How the exhaust system works. car exhaust system

Exhaust system (engine exhaust system) - a system for removing exhaust gases, as well as to reduce exhaust toxicity and noise levels during operation. The evolution of internal combustion engines in parallel with the tightening of environmental regulations and standards has led to the fact that the engine exhaust system today is much more structurally complicated compared to its early counterparts.

The device and principle of operation of the exhaust system

The basic exhaust system for internal combustion engines that comply with the Euro-2 standard and above consists of the following elements:

- receiving pipe;

- oxygen sensor (lambda probe);

- catalytic converter;

- resonator;

- muffler;

A diesel particulate filter is also installed in the exhaust system of the diesel engine at the catalyst installation site. For diesel engines, such a filter is an indispensable structural element. The automotive exhaust system is directly connected to, since the exhaust gases from the cylinders are discharged through the exhaust valves.

Exhaust from the cylinders enters the exhaust manifold of the engine. Behind the exhaust manifold petrol cars a catalyst (catalytic converter) is installed. As for a diesel engine, a particulate filter can be either a separate element or combined with a catalyst. Such solutions serve to effectively clean exhaust gases from harmful impurities.

Also in the design of the exhaust system there is always a silencer. All components are connected using special connecting pipes, almost the entire exhaust system (except for the exhaust manifold) is installed under the car and attached to its bottom.

The exhaust manifold of the exhaust system allows the exhaust to be removed and the cylinders to be purged from the residual products of combustion of the fuel-air mixture. The exhaust manifold material is often heat-resistant cast iron or other heat-resistant material.

The exhaust manifold of the exhaust system allows the exhaust to be removed and the cylinders to be purged from the residual products of combustion of the fuel-air mixture. The exhaust manifold material is often heat-resistant cast iron or other heat-resistant material.

The exhaust manifold constantly interacts with hot exhaust gases and is subject to significant heating, as well as significant temperature changes during the cooling of the manifold after the ICE stops working.

exhaust manifolds for different types motors can vary greatly in their shape and size. The structure of the exhaust manifold depends on the so-called oscillatory process at the inlet. In other words, the oscillatory process of the exhaust gases is consistent with the similar process of the fuel-air mixture in .

The downpipe (variants of a curved shape, depending on individual design features) is attached to the exhaust manifold through the "sole". The specified sole is attached to the receiving pipe by welding.

Also, the fastening of the downpipe can be implemented to the turbine outlet in the event that a particular gasoline or diesel engine is equipped. High performance cars may have more than one downpipe. With the help of the indicated exhaust pipe, the next element of the engine exhaust system is connected to the outlet - a pre-muffler (resonator).

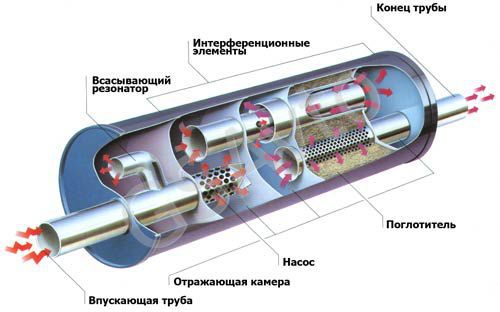

The muffler is a steel container, inside which partitions are made. This element provides noise reduction, and also reduces the speed of the flow of exhaust gases. Structurally, the muffler is usually divided into two parts.

The first part is the resonator. In the resonator, the exhaust flow is divided into parts, and there is also a decrease in the flow velocity. The resonator is made of heat-resistant material, similar to the intake manifold. Next, the exhaust enters the main part of the muffler.

The noise level inside the muffler is reduced as a result of the fact that sound waves are superimposed on each other a large number of times, and also the direction and volume of the exhaust gas flows previously decomposed into parts in the resonator are changed.

The catalyst is an element of the exhaust system, which neutralizes harmful components in the exhaust (hydrocarbons, nitrogen oxide and carbon). The design and location of the catalyst may differ depending on the specific vehicle model. Often the catalyst is installed just behind the exhaust manifold.

