The engine does not develop power what to do. Reasons why an injection engine does not develop full power. List

At the present time, a fairly common problem in many cars is that the engine does not work at full power. If in this case the problem is not corrected as soon as possible, this is fraught with consequences. Firstly, in this mode, engine wear is significantly increased, which can lead to failure of its main components. Secondly, there is a significant deterioration in the driving characteristics of the car. Thirdly, an increase in fuel consumption is possible.

In contact with

Causes of engine failure

Of course, the first thing to do is to diagnose and determine the cause of the problem. In this case, there may be several:

- repeated strong overheating of the engine;

- incorrect operation of the ignition system;

- insufficient filling of the cylinders or the supply of a poor working mixture;

- a significant drop in the level of compression in the cylinders;

- engine malfunctions.

First you should check ignition system because the ignition may be too early or too late.

In this case, the exhaust manifold is very hot, at low speeds the engine will not work well, and when starting with the handle, it will sometimes give back blows. With all this, frequent knocks of a metallic nature in the engine will be constantly heard. If so, just adjust the ignition system. Otherwise, the problem should be sought in the vacuum and centrifugal regulators or in the automatic preignition control devices.

The main reasons for the failure of the centrifugal regulator, which corrects the ignition timing depending on the number of revolutions, are the weakening of the springs and the sticking of the weights. You can determine this using synchronograph.

To eliminate the malfunction, it is necessary to replace the weakened springs with new ones or eliminate the jamming of the weights.

Vacuum regulator may not work properly due to jamming of the ball bearing of the breaker panel, air leakage into the spring plane, or loss of spring elasticity. It is diagnosed in the same way as centrifugal - using a synchronograph. With such a malfunction, it is necessary to correct the operation of the advance angle regulators and correctly set the ignition. In addition, the cause of a decrease in engine power may be a sticking of the throttle on the axle, that is, its incomplete opening. At the same time, the axle should be cleaned and the damper drive should be checked to eliminate the cause of jamming.

Vacuum regulator may not work properly due to jamming of the ball bearing of the breaker panel, air leakage into the spring plane, or loss of spring elasticity. It is diagnosed in the same way as centrifugal - using a synchronograph. With such a malfunction, it is necessary to correct the operation of the advance angle regulators and correctly set the ignition. In addition, the cause of a decrease in engine power may be a sticking of the throttle on the axle, that is, its incomplete opening. At the same time, the axle should be cleaned and the damper drive should be checked to eliminate the cause of jamming.

The next step is to inspect air filter, and if necessary, wash disassembled, and then change the oil. Plus, it is imperative to check the health of the springs and valves of the gas distribution device, adjust the clearance and replace worn elements.

The reasons for incomplete filling of the engine cylinders with the working mixture can be a large amount of coke and tar deposits in the pipeline, the use of unsuitable fuel, sticking of the float chamber valve and various kinds of malfunctions in the muffler.

They are eliminated, respectively, by cleaning the inlet pipeline, replacing fuel, correcting jams and repairing the muffler. Loss of engine power also occurs when a lean mixture enters the cylinders, which can occur for several reasons.

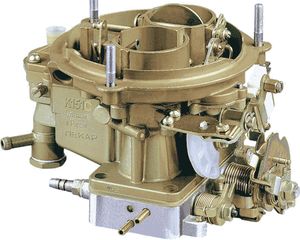

If the fuel channels of the power system are contaminated and the jets in the carburetor are clogged, it is necessary to thoroughly clean the contaminated channels and rinse the jets well. This also causes a decrease in engine power.

If the fuel channels of the power system are contaminated and the jets in the carburetor are clogged, it is necessary to thoroughly clean the contaminated channels and rinse the jets well. This also causes a decrease in engine power.

