forced cooling system for it after it is turned off. The intelligent control system of such a system includes cooling for a certain time when the engine is not running, which ensures its rapid and efficient cooling.

If the radiator cooling fan does not work

Despite the relatively simple design, which does not contain complex elements, it is often not so easy to deal with a breakdown on your own. When the radiator cooling fan fails, the normal operation of the engine is compromised and the problem must be corrected as soon as possible. If the engine temperature is constantly "rolling over", the first thing to do is to check the performance of the device itself.

You can do it yourself, no special skills or knowledge in electrics are required. It is necessary to close the terminals in the plug manually using a piece of wire. It is worth noting that if a dual temperature sensor is installed on the car, to check the device, you will first need to close the wire with white and red insulation, and only then with red. If the radiator cooling fan is in good condition, it should start in forced mode.

For a final check of performance, you can connect the red and black wires - a working fan should start working at maximum speed. If these measures did not lead to the start of the cooling fan, the causes of the malfunction may be as follows:

- the temperature sensor has failed;

- fuses are blown;

- the fan itself is faulty.

If the replacement of the fuses did not help, the rest of the repair activities should be entrusted to specialists, since the cooling system becomes more difficult from year to year, and independent interventions without appropriate education can have sad consequences for the entire cooling system. The self-check algorithm is shown in the video:.

If the fan does not turn off

An equally common problem is the situation in which the radiator fan often works or it does not turn off at all. Normally, this should not be, so you should perform self-check. With the ignition on, the wire tip is removed from the sensor. Fan operation should stop. If it continues to work, this indicates a malfunction of the sensor, which must be replaced.

In this case, many continue to check, switching to the electric motor of the device - it is not advisable to do this. What you should pay attention to is the condition of the terminals. Often, interruptions in the operation of the cooling fan are precisely in oxidized, contaminated terminals, the normal passage of electric current through which is difficult.

Other Common Faults

The most common problem for a motorist is excessive noise when the radiator cooling fan is running, as well as high level vibrations. If the sound of the fan tends to override the noise of the engine, the following may be the cause of this phenomenon:

- a loose bolt that secures the impeller to the pulley;

- part of the blade is broken off;

- there is no lubrication on the electric motor or it is not enough;

- worn bearing.

All of the above must be eliminated, since improper operation of the radiator fan reduces the efficiency of the entire engine cooling system. These reasons can lead not only to overheating of the motor, but also to collateral damage. So, a poorly tightened blade can fall off the pulley at high rotation speed, which will damage the radiator itself, which will have to be soldered or replaced with a new one.

Is self-repair possible?

Repair of a fan for a car radiator is not only possible, but also necessary, since the performance of the engine itself depends on this unit. In most cases, it is simply impractical to change it completely when problems arise, self-repair is enough. To do this, the fan will need to be removed. Before doing this, be sure to disconnect the negative terminal with battery and disconnect all wires leading to the device. After the mounting bolts are unscrewed, the cooling fan can be removed and proceed to its inspection.

Very often, the cause of the malfunction is just the accumulation of a large amount of dirt, which is cleaned with a stiff brush. The procedure should begin with the blades of the device. If possible, you can blow out all the components of the cooling fan with compressed air. After that, it will not hurt to check the integrity of the electric motor winding. This is especially necessary if intermittent operation of the device has been recorded before. Each coil is inspected carefully, paying attention to integrity.

Of course, there are problems that cannot be fixed on your own. So, the installed sensors, if they are out of order, cannot be repaired. It also makes no sense to repair a burned-out electric motor - in this case, it must be completely replaced with a new one. At the same time, this must be done immediately, since the operation of a car with a faulty cooling system is impossible.

The cooling system is a mechanism that is designed to cool motor components that are heated during operation. In modern cars, it also performs additional functions for cooling the following components:

- oils in the lubrication system;

- working fluid in automatic transmission;

- exhaust gases in an appropriate recirculation system;

- air in the turbocharging system.

In addition, air is heated in air conditioning, ventilation and heating systems.