The device has a metal case, which is covered with a refractory material from the inside. The catalyst itself is located inside the housing and is actually a mesh coated with active components (platinum, palladium, etc.). After passing the exhaust through such a grid in the catalyst, chemical reaction, as a result of which toxic elements break down into relatively harmless for environment connections. In the exhaust system of diesel engines, a particulate filter is additionally installed, which traps soot particles.

Control of composition of exhaust gases EBU

In the event of such malfunctions, the electronic engine control system often transfers the motor to emergency mode. In the event that the muffler burned out on the car, such problems may not affect the stability of the internal combustion engine. At the same time, there is a noticeable decrease in acoustic comfort.

Exhaust system car (exhaust system) is, as is already clear from the name, the exhaust system. The exhaust system, contrary to popular belief, is a very important vehicle system. Its functions include:

- Reducing the toxicity of exhaust gases(positive effect on the environment)

- Noise suppression(reduces noise level)

- Discharge of hot, toxic gases behind the rear of the vehicle(prevents toxic gases from entering the cabin)

In addition, the exhaust system creates the necessary resistance to the exhaust gases, which affects the performance of the car. Also, exhaust systems, especially sports exhaust systems, play an important role in the appearance of the car, as well as in the sound, creating a pleasant timbre.

In addition, the exhaust system creates the necessary resistance to the exhaust gases, which affects the performance of the car. Also, exhaust systems, especially sports exhaust systems, play an important role in the appearance of the car, as well as in the sound, creating a pleasant timbre.

In the common people, the exhaust system is almost always simply called the "silencer". But this is not entirely true, since the muffler is just one of the components of the exhaust system. The exhaust gas removal system consists of: ![]()

- collector(connects several exhaust outlets into one);

- downpipe(connects the collector to the catalyst or corrugation);

- corrugations(reduces vibrations transmitted from the engine)

- catalyst(converts toxic gases to harmless ones);

- resonator(reduces noise level);

- middle pipe(connects the resonator to the muffler);

- muffler(performs the same function as the resonator, but is arranged a little differently and uses a special fiber as a sound-absorbing material).

Consider the operation of the exhaust system in more detail. After the combustion of the fuel mixture, a lot of unburned toxic gases remain, under high pressure they enter the manifold, the task of which is to connect all the exhaust outlets into one. The collector usually creates a high resistance for the exhaust gases, therefore, very often, in tuning and sports, the regular collector is replaced by the so-called "spider". In fact, this is the same collector, but it has smoother bends to reduce the resistance to gas flow. After the collector, the gases enter the intake pipe, in which the temperature can reach 1000 ° C. From the intake pipe, the gases enter through the corrugation into the catalyst, the main task of which is to burn out unburned harmful compounds and convert toxic gases into harmless ones. In most vehicles, it also reduces noise levels and gives the exhaust a pleasant sound. After the catalyst, already relatively harmless gases enter the resonator, which significantly reduces the noise level, further along the middle pipe (which often has a strange, bizarre, tricky, twisted shape, since it must repeat the geometry of the bottom of the body and leave room for other vehicle units) gases fall into the muffler, which also reduces the noise level, like the resonator, but has a slightly different device.

Causes of failure of exhaust systems

Any car enthusiast can say that the exhaust system of a car is faulty and needs to be repaired, since a faulty exhaust system is accompanied by:

Any car enthusiast can say that the exhaust system of a car is faulty and needs to be repaired, since a faulty exhaust system is accompanied by:

- loud "roar";

- engine power reduction(traction and acceleration deteriorate) ;

- unstable engine operation(rpm fluctuations at idle)

- the ingress of exhaust gases into the interior of the car;

- the appearance of soot on the details

Therefore, the repair of the exhaust system cannot be postponed, especially since repairing a "running" exhaust system will cost much a large amount . The most common cause of exhaust system failure is corrosion and mechanical damage. Rust "eats" the bodies of mufflers, catalysts and resonators, as well as intermediate pipes and welds for fastening parts. As a rule, this happens due to constant, strong temperature changes, water, salt and reagents entering the exhaust system, accumulated condensate inside the muffler and resonator, as well as due to the active chemical compounds contained in the system.