If there is a clogging of the sump screen, seizing of the fuel pump elements or a breakthrough in the diaphragm, the jam should be eliminated first, then the filter and sump screen should be cleaned, and the damaged diaphragm should be replaced with a new one. If there is a suction of air flows at the junctions of the carburetor elements, it is necessary to tighten the bolts and replace the worn seals. Well, a violation of compression in the cylinders is eliminated by setting and adjusting its level.

Thus, with the timely elimination of the problem of reducing engine power, you can avoid rather unpleasant consequences, the elimination of which will take you quite a lot of time and money. Remember that in order to avoid this kind of breakdowns, it is imperative to carry out a periodic complete diagnostics all systems in your vehicle.

The loss of engine power should be paid attention when it rolls over the 15 percent mark and if the car (in good condition) accelerates with difficulty on a flat, dry and hard road. There are plenty of reasons for this phenomenon, since in a car, as in a living organism, everything is interconnected.

The most common causes of power loss power unit

In contact with

- One of the elementary reasons for a decrease in engine power can be early ignition. In this case, the force of the exhaust gases goes against the movement of the piston due to the fact that the fuel mixture ignites prematurely. As a result, the engine cannot develop its full power.

- Late ignition also negatively affects the speed of the car. Here, the fuel mixture, on the contrary, does not have time to burn out until the moment when the piston comes to a dead center and the energy received, it turns out, is far from being fully used.

- The third reason may lie in malfunctions of the vacuum regulator of an advancing of ignition. Engine speed is directly related to how well the carburetor throttles are open. If the regulator diaphragm is damaged, it begins to function with great difficulty or fails altogether, which, in fact, immediately affects the power of the power unit.

- Also, it may be guilty of reducing engine power. centrifugal ignition timing controller, the failure of which leads to the described problem. With an increase in engine speed, the centrifugal regulator begins to increase the ignition timing, but if its weights stick, then the angle does not change throughout the entire operation of the engine and it loses its power.

In this case, excessive fuel consumption is often observed due to early ignition, which occurs due to the rapid stretching of the weight springs.

- The normal operation of the engine, and, accordingly, of the combustion chambers, cannot be imagined without valve tight fit in their designated saddles. Depending on the type of engine, the gap between the shim pusher and the end of the rod must be of a certain size. If the gap is increased, then the tightness of the combustion chamber is violated, which significantly reduces the power of the engine. And with a reduced clearance, the valve edges and seats usually burn.

You can determine a loose fit by the shots: if the shot goes into the carburetor, then this means that the intake valve does not fit snugly, and if the shot goes into the muffler, it means that the exhaust valve “sins” with a tight fit.

- Last on the list, but not least, is the reason worn piston rings. In this situation, compression in the cylinders decreases, which immediately responds to engine power. Determining the wear of the rings can be quite simple. To do this, you need to remove the crankcase ventilation hose from the breather and if smoke comes out of there, it means that the rings are worn out. Smoke resembles a dark jet with a pulse.

You still do not know how much to charge the battery? Find out from here.

Insufficient filling of the cylinders with the working mixture

But what could be the reason for the decrease in engine power when the ignition is adjusted and the ignition timing regulators are in good condition? In this case, you should pay attention to the fullness of the working mixture of the cylinders. Most often, this problem occurs due to throttle sticking, so sometimes you need to pay attention to its drive. After that, you need to check the health of the air filter, which, if necessary, is quickly removed, and a new one is installed in its place.

But what could be the reason for the decrease in engine power when the ignition is adjusted and the ignition timing regulators are in good condition? In this case, you should pay attention to the fullness of the working mixture of the cylinders. Most often, this problem occurs due to throttle sticking, so sometimes you need to pay attention to its drive. After that, you need to check the health of the air filter, which, if necessary, is quickly removed, and a new one is installed in its place.

As practice has shown, the lack of a working mixture in the cylinders can occur for four reasons:

- excessive soot in the engine cylinders;

- large deposits of coke and tar in the inlet pipeline;

- sticking in the float chamber of the needle valve;

- use of fuel with an octane rating that does not match the number prescribed by the instructors.

