How to check the throttle position sensor. Device, principle of operation, diagnostics of the throttle position sensor Throttle Position Sensor (TPS)

Due to the unreliability of the throttle position sensor - TPS VAZ 2110 - the motorist has to determine the signs of a malfunction on his own. The general symptoms that appear when this meter breaks down can indicate a dozen more different problems. In order to accurately diagnose the failure of the sensor, it is worth figuring out how to check the TPS yourself and then successfully replace it without resorting to the help of a car service. The method will also be useful to owners of VAZ 2112-2115 and Lada Priora cars.

Location and principle of operation of the element

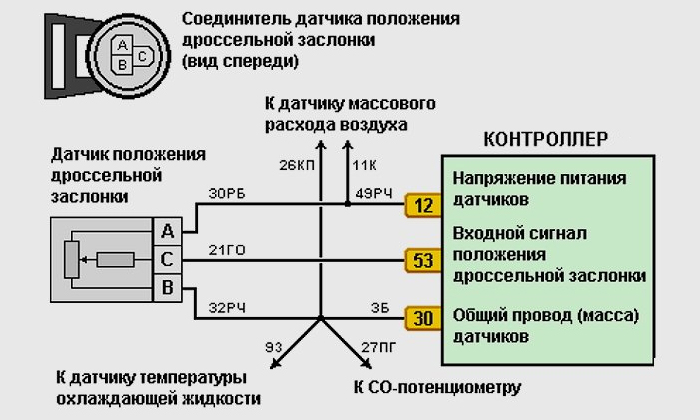

All cars of the "tenth" family with an injector, including the latest VAZ 2115 models, are equipped with many sensors. They are located at various points and are busy measuring various parameters, transmitting data in the form of electrical impulses to the processor that controls the operation of the engine. The location of the meters depends on their purpose, so the VAZ 2110 throttle position sensor is not difficult to find, it is in the same block with it. The same element is installed in the Lada Priora car.

The principle of operation of the device is very similar to the operation of a mechanical variable resistor, which have long been used in radio equipment to control the volume. Inside the case there is an element with a resistive coating, along which the slider moves. One contact is connected to this element, the second to the slider, and the third to ground. The device operation algorithm is as follows:

- A voltage of 5 V sent by the controller passes to the throttle valve sensor VAZ 2115. When the damper is fully closed, the resistance of the resistor is maximum, the controller receives only 0.3-0.7 V back.

- When the damper, which is mechanically connected to the slider of the part, is turned, the resistance decreases, and the output voltage increases.

- When the passage is completely open to air (the accelerator pedal is pressed to the limit), the resistance of the element is minimal, and a voltage of at least 4 V reaches the processor.

Based on the increase or decrease in the reverse voltage, the processor calculates the proportions of air and fuel in the mixture, as well as the duration of the signal applied to the injectors. True, when analyzing data, the controller gives preference to the readings of the air flow meter (DMRV), so malfunctions of the TPS do not lead to a complete stop of the car.

But at hard pressing on the accelerator pedal, the priority of the throttle sensor increases, because the controller needs to quickly supply a large amount of fuel to the cylinders. Given the sharp drop in resistance, indicating the full opening of the damper, it gives a signal to the injectors to inject an additional portion of fuel. The principle is similar to the action of a pump - an accelerator on carburetors, injecting fuel directly into the manifold using a membrane.

Accurate diagnosis of the state of the element

When the TPS starts to function incorrectly or fails completely, the fuel supply process is disrupted during a sharp acceleration of the car.

Therefore, the first sign of a sensor failure is jerks and dips when trying to dynamically accelerate.

Secondary symptoms look like this:

- when coasting downhill and the gear is engaged, the engine may stall and start again, causing jerks;

- the engine can stall both when you sharply press the gas pedal, and when it is released;

- fuel consumption increases.

The listed signs are of a general nature. Therefore, a more accurate check is needed to make sure that the TPS is malfunctioning or, conversely, to exclude it from the list of parts responsible for changing the behavior of the machine.