The design of the car uses many systems - cooling, oil, injection system, and so on. But few people pay attention to the exhaust. But it is no less important component of any car. Over the years, the design of this system has been improved. We will talk about what a car consists of and how it works in our today's article.

Purpose

As you know, in the engine during operation, the mixture ignites. This ignition is accompanied by a characteristic sound. During the explosion, a colossal pushing energy is generated. It is so large that it is able to raise the piston to top dead center. In the last cycle of operation, gases are released. They are released into the atmosphere under pressure. But what is an exhaust system for? It serves to dampen sound vibrations. Indeed, without it, the work of even the most technologically advanced motor would be loud and unbearable.

Thus, the exhaust system performs the following functions:

- Conclusion from the engine cylinders of combustion products.

- Reducing the level of toxicity of gases.

- Eliminate the ingress of combustion products into the vehicle interior.

Device

This system combines several components. In addition, it is directly related to the work of the timing. So, the classic VAZ exhaust system consists of:

- receiving pipe.

- Catalyst.

- resonator.

- Silencer.

- Various fasteners and sealing elements.

- oxygen sensor.

If we consider diesel cars, then the design will also have a particulate filter. What are all these elements? The device of each of them will be considered below.

Downpipe

This element is the first in the list and comes immediately after the exhaust manifold. Gases that have not yet cooled down enter the intake pipe. Therefore, the temperature can reach 600 degrees Celsius or more. In the common people, the downpipe is called "pants" for its characteristic shape. This element is made of especially strong and fire-resistant metal. Usually it is rough (it rusts over the years), but on more expensive cars it is made of stainless steel. If it is an engine with a large combustion chamber volume, several of these tubes can be used in the system design. This is done in order to reduce the resistance of gases. Otherwise, the motor will "suffocate" with its own gases.

Resonator

It is made in the form of a cylindrical jar. It is in the resonator that the first separation of the exhaust gas flow occurs. Also, due to the increase in diameter, the speed of the exhaust movement decreases.  Gases gradually dissipate in this chamber. Due to this, vibrations and partially sound are damped. Just like the "pants", the resonator is made of fire-resistant metal.

Gases gradually dissipate in this chamber. Due to this, vibrations and partially sound are damped. Just like the "pants", the resonator is made of fire-resistant metal.

Catalyst

This is perhaps the most complex and expensive component in any exhaust system. The body of this element is also made of fire-resistant metal. However, unlike the resonator and receiver pipe, it is multilayered. Inside this "jar" there is a ceramic rod. Additionally, the catalyst is equipped with a wire mesh. It covers the second element of the ceramic material.  In addition, the device has a layer of thermal insulation with double walls. Why is a catalyst so expensive? In addition to ceramics, expensive materials are used here - palladium or platinum. It is these components that convert harmful gases into hydrogen and safe vapors. In view of this, the minimum cost of a new converter is 40 thousand rubles.

In addition, the device has a layer of thermal insulation with double walls. Why is a catalyst so expensive? In addition to ceramics, expensive materials are used here - palladium or platinum. It is these components that convert harmful gases into hydrogen and safe vapors. In view of this, the minimum cost of a new converter is 40 thousand rubles.

particulate filter

If we consider the device of the exhaust system of a diesel engine, this element is worth noting. It is an addition to the catalytic converter. The filter is based on a matrix made of silicon carbide. It has a cellular structure and has channels of small cross section. The latter are alternately closed on one side and the other. The side part of the element plays the role of a filter and has a porous structure.

Until recently, matrix cells had a square shape. Manufacturers now use octagonal cells. This is how the soot is better captured and deposited on the filter walls.  How does this element work? The particulate filter operates in several stages. The first step is to filter the soot. Gases enter the element, and harmful substances settle on the walls. The second stage is regeneration. She may be:

How does this element work? The particulate filter operates in several stages. The first step is to filter the soot. Gases enter the element, and harmful substances settle on the walls. The second stage is regeneration. She may be:

- Passive.