Lean working mixture

The entry of a lean working mixture into the cylinders is also one of the reasons for the reduction in engine power.

There are a number of reasons for the formation of a lean mixture that can be eliminated fairly quickly:

Sometimes when driving a car, the driver notices strange things - the car picks up speed more slowly, consumes more gasoline, the engine is heard better. This is most likely due to power loss. There can be many reasons why the engine does not develop proper power.

How to understand that the engine power has dropped

A whole list of parameters affects the smooth operation of the engine.

This is usually felt immediately by the following symptoms:

- The car accelerates more slowly;

- Fuel consumption increases;

- You have to “turn” the motor more in order to somehow accelerate. Engine performance is worse.

Checking indicators on the stand + video

To accurately verify the drop in power, the car must be sent to the power stand. Typically, such devices can be found in car services, tuning shops or dealerships. You can see how this happens in the video.

Reasons for declining engine performance

Change the gas station for a while and watch the agility of the car. Possibly a bad fuel problem.

Change the gas station for a while and watch the agility of the car. Possibly a bad fuel problem. The appearance of a problem on gasoline (carburetor or injector)

In the case of a gasoline carburetor engine, the reasons may be as follows:

- early ignition. The fuel mixture ignites prematurely, the force of the exhaust gases resonates with the direction of piston movement, resulting in reduced power.

- Late ignition. The mixture does not have time to burn for full cycle engine operation, which means that it does not develop the necessary power.

- Problems with the vacuum ignition timing controller. Found only on carbureted engines!

- Problems with the centrifugal ignition timing controller. They also lead to early ignition.

- Loose fit of valves in their saddles.

- Worn piston rings.

- Throttle stuck.

- A large amount of carbon deposits in the cylinders.

- Intake manifold clogging.

- Using fuel with the wrong octane rating.

- Lean working mixture caused by air leakage, fuel line contamination, air duct clogging;

- Clogged filters.

- Clogging of jets or carburetor fittings, incomplete opening of its dampers.

- Water entering the carburetor.

- Incorrect adjustment of the composition of the fuel mixture.

In the case of an injection engine:

- Clogged fuel and air filters.

- Problems with the electric fuel pump.

- Incorrect operation of the electronic control unit (ECU) of the engine.

- Problems with fuel injectors.

- Incorrect operation of sensors.

- Faulty lambda probe.

- Injector failure.

- Carbon deposits in the cylinders.

- Worn seals, gaskets, rings.

Why the diesel engine does not develop the desired performance

- Poor quality fuel.

- Fuel filter clogged.

- Clogged air filter.

- Failure of the turbocharger (extremely important these days - atmospheric diesel engines are almost never found. Check the quality of the turbines).

- Malfunction of fuel injectors.

- Clogged particulate filter.

- Clogged fuel pickup in the gas tank.

Detailed video about the causes of power loss

Poor throttle response due to clogged catalytic converter

As you know, power can be lost due to the contamination of the catalyst located in the muffler. How to check it?

- Measure the pressure in the exhaust system. If the value obtained is greater than 0.5 atmospheres, the catalyst needs to be replaced or removed.

- Warm up the engine well, measure the temperature exhaust pipe before and after the catalyst. If the temperature before and after is the same, the catalyst is clogged. Similarly, if the temperature after is lower.

- Ringing inside the catalytic converter.

In case of problems with the catalyst, do not remove it without subsequent replacement. Extraneous noise and the overall noise of the engine will increase, the resonance of the exhaust system will be disturbed, and this practically does not affect the engine power. It is better to install a new catalytic converter than to drive without it.

Ways to increase engine power

- Refuel with higher octane rating than recommended.

- Replace the standard air filter with a zero resistance filter.

- Replace standard exhaust system to straight line.

- Engine chip tuning.

- Replacement engine oil for higher quality and less viscous.