An accurate check of the state of the element is carried out with a special device - a multimeter equipped with contacts in the form of needles. First of all, you should make sure that the “Check Engine” display is not lit on the dashboard, which indicates a breakdown elsewhere, and the damper sensor has nothing to do with it. The further course of action is as follows:

- Switch the multimeter to the resistance measurement mode and, with the ignition off, find the negative wire.

- Turn on the ignition, move the switch to the voltage measurement mode and check it at the output of the sensor. The value must not exceed 0.7 V.

- Slowly open the damper manually. The voltage should also increase smoothly and, when fully opened, remain at a level of at least 4 V.

- Turn off the ignition and connect the contacts to the input and output wires, measure in ohmmeter mode. Slowly turn the damper and check that the resistance of the circuit decreases without jerking.

If the voltage indicators do not correspond or are absent at all, then the main reason lies in a faulty TPS. When the voltage and resistance of the resistor "jumps" when the damper axis is turned, this indicates wear of the resistive coating. Both defects definitely lead to the replacement of the part, it is impossible to repair it.

How to change a part?

Replacing the throttle position sensor in a VAZ car of the "tenth" family and Lada Priora is quick and easy. But there is one question - what type of sensor to choose? The fact is that new non-contact elements of increased reliability and equally high cost have appeared on the market.

They do not have a resistive film, and the principle of magnetic induction is used for operation. So, if possible, it’s better to put one on your “top ten” and forget about the troubles with the TPS for a long time.

The replacement operation is performed as follows:

- Disconnect the battery and disconnect the sensor from the connector.

- Unscrew the fastening bolts and remove the part. Don't lose the foam pad if you don't have a new one.

- Install a new element with a gasket and connect all the wires.

If the diagnostics and replacement are carried out correctly, then the engine should stabilize in all modes.

This sensor dreams of someone in nightmare and to some he just caused inconvenience.

The list of faults is extensive.

Typical symptoms dpdz sensor:

- Jerking of the car while driving;

- Bad start;

- Unstable turns on the twentieth;

- Loss of power;

- Increased consumption;

- The car stalls;

- Does not keep speed in the range of 1500 - 2000 thousand.

The other day he himself experienced how many problems he can deliver.

It all started with the fact that I began to wonder why my car could not keep the speed within 1500 - 2000 thousand and there was no smooth running, the car twitched while driving, but these inconveniences did not cause any particular problems.

Checking the DPS.

In order to check the voltage of the dpdz with a multimeter, you need to: disconnect the connector of the damper position sensor and connect the “+” of the multimeter to the power connector, black and white wire, and connect the “-” to the ground of the sensor, brown wire, turning on the ignition, the readings should be within 4.7 and 5 v.

Checking the throttle sensor signal, connect the “+” of the multimeter to the signal wire, blue or blue can be red, and “-” to the mass sensor terminal or any other mass of the car, the voltage should be between 0.3 and 0.6 v.

You can measure the resistance by connecting the “+” of the multimeter to the power connector and the “-” to ground, the readings should be from 4 to 9 kOhm.

In order to check the TPS tracks, you need to connect the connector to the sensor and connect the “+” of the multimeter to the signal wire of the sensor, and connect the “-” to the sensor ground and gently press the gas pedal, the readings should change smoothly and without jumps from 0.3 to 4.5 v, if you see a jump, a break in one place or another, then this means that the tracks in this position have been erased.

I checked the dpdz using the vag k + can commander diagnostic cord, the table clearly showed changes in the sensor voltage, the diagnostic cord allows you to determine the dpdz voltage much faster and more accurately, unlike a multimeter.

Repair and restoration of TPS.

graphite glue

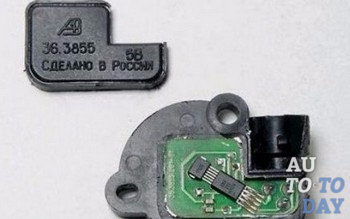

graphite glue I decided to remove and disassemble the sensor in order to check the integrity of the graphite tracks by eye. Having disassembled, I saw that the graphite tracks are really erased, I cannot determine the degree of wear. It was decided to purchase graphite glue to restore board tracks.