Types of cooling systems

According to the method of cooling, the systems under consideration can be divided into several types. This:

- air (open type);

- liquid ( closed type);

- combined.

In the first case, air flow is used to perform the functions. The liquid cooling system removes temperature from the parts through the flow of liquid. The combined type provides for the combination of the listed ways to reduce it.

Most often, a closed system is installed on vehicles. This is due to the fact that it is able to provide efficient and uniform cooling of parts of the power unit. In addition, this design produces a minimum level of noise during operation. Therefore, considering this topic, it is worth paying more attention to the liquid cooling system.

Cooling system design

It is worth noting that different cooling systems are installed for gasoline and diesel engines, however, their designs have a similar design. They include a lot of components. The main ones are the coolant radiator, radiator cooling fan, oil cooler, thermostat, centrifugal pump, heat exchanger and expansion tank.

The design of the cooling system also includes a "cooling jacket" of the motor. To perform the regulation of mechanisms, special controls are used. With their help, you can ensure the optimal level of cooling of the power unit during operation.

Cooling fan and its varieties

A cooling fan is a device that performs the function of increasing the cooling intensity of the radiator and motor. This is possible due to the constant and uniform removal of the tempo from the details into the atmosphere.

To date, there are two workable designs of the device in question: mechanical and electrical. The cooling fan of the first type works by transmitting torque from the crankshaft pulley through a V-belt drive.

On modern cars, the use of an electrically driven fan is more relevant. Its design includes a control system and an electric motor. The readings of the temperature sensor directly affect the intensity of the operation of this device. This is the most optimal option, which has advantages over mechanical counterparts, which is why it has gained popularity.

Fans that cool the engine and radiator can be of three types: viscous, electronically controlled and thermally switched. These designs have significant differences, so each of them is worth considering in more detail.

Viscous fans

A system based on a viscous coupling is not common. It is equipped with machines with a longitudinal arrangement of the power unit, and it is also used on large SUVs used to overcome water obstacles. This is due to the principle of operation of such a cooling fan. The viscous coupling is a completely hermetic design, therefore it is reliably protected from water penetration. Under its influence, electrical systems will instantly fail.

The viscous coupling is filled with special silicone oil or gel. It changes its properties when exposed to temperature. The rotation speed of the device will be reduced or increased depending on the heating level. This cooling fan consists of a sealed housing filled with silicone fluid, as well as drive and drive shaft disk packs. The principle of operation is based on the transfer of rotation from the drive to the driven shaft due to disk packs.

Electric fans

The radiator and engine cooling fan with electric drive has a more complex design than the previous system. In addition, it is more modern, so it is found on many new cars. The device includes an electric motor, a temperature sensor, an electronic control unit, and a cooling fan relay. Most appliances have two temperature sensors. One is equipped with a pipe coming out of the radiator. The second sensor is built directly into the thermostat housing, and can also be located in the branch pipe coming out of the motor. The difference in sensor readings affects the operation of the cooling fan control unit.

Setting the operating mode of the electric motor of the device requires an air flow meter, as well as a sensor that monitors the speed of the crankshaft. The control unit will receive the corresponding signals from all sensors and process them. Then the cooling fan relay is activated, which will monitor the speed of rotation of the impeller after the system is turned on. Such devices are often installed by car manufacturers in our time.

Fans with thermal switch

Similar mechanisms were installed on cars before the invention of the electronic unit. For example, the VAZ cooling fan is also equipped with a thermal switch. This device is responsible for turning on / off the electric motor of the system.

The principle of operation of this type of cooling fans is as follows: a signal is sent from a temperature sensor, which is installed in the cylinder block housing, to a special scale located in the passenger compartment. This indicator and the response of the thermal switch to changes in the temperature of the liquid in the radiator affect the procedure for turning the engine on and off.

If the temperature of the cooler is increased to the maximum, the contacts connected to the system power circuit will be closed inside the thermal switch. Then current will be supplied to the electric motor, which will bring the fan impeller into rotation mode. The contacts will open if the temperature drops to the minimum limit, which ensures that the device turns off.