Loss of engine power is an annoying problem for any motorist. The car does not drive as it should, and sometimes it is very annoying, and sometimes it is not safe at all, so finding the root causes and eliminating them is an important and necessary task. Good luck on the roads!

› The engine does not develop full power…Lean mixture entering the cylinders. Filling the cylinders with a lean mixture always leads to a significant reduction in engine power. In this case, the car moves at lower speeds, it takes more time to accelerate on a dry road with a hard and smooth surface if the car's chassis mechanisms are in good technical condition.

The reasons for the formation of a lean mixture are as follows:

clogging of jets and channels in the carburetor, contamination of fuel lines, freezing of water in the power system. In this case, it is necessary to blow out the jets, channels and contaminated fuel lines using a tire inflation pump, and if necessary, clean them with copper wire by disassembling the carburetor;

stuck fuel pump valves, clogged strainer or ruptured diaphragm. In this case, the jamming of the fuel pump valves is first eliminated, the strainer is washed, and the broken diaphragm is replaced or temporarily restored in the manner described earlier;

air leakage at the junction of the carburetor parts, the carburetor flange with the exhaust pipe, the intake pipe flanges with the cylinder block due to loosening of the fasteners, as well as damage to the gaskets. The suction point can be detected with soap suds. A window is formed in the soap suds in the supposed place of suction. Air leakage is eliminated by tightening nuts or bolts, as well as replacing the corresponding seals;

wear of the fuel pump drive lever, clogging of the air hole that communicates the fuel tank with the atmosphere, jamming of the air damper. Eliminate these malfunctions as follows: replace the defective parts of the fuel pump, clean the air hole of the plug, check and, if necessary, adjust the length of the carburetor air damper control cable.

Late ignition. If the engine does not develop full power, it is best to check the ignition installation. If the ignition is too late, the engine loses throttle response. A significant reduction in power occurs for the reason that the mixture does not have time to burn out at the moment when the piston is at TDC. The combustion of the mixture continues as the piston moves down. This is evidenced by increased heating of the exhaust pipeline. It will be too hot, as some of the mixture burns out when released.

You can verify the violation of the ignition installation as follows. Driving in direct gear flat road at a speed of 50-55 km / h, sharply press the throttle control pedal. If the ignition is installed correctly, slight and short-term knocks should appear, disappearing with further acceleration of the car. The absence of knocks means that the ignition is late. Most often this happens when the grade of gasoline used is changed (for example, A-93 was temporarily used instead of A-76 gasoline). In this case, the ignition timing can be tried to be adjusted using an octane corrector (see Fig. 9). To do this, it is necessary to loosen the fastening of the housing 2 of the breaker-distributor on the engine and turn it by hand against the direction of rotation of the cam by one or two divisions of the scale 1 of the octane corrector towards the advance (+), and with strong short-term knocks in the direction of rotation of the cam towards the delay ( -). By adjusting the ignition setting, it is necessary to achieve stable engine operation.

early ignition. A decrease in engine power also occurs when the ignition is too early, when the combustible mixture ignites prematurely and the gas force acts against the piston, which moves to TDC. At the same time, frequent and ringing metallic knocks are heard in the engine, detonation may occur, the engine does not work well at a low crankshaft speed, and sometimes gives back blows when starting with the handle.

If by adjusting the ignition timing using the methods discussed earlier, it is not possible to achieve the desired results, then, obviously, there are malfunctions in the devices for automatically adjusting the ignition timing - centrifugal or vacuum regulators.

Defective centrifugal ignition timing controller. The centrifugal ignition timing controller starts working at 400-600 min-1 and regulates the ignition timing only depending on the crankshaft speed.

If malfunctions occur in the centrifugal regulator - weakening of springs 5 (Fig. 38) or sticking of weights 3 - this will lead to a violation of the ignition timing. When the regulator weights are stuck, the ignition timing at both low and high crankshaft speeds will remain the same. Meanwhile, for high crankshaft speeds, the ignition timing should be earlier.