Restoration of graphite tracks of the sensor with graphite glue. I removed the sensor from the DZ and carefully cut it with a hacksaw for metal. other ways not to open it, carefully folded the board and applied a thin layer of glue to the tracks. Having done everything and gluing it, it remains to adjust the dpdz, which actually did not work out on my own even with an adapter for diagnostics, a multimeter and probes on hand.

The next day I went to the service station to set up dpdz. The slip was terrible and when shifting gears in different provisions RPMs fluctuated between 2500 and 4000 thousand.

The photo shows heavily worn tracks

The photo shows heavily worn tracks One hundred master reset everything to factory settings and adjusted the TPS. On the way home, I noticed a slip from 2nd to 3rd gear, the slip was not strong, for example, if switching occurs at 1800, it throws up to 2000, if at 1700 it throws up to 1800 or 1900 thousand, I noticed that if you really give gas, then this does not happen.

I called the service station and again told in detail about the problem, the master suggested that I check the wiring and the automatic transmission, and not sin on the sensor, since my thoughts were only about him, I went to disassemble this sensor again.

Bend the brushes into entire parts of the tracks.

This time I did not remove the throttle position sensor itself, so as not to go to set it up again, but removed the DZ completely along with the sensor, unfolded the sensor board with tracks and carefully cleaned it from the graphite glue that I applied before.

This time I planned to solve the problem by bending the brushes over entire parts of the dpdz tracks. Collected, started and went to check. The move is smooth, there is no slippage, and because of what I got into it - now it keeps the speed at 1400, 1650 at 1900 thousand, etc. in general, everything is as it should be, you can repair the sensor yourself and revive the sensor before buying a new one, the main thing is to do everything carefully and slowly.

Inside the dpdz there are graphite tracks along which brushes travel, the tracks can be restored with graphite glue, I found the most suitable chip and dip in the store for 150 rubles. But the most effective way is to bend these brushes to the sides for a whole part of the tracks, you need to do this very carefully, I used thin tweezers and a flat pizza. Do not think of degreasing the tracks or lubricating them with anything especially with cotton swabs and sponges. Graphite glue can also be used for other purposes, a very useful thing.

These brushes need to be gently bentDesign modern car includes many elements, it can be an expensive turbine, and a cheap throttle position sensor. At the same time, the cost of the part does not at all show its significance. So, the failure of the specified sensor can lead to a malfunction of the engine and expensive repairs.

Area of responsibility of the DPS

In this article, we will consider the features of this part and present detailed instructions its repair, adjustment and replacement. But before proceeding directly to the practical part, you should pay a little attention to the theory and consider what the throttle valve and its sensor are, what functions they perform and where they are located. So, the damper itself is a structural component of the engine intake system. Its function is to adjust the amount of incoming air, i.e. she is responsible for the quality of the fuel-air mixture.

Throttle position sensor sends information to the manifold about the status bypass valve. This is obvious from its name. The sensor can be film or non-contact (magnetic). Its design is similar air valve, and when it is in the open state, the pressure in the system is equal to atmospheric. But as soon as the element moves to the closed position, then the value of the above characteristic immediately decreases to a vacuum state.

Throttle position sensor sends information to the manifold about the status bypass valve. This is obvious from its name. The sensor can be film or non-contact (magnetic). Its design is similar air valve, and when it is in the open state, the pressure in the system is equal to atmospheric. But as soon as the element moves to the closed position, then the value of the above characteristic immediately decreases to a vacuum state.

The throttle sensor consists of constant and variable resistors, the resistance of which reaches 8 ohms. The voltage at its output, depending on the position of the damper itself, is constantly changing. The controller monitors the entire process, and the amount of fuel is regulated depending on the data received. If the TPS does not work correctly and produces distorted data, then insufficient fuel will enter the system or an excess of it will result, which will lead to engine malfunction and even sometimes its failure. In addition, the correct operation of the gearbox and the ignition timing depend on this device. We will not calculate how much the repair of these mechanisms will cost.

To diagnose any node or part, you should know its location. The throttle position sensor is located in the engine compartment. You can get to it after you find the throttle pipe, on which the TPS is fixed.

Why might we need to repair the sensor?