Diagnosis of malfunctions of the temperature sensor of the cooling fan

The cooling fan is not immune to damage, even if it has the highest quality. If such a problem occurs, urgent measures should be taken to eliminate it, since a system malfunction can lead to overheating of the motor. First of all, it is worth diagnosing and finding out why the cooling fan is not working.

To test a single temperature sensor, you will need to dismantle its connector and close the terminal in the plug with a regular wire. The device should turn on. For a dual sensor, short the red and red/white wires first, and then the red and black wires. Slow and accelerated rotation will be observed (respectively). If this does not happen, the cooling fan will need to be repaired or replaced.

Fuse Fault Diagnosis

What to do if the cooling fan does not work, it became clear. However, what should a motorist do if the system turns on, but nevertheless it is inoperative? In such cases, there is no problem with the temperature sensor. If there is a similar problem, it is advisable to check the cooling fan fuse, which may be damaged.

To check, you will need to supply power to the red-white wiring from the positive terminal of the battery, and from the negative - charge to the brown wiring. In this case, the device should turn on. If this does not happen, you need to check the condition of the plugs, connectors and cable, which are quite simple to replace.

Fan repair and replacement

Motorists often have experience in car repair, so they can independently diagnose mechanisms and take measures to troubleshoot. In the absence of relevant knowledge and skills, it is worth contacting specialists. Repair and replacement of the cooling fan will be qualitatively carried out in a specialized center. In addition, this will keep the warranty on the car, if it has not expired.

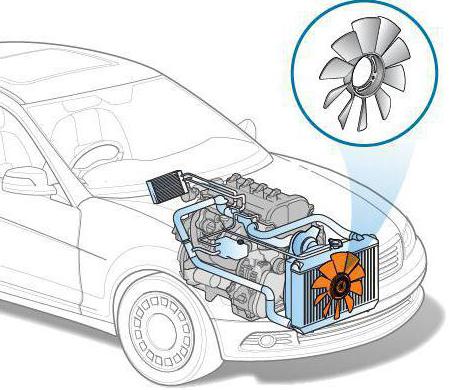

In a liquid engine cooling system, heat from the coolant is removed to the atmosphere using a special heat exchanger - a radiator. But very often situations arise when the radiator cannot effectively remove heat, in which case the radiator cooling fan comes to the rescue. Read about this important component of the cooling system, its design and operation in this article.

The purpose of the fan and its place in the engine cooling system

An internal combustion engine generates a large amount of heat during operation, which must be removed, otherwise power unit will fail. This problem is solved by a liquid engine cooling system - it uses water or non-freezing liquid (antifreeze) as a working fluid, which circulates in the cylinder block and in the cylinder head. The liquid takes heat from the engine, and, accordingly, heats up itself, and now it becomes necessary to take heat away from it - this problem is solved with the help of a radiator.

The radiator of the engine cooling system is located in such a way that during the movement of the car a stream of incoming air is directed at it - this significantly accelerates the transfer of heat from the radiator to the air, which means it cools the liquid faster. But the car is not always in motion, and in traffic jams or during long-term parking with the engine running, heat is removed from the radiator much worse. This is fraught with overheating of the engine with all the ensuing consequences. The same situation can occur when driving at low speeds, especially on a hot day or in the southern regions.

Overheating of the engine in such situations is prevented by a simple but very effective device - located in front of the radiator. This fan, turning on when the cooling system reaches a critical temperature during parking, creates the necessary air flow through the radiator, ensures normal heat removal from it into the atmosphere.

The fan plays a very important role in the car, but at the same time it has an extremely simple device and principle of operation.

Device and types of fan

1 - radiator;

2 - radiator cap;

3 - fan;

4 - fan motor;

5 - fan casing;

6 - sensor for turning on the fan motor;

7 - radiator drain plug;

8 - lower radiator support.

Structurally, the radiator cooling fan has an extremely simple device. This is usually a node that combines three elements:

An impeller with four or more blades (actually, a fan);

- Fan drive;

- Casing.