Late ignition at high crankshaft speeds causes a decrease in power and increases gasoline consumption. If the springs 5 of the regulator are weakened and the weights 3 diverge completely, then even at low crankshaft speeds there will be a large ignition advance, which will also lead to excessive fuel consumption and a decrease in power. The operation of the centrifugal ignition timing controller can be checked in the following simple way.

Without removing the ignition breaker-distributor from the engine, remove the lever 2 of the breaker and turn the cam 1 by hand in the direction of rotation of the roller 4 until it stops. Weights 3 will then open. Then lower the cam, and under the action of the springs 5 weights it will return to its original position. If jamming is detected, it is necessary to eliminate it, and replace the weakened springs.

Faulty vacuum ignition timing controller. On the way, the car has to move both on a flat road and on a road with slopes. Suppose that when driving at a constant speed both on a flat road and on a hilly road, the centrifugal regulator will give only the same ignition advance. But when driving on a hilly road, the engine load and throttle opening are much greater, so the ignition advance must be less than when driving on a flat road at the same speed. The adjustment of the ignition timing when the throttle opening (engine load) changes is performed by a vacuum regulator (Fig. 39).

Rice. 39. Scheme of operation of the vacuum ignition timing controller:

1 - carburetor pipe; 2 - vacuum regulator tube; 3 - housing of the vacuum regulator;

4 - spring; 5 - diaphragm; 6 - thrust; 7 - panel finger; 8 - breaker panel

It may have the following malfunctions: loss of elasticity of the spring 4, air leakage into the spring cavity, wear or damage to the diaphragm 5 located in the middle part of the housing 3 of the vacuum regulator, seizure of the ball bearing 6 (see Fig. 38) and the panel 7 of the breaker-distributor. When the spring 4 (see Fig. 39) of the vacuum regulator is weakened at low and medium loads, the ignition advance increases. If, however, air is sucked into the cavity where the spring is located (if diaphragm 5 is damaged), then the ignition timing will decrease at low loads. If too much air is sucked in, the vacuum regulator will not work at all.

On the way, the serviceability of the vacuum regulator can be checked by shaking the breaker panel on the bearing.

In this case, it should be checked and determined whether the gap between the finger 7 of the panel and the rod 6 of the diaphragm 5 of the vacuum regulator has been increased and whether the rod itself is jumping off.

If, however, a vacuum is created in the tube 2 of the vacuum regulator disconnected from the nozzle 1 of the carburetor, then, if it is in good condition, the breaker panel should turn in the opposite direction to the rotation of the cam.

A more accurate check of the serviceability of the vacuum ignition timing regulator and the elimination of identified malfunctions are carried out by specialists at a car service station.

Violation of clearances in the valve mechanism. It is known that a tight fit of the valve in the seat, i.e., its complete closure, is ensured due to the thermal gap in the valve mechanism. In case of violation of the normal values of thermal gaps established by the requirements of the factory instructions for the operation of vehicles, the engine loses power. At small gaps, the valves and their seats burn out. The presence of large gaps in the valve mechanism causes not only a loss of engine power, but also a characteristic metallic knock of the valves. In addition, loose closing, for example, of the exhaust valve due to abnormal clearances is characterized by “shots” in the muffler, and a loose fit of the intake valve is characterized by “sneezing” in the carburetor.

Both small and large gaps in the valve mechanism have a negative impact not only on the efficiency of the engine, but also on the service life of its parts. Abnormal clearances in the valve mechanism are adjusted in the manner discussed earlier.

Wear of piston rings. Piston rings provide tightness between the piston and cylinder, preventing gases from escaping into the crankcase, and also prevent oil from entering the combustion chamber.

With wear of the piston rings (burning of the rings in the piston grooves, loss of their elasticity), the compression in the cylinders sharply decreases, which leads to a loss of engine power, increased consumption of oil, gasoline; black smoke comes out of muffler.