Nothing eternal has yet been invented, and this element also breaks down. Let's consider what reasons can provoke its failure and how it can be noticed. Throttle position sensor failures are mostly caused by normal wear and tear. So, the sprayed layer of the base, along which the slider moves, wears out. As a result, the device gives incorrect readings. Another reason for incorrect operation may be the failure of the moving core. And if one of the tips is damaged, then a number of scuff marks will appear on the substrate, which will lead to breakage of other elements. This will provoke a deterioration in contact between the resistive layer and the slider, and in some cases its absence.

Nothing eternal has yet been invented, and this element also breaks down. Let's consider what reasons can provoke its failure and how it can be noticed. Throttle position sensor failures are mostly caused by normal wear and tear. So, the sprayed layer of the base, along which the slider moves, wears out. As a result, the device gives incorrect readings. Another reason for incorrect operation may be the failure of the moving core. And if one of the tips is damaged, then a number of scuff marks will appear on the substrate, which will lead to breakage of other elements. This will provoke a deterioration in contact between the resistive layer and the slider, and in some cases its absence.

Understand that it's time to contact the service center or make self-diagnosis and, if necessary, repair, can be on the following grounds. First of all, listen to your car during idle move, if the revolutions "float", then do not hesitate to check the device. Another alarming sign should be the stop of the engine with a sharp reset of the pedal. And during acceleration, it may seem that the fuel does not enter the system, the car twitches and jerks appear.

Sometimes the speed seems to freeze in one range (1.5-3 thousand) and do not change its position even when switching to neutral gear. In addition, the dynamics are deteriorating. In general, the slightest violation in the operation of the engine should alert. By the way, pay attention to the dashboard, the “Check engine” signal light should light up on it. If this happens, then your car will automatically go into emergency mode, and after doing computer diagnostics, you will see that the reason lies precisely in the sensor. Checking the sensor without the help of an auto electrician

Sometimes the speed seems to freeze in one range (1.5-3 thousand) and do not change its position even when switching to neutral gear. In addition, the dynamics are deteriorating. In general, the slightest violation in the operation of the engine should alert. By the way, pay attention to the dashboard, the “Check engine” signal light should light up on it. If this happens, then your car will automatically go into emergency mode, and after doing computer diagnostics, you will see that the reason lies precisely in the sensor. Checking the sensor without the help of an auto electrician

It is quite easy to check the throttle position sensor, and everyone can cope with such a task, especially since you only need a multimeter for this, and when one is not available, a simple voltmeter will do. Then follow all the steps below.

We turn the key in the ignition and measure the voltage between the slider contact and minus. Its value should not exceed 0.7 V. Then we open the shutter by turning the plastic sector, again we take measurements. Now the device should show more than 4 V. We turn on the ignition completely, after which the connector is pulled out and the resistance is checked between any terminal and the slider. Now we slowly rotate the sector and observe the indicators of the measuring device. Its arrow should also smoothly change its position, and any jumps are a sign of a sensor malfunction. There is a little trick. If you do not want to disconnect the wires, then you can simply pierce them with a thin needle, although it is better not to be lazy and do everything as expected.

Adjustment in your garage

![]() Even a novice car enthusiast can adjust the throttle position sensors, most importantly, strictly follow the instructions below. Moreover, this operation does not depend on what principle of operation of the TPS is contactless or not. So, first we do the preparatory work. We disconnect the corrugated tube through which air passes, and thoroughly rinse it with alcohol, gasoline or another potent solvent. But one liquid is not always enough to achieve the best effect; you should also wipe the tube with a soft cloth. We carry out the same operation with the damper itself and with the intake manifold. In addition, do not forget to make a visual check, especially for the damper.

Even a novice car enthusiast can adjust the throttle position sensors, most importantly, strictly follow the instructions below. Moreover, this operation does not depend on what principle of operation of the TPS is contactless or not. So, first we do the preparatory work. We disconnect the corrugated tube through which air passes, and thoroughly rinse it with alcohol, gasoline or another potent solvent. But one liquid is not always enough to achieve the best effect; you should also wipe the tube with a soft cloth. We carry out the same operation with the damper itself and with the intake manifold. In addition, do not forget to make a visual check, especially for the damper.

So, no mechanical damage was found? Then proceed directly to the adjustment of the throttle position sensor. First, take the key and loosen the screws. Then we raise the damper and sharply lower it all the way, keep in mind that you should hear a blow, otherwise repeat the operation again. We loosen the screws until the part stops “biting”. And only then it is possible to fix the position of the fasteners with nuts. Next, we unwind the bolted connections of the TPS and turn the body of the device. Next, set the throttle position sensor so that the voltage changes only when the throttle is opened. The setup is over, it remains to return everything to its place, tighten the bolts and enjoy driving your favorite car.

Replacing and choosing a sensor - non-contact or film?

If the element is out of order, then most likely the situation will be saved by its complete replacement. One of important points this stage - right choice new device. Of course, if you do not want to carry out all operations again after a short period of time, then you should give preference only to high-quality goods, and even more so avoid cheap Chinese fakes. In addition, do not stop your choice on film-resistive models. They are short-lived, and such savings can cost you a pretty penny. But non-contact throttle position sensors are highly reliable. They only cost a few dollars.

The film model has resistive tracks, while the contactless copy works on the principle of the magnetic effect. His constituent parts the stator, rotor and magnet protrude. At first the magnetic field has a huge impact. The material of the second is chosen such that the magnet has no effect on it. The distance between the elements of the TPS does not change and is selected at the assembly stage. Needless to say, the proximity sensor is not repairable.

The film model has resistive tracks, while the contactless copy works on the principle of the magnetic effect. His constituent parts the stator, rotor and magnet protrude. At first the magnetic field has a huge impact. The material of the second is chosen such that the magnet has no effect on it. The distance between the elements of the TPS does not change and is selected at the assembly stage. Needless to say, the proximity sensor is not repairable.

The replacement itself will take you much less time than choosing a device. But despite the fact that the process is quite simple, we will consider it in detail. We prepare a Phillips screwdriver, an o-ring for the throttle pipe and, of course, the part itself. Replacement begins with turning off the ignition if the car was started. Open the hood and do not forget to disconnect the battery. To do this, remove the negative terminal.

Now we find the sensor on the throttle pipe and remove the block with wires from it, most likely you will have to wring out a special plastic latch. Then we unscrew the fixing bolts and dismantle the device. There is a foam ring between the TPS and the nozzle, and its replacement is also necessary. And only after that you can install the sensor itself. Fix the device firmly with bolts, otherwise the vibration will not benefit it and cause failure. We connect back the block with all the wires. Sometimes battery they forget to turn it off, in this case it is necessary to de-energize it for at least five minutes after installing a new device and connecting the block to it.

You can check if the element is working correctly as follows. We open the damper and pull the gas cables to turn the TPS drive sector. If the position of the sector does not change, then the sensor should be reinstalled. At the same time, we rotate it 90 degrees with respect to the damper axis. And finally, check the voltage with a tester, if its values are the same as those indicated above, then the device is working.

You can check if the element is working correctly as follows. We open the damper and pull the gas cables to turn the TPS drive sector. If the position of the sector does not change, then the sensor should be reinstalled. At the same time, we rotate it 90 degrees with respect to the damper axis. And finally, check the voltage with a tester, if its values are the same as those indicated above, then the device is working.

Phantom Repair Opportunities

It should be said right away that the repair of throttle position sensors is extremely rare. Firstly, the part itself, even the most expensive one, costs only a few dollars, and it makes sense to spend money. Secondly, it is simply impossible to make repairs in most cases, for example, to restore a worn base layer. However, in some models, you can slightly shift the resistive tracks relative to the slider and thereby extend the life of the device.

So, there is a special screw on the sensors. With its help, the position of the tracks is fixed. If they are already worn out, then this very screw should be loosened, so the location of the slider will change a little, and you can be a little patient with replacing the device. But just don't count on a long-term delay. Naturally, we remember that the contactless TPS cannot be repaired. This is done with the adjustment, repair and replacement of the throttle position sensor, now you can operate the car for several more years and not even think about such issues.