The compression in the engine cylinders is checked using a compression gauge and manually. Manual verification requires skill; you need to do it like this:

unscrew all the spark plugs, except for the spark plug of the first cylinder, and turn the engine crankshaft with the crank until the compression stroke ends in the first cylinder;

then alternately screw the spark plug into subsequent cylinders and again turn the engine shaft with the starting handle. Comparing the effort expended to overcome the resistance to cranking during the compression stroke in each cylinder, it can be assumed which cylinder has low compression.

To check the compression with a compression gauge, it is necessary: warm up the engine to a temperature of 80-85 ° C, unscrew the spark plugs, install the compression gauge tip tightly into the spark plug hole of the first cylinder and fully open the throttle and air dampers;

crank the engine crankshaft with the starter for 2-3 s and note the readings of the compression gauge.

In a serviceable engine, the difference in compression gauge readings between the engine cylinders should not exceed 1 kgf / cm2, and the pressure at the end of the compression stroke should correspond to the following data (kgf / cm2):

ZAZ-968 "Zaporozhets" ... 8

ZAZ-1102 "Tavria". . . … 9.5

VAZ-2101, -2103, -2105, -2106, -2107… 9.7

VAZ-2108, -2109… 9.9

"Moskvich-2141" ... 8.5

"Moskvich-2140" ... 9.8

GAZ-24 "Volga" ... 9.4

Worn or defective piston rings can be identified by the following inspection. After determining the pressure in the cylinders, fill in 23-30 cm of engine oil through the spark plug holes and turn the crankshaft with a starter. In this case, an increase in compression will indicate a malfunction (wear) of the rings or a cylinder, the absence of an increase - a leak in the valves. Coked piston rings are replaced with new ones.

You can try to eliminate a slight burning of the piston rings yourself without disassembling the engine. To do this, prepare a mixture consisting of 50% solvent No. 647 or acetone, 25% kerosene and 25% AC-8 oil and pour 100 cm3 into each cylinder through the spark plug holes. Then crank the crankshaft several revolutions, after an hour add another 50 cm to each cylinder and leave for 7-8 hours. After that, pour 30 cm3 of a mixture of gasoline and oil into the cylinders and drive 20-25 km by car. Then drain the oil from the engine crankcase and flush the lubrication system with liquid oil.

Silencer pollution. During the operation of the car, due to the operation of the engine on an overly enriched mixture, its incomplete combustion occurs. Unburned fuel is thrown out in the form of soot, and part of it settles on the inner wall of the muffler, gradually polluting it. In addition, muffler contamination is also possible at the time of careless reversing of the car on a bumpy dirt road. If the muffler is dirty, the engine loses power. The condition of the muffler can be determined by visual inspection and a slight blow from the outside. A clean muffler produces a high-pitched, metallic sound, while a dirty muffler produces a muffled sound.

A dirty muffler must be cleaned, as this leads not only to a loss of engine power, but also to excessive consumption of gasoline, as well as premature wear of the muffler.

The ability of the power unit to dynamically accelerate the car and maintain the highest possible speed is directly dependent on the power. It is quite obvious that a noticeable loss of power indicates certain malfunctions of the motor and its systems.

A cause for concern can be considered that the car stops accelerating normally on a flat stretch of road for no apparent reason. Next, we will look at the reasons why the engine does not develop full power or does not pull the engine, and we will also talk about diagnostic methods and available ways to fix this problem.

The motor does not develop power: why is this happening

To answer the question of how the engine power is removed, it is enough to recall the passport data of a particular car and a dyno. Such a stand is a "measuring" device that allows you to determine the actual power of the motor according to the indicator on the wheels. According to the passport, the manufacturer usually indicates the power of the internal combustion engine at. Given this information, it is not difficult to understand that the technical specifications, for example, 200 hp on the shaft when tested on a dyno will turn into 175 hp. In other words, the measurements at the stand will differ from the passport data.