Subscribe to our feeds

header

Almost any vehicle has a large number of various mechanisms and components. Therefore, when a malfunction affects even a small unit, all this promises serious problems for the entire machine. The throttle position sensor is one of these small and at the same time very significant components in the car. Consider its purpose, principle of operation and the main causes of malfunctions, as well as how to deal with them.

Purpose and principle of operation

In automobile internal combustion engines running on gasoline, an integral part of the intake system is a throttle valve. The main task of this mechanism is to regulate the amount of air entering the chambers. Thus, it ensures proportional mixing of air with fuel for maximum combustion results. As in many others, in Kia Spectra cars, this device is mounted in the area between the air filter and the intake manifold. We can say that its action is akin to an air valve: when open, a pressure equal to atmospheric pressure is reached, and when closed, it decreases to a vacuum.

The sensor components include variable, fixed and single-turn resistors, the total resistance of which is approximately 8 kΩ. The throttle position sensor has two extreme outputs, one of which receives the voltage supplied by the controller.

The second output is powered to ground. The signal is sent to the controller through a resistor, which transmits the actual position of the damper at the current moment. Depending on the position, a signal is transmitted, the pulse of which varies between 0.7 - 4 V.

Types of TPS

As a rule, two types of remote sensing are distinguished: electrical and mechanical. The latter is usually used in inexpensive cars. It consists of the following components: idle speed controller, housing, sensor, throttle. As for the case, it is part of the cooling system. To ensure crankcase ventilation and filtration of gasoline vapors, a system is provided that is connected to the sensor by pipes. When the throttle is in the closed position, when starting or warming up the engine, the idle speed controller provides the desired speed of the crankshaft. IAC provides air to the intake system past the closed damper.

The electric type throttle sensor is more popular and is used in the latest generation of cars. This type is the most productive and has an electronic control system, which achieves the most ideal torque value, increases power, and reduces fuel consumption. Unlike mechanical, there is no direct interaction between the gas pedal and the damper, and the idle speed is controlled by changing its position. In addition, the electronics itself is able to calculate the optimal torque value. This process is carried out thanks to the operation of the control unit and input sensors. It is thanks to the sensors and the control unit that many processes are ultimately connected with the regulation of the air supply.

This module consists of a throttle valve, a spring mechanism, an electric motor, a gearbox, a TPS and a housing. There is a practice of installing two throttle position sensors at the same time. This is due solely to precaution, since it allows, in the event of a malfunction of one, to switch work to another. In this case, a non-contact throttle position sensor and a sliding contact are distinguished. The spring mechanism ensures the return position of the damper in emergency mode.

Fault symptoms

Like any mechanism, TPS is prone to malfunctions. Checking its condition will determine the breakdown. In case of serious damage, it will need to be replaced.

For starters, you should pay attention to the number of revolutions made by the engine at idle. If their value jumps, then you should check the correct operation of the sensor. It may need to be replaced. Another point of failure - with a sharp release of gas, the engine stalls. Or, during acceleration, the speed jumps, there is no response to pressing the gas pedal, the engine speed is in the range of one and a half to three thousand. All this indicates the need to check the operability of the TPS, and, if necessary, either the entire assembly or its components should be replaced.

Diagnostics

Diagnostics for any car, as well as for Kia, is carried out in the same way. All you need from the tools is a multimeter. Next, you need to start the car and see if the Check Engine is lit. If everything is in order, turn off the engine, find the mass under the hood and start the engine again. Let's start looking for the downside. We are looking for a power wire. You should check if current is flowing to the sensor. Then you need to make sure that the idle opening is functioning properly. To do this, we connect one of the wires of our measuring device to the sensor connector, and change the position of the damper with the second. If everything is OK, then the value of the device will change. If the value has not changed, this indicates a malfunction of the variable resistor and may need to be replaced.

Such a sensor is considered a kind of potentiometer. He is responsible for determining the angle of rotation of the throttle and. The operation of the engine depends on the accuracy of its indicators: the data affect the calculation of the fuel supplied to the engine cylinders. Speaking more plain language, then he monitors the position of the damper - is it open or closed.

In addition, the correctness of the ignition and the operation of the automatic transmission depend on it. It is necessary to evaluate the importance of this device and monitor its condition - defects can adversely affect the car. A failed TPS can cause the engine to stall, which will critically affect the road position at the time of driving.

In other words, a faulty sensor sends a signal to the system that the throttle is open, which, in turn, leads to an increase in fuel supply. The engine "chokes" and breaks down. In addition, the operation of the machine in the "emergency" mode provokes a quick breakdown of the TPS.

Symptoms of a TPS malfunction

The throttle position sensor plays a big role in the process of fuel combustion, because it is fed into the calculation of the readings of the device. If the sensor is faulty, a "Check" notification should appear on the dashboard. Such an icon only states the fact of a malfunction, but does not recognize a specific problem. Signs of damage can be:

- Complications in starting the engine;

- Increase in gasoline consumption;

- Increase in idle speed;

- "Dips" in speed during acceleration;

- The engine stops in "neutral";

- Motor power drops during movement;

- Check engine.

It is worth noting that "Check Engine" may appear with each ignition for a split second, immediately disappearing. A sign of a breakdown is the constant glow of the indicator. It is recommended to contact the motorist.

TPS check

If the vehicle shows one or more of the symptoms of a problem, the sensor needs to be checked. This process does not require special skills: it is enough to have a multimeter and follow a certain sequence of actions.

First of all, you need to turn off the ignition. Pay attention to whether the "Check Engine" light is on. If it goes out, then you can open the hood and inspect the TPS. To do this, you need a multimeter with which readings will be taken.

- Check for negative. In order not to disconnect each wire, it is enough to simply pierce them. In the same way, you should find the "mass".

- Find out if the sensor is receiving power. Depending on the car, the voltage can be different - 5 or 12 volts. Turning on the ignition, you need to pierce the wires in turn: the meter should show 0.7 volts.

- Manually open the throttle, which will cause the voltage to rise above 4 volts.

- Next, you need to turn off the ignition, disconnect one connector. Connect a multimeter between one of the other connectors and the output of the slider.

- Slowly turn the sector by hand, following the indications of the arrow. A smooth rise without hesitation indicates that everything is normal. A step increase in measurements indicates that critical problems have formed on the resistor track. These readings are important because they affect the operation of the control unit that supplies fuel to the injectors. The ECM takes over the data, starting from them, so if the throttle position does not correspond to reality, problems with the fuel supply will begin.

If the TPS is faulty, it. In addition, you need to do a few checks to prevent future breakdowns. It is advisable to completely replace the sensor - a small cost will allow the engine to work fully. Problems for which it is recommended to replace the sensor:

- Deformation of the sensor, which leads to distortion of the transmitted information;

- The idle contacts do not open properly.

After replacement of TPS The new one does not require additional configuration. By default, it considers an empty stroke to be the zero mark.

Throttle Position Sensor Repair

mending faulty sensor throttle position is very rare. The best solution is to replace the device with a new one - even the most expensive copy will cost no more than a few dollars. The second reason is the frequent impossibility of repair: it is impossible to restore the erased base layer and similar problems. Nevertheless, in some devices it is possible to move the resistive tracks relative to the slider and extend the life of the TPS.

Each sensor has a screw that fixes the position of the tracks relative to the slider. At high degree wear, you can loosen the screw, thereby moving the slider. Throttle position sensor adjustment is temporary and will allow you to postpone the purchase of a new one. This measure may last for several years.

Replacement of TPS

- Removing the sensor from the car is necessary to install a new one. First of all, you need to turn off the power supply by disconnecting the battery terminals. The wires that are connected to the device must also be disconnected. After unscrewing the fixing bolts, the TPS can be removed. When installing a new, original spare part, no adjustment is required.

- directly. To begin with, the spare part is connected to the electronic control unit, after which the terminal is put on the battery. With this algorithm of actions, all factory settings will be saved. Attention: it is important to install only original devices. The sensor from another model of the machine does not fit. The necessary device can be bought in special stores or from an official representative of the brand of the car. Buying online or on the market most often leads to the acquisition of counterfeit goods. The choice of the seller should be taken carefully and seriously. Motors