Now let's look further. The gradual loss of engine power is a natural process as the power unit wears out. I would like to note that normally this happens gradually and almost imperceptibly to the driver. In other words, an engine with a mileage of 150-250 thousand km. may not give out "passport" power, show even less on the stand, while the average loss is 5-15%, depending on the degree of wear and a number of other factors.

If there is a drop in power by 20% or more, then the engine needs diagnostics. Note that if the motor does not reach full power, the following symptoms may be present:

- when you press the gas pedal, there is a pause;

- the car jerks when accelerating;

- the engine smokes (in transient and loaded modes);

- increased working temperature ICE;

- there is an excessive consumption of fuel and oil;

The presence of the above additional signs helps to more accurately find out why the engine does not develop power and install possible cause. In the list of main malfunctions and failures, experts single out ignition, wear of the main components, filling quality and composition of the fuel mixture.

Engine Lost Power: Common Causes

- Ignition problems. Too early will mean that pre-ignition of the mixture of fuel and air occurs. As a result, the expanding gases oppose the rising piston instead of pushing it down. Under such conditions, engine power will drop noticeably. The same is true for late ignition. Late ignition of the fuel-air mixture leads to the fact that the expanded gases “catch up” with the piston going down, useful energy is wasted. It turns out that both in the first and in the second case, the driver intensively presses the gas pedal, the fuel is consumed, but there is no full return from the engine.

Also mention should be made of problems associated with the vacuum and centrifugal ignition timing controller. The fact is that malfunctions of these solutions affect the ignition timing and its change in relation to different operating conditions of the internal combustion engine. For example, with an increase in speed, the regulator shifts the ignition angle.

In other words, the degree of opening of the throttle valve and the increasing frequency of rotation of the crankshaft at the same UOZ do not allow the motor to develop full power. A loss of power may be noted after a flashing or in order to save fuel.

- Cylinder-piston group and. As mentioned above, wear, failures in the timing settings or the accumulation of soot in the combustion chamber leads to a loss of engine power. As for the gas distribution mechanism, incorrect, coke and soot can disrupt the normal operation of the valve mechanism. More precisely, the tightness of the combustion chamber is violated due to a loose fit (fit) of the valves to the seats. The fit can be broken if the valves are strongly "clamped". Engine coking also prevents the valve from closing normally. The fact is that the layer of soot prevents a normal fit. As a result, part of the gases breaks through loosely closed valves, overheating occurs, valve seats, etc. Coke deposits can additionally smolder under the influence of high temperature, causing the effect of uncontrolled ignition of the mixture, that is. All this leads to malfunctions and a decrease in the power of the power unit. As for the CPG, wear is a common cause of low cylinder compression. As a result, there is a breakthrough of gases into the engine crankcase, that is, the energy of fuel combustion is again consumed with large losses. Determining the cause is not particularly difficult. It is enough to remove the crankcase ventilation hose and assess the degree of smoke intensity. The presence of heavy smoke, going "pulsing", will indicate problems with the rings.

- Filling the fuel-air mixture and the composition of the mixture. Problems with the filling and composition of the fuel charge can reduce engine power even if the engine is in good condition, the ignition is set correctly. The most common cause is contaminated throttle valve or a malfunction of the throttle opening mechanism itself. .

What is the result

With that said, if the engine is not producing power, the cause could be ignition, air or fuel delivery. We add that a decrease in engine power can also occur depending on external conditions: temperature environment and atmospheric air pressure.

If the car “pulls” worse under certain conditions, then this is not a malfunction. For example, high in the mountains, engine power, especially atmospheric, decreases. Also in summer, in extreme heat, the fuel pump or carburetor can overheat.

As a result, I would like to recall that the condition of the fuel and air filters greatly depends on throughput intake and fuel system. For this reason, the filter elements must be changed in a timely manner, which ensures maximum efficiency from the engine.