- Active.

In the first case, harmful gases are purified by passing through the ceramic element. In the second, a special liquid is added - AdBlue. Usually such a system is used on trucks. It reduces emissions by up to 90 percent. The car has a separate tank for this liquid, and the system, after receiving the appropriate signal, injects part of the AdBlue into the catalyst. So, almost clean exhaust comes out of the pipe, containing hydrogen that is harmless to the atmosphere.

Lambda probe

It is also called an oxygen sensor. It is installed near the catalyst in a threaded connection. It is a sensitive element that comes into contact with exhaust gases.  The task of the sensor is to determine the temperature of gases and the presence of oxygen in them. Based on the read data, the ECU sends a signal to the intake manifold. If necessary, an additional portion of fuel is injected into the cylinders. What is it for? The fact is that the catalyst fully works only under the condition of elevated temperatures (at least 600 degrees). If the gases are colder, no filtration or conversion will take place. Therefore, the system adds more fuel to keep the catalytic rod temperature within the operating range. This system has practically no effect on fuel consumption (provided that it is in good condition).

The task of the sensor is to determine the temperature of gases and the presence of oxygen in them. Based on the read data, the ECU sends a signal to the intake manifold. If necessary, an additional portion of fuel is injected into the cylinders. What is it for? The fact is that the catalyst fully works only under the condition of elevated temperatures (at least 600 degrees). If the gases are colder, no filtration or conversion will take place. Therefore, the system adds more fuel to keep the catalytic rod temperature within the operating range. This system has practically no effect on fuel consumption (provided that it is in good condition).

Muffler

This is the very last element in the system. Silencers are of two types:

- Standard.

- Sports.

The first are installed on all civilian vehicles. The design of such a silencer involves the presence of several metal partitions. Also in the case there is a through which gases are directed from one partition to another. According to this scheme, the greatest reduction in the level of noise and vibration is made. The factory muffler is made of refractory metal. However, practice shows that its service life is an order of magnitude less than that of sports ones. The reason for this is the lack of a nickel-plated surface and too thin metal of the insides.

As for sports mufflers, they have a simpler design. It is a straight perforated tube with an expansion in the middle and filled with glass wool. this type is very large. As a rule, on co-currents, the diameter of the exhaust hole is one and a half to two times higher than that of standard ones. Thanks to this, a quick removal of gases and a good "exhaust" are made.  But why are such mufflers not installed on cars from the factory (with the exception of sports versions)? It's all about the level of their noise. As practice shows, such mufflers practically do not struggle with the damping of sound vibrations. Their task is to divert as much gas flow as possible to the maximum short period time. On the move, these mufflers make a hum, and when they pick up speed, they begin to “yell” even louder. Therefore, direct currents are not suitable for everyday comfortable driving. Although their design is more reliable and practical than that of the "civilian" counterparts.

But why are such mufflers not installed on cars from the factory (with the exception of sports versions)? It's all about the level of their noise. As practice shows, such mufflers practically do not struggle with the damping of sound vibrations. Their task is to divert as much gas flow as possible to the maximum short period time. On the move, these mufflers make a hum, and when they pick up speed, they begin to “yell” even louder. Therefore, direct currents are not suitable for everyday comfortable driving. Although their design is more reliable and practical than that of the "civilian" counterparts.

Sealing elements

So, we have listed the main components of the exhaust system and their design. However, we have not talked about how they connect to each other. Fasteners are made on bolts and clamps. The downpipe is connected to the exhaust manifold and resonator on two gaskets. Depending on the type of vehicle, the gasket can be made of pressed corrugated foil or solid metal. Additionally, a washer can be used. As for the muffler itself, it is connected to the resonator thanks to a clamp, with an overlap. On some machines, a ring can be used (for example, on the domestic "eight"). For better sealing, experts recommend using a heat-resistant sealant (up to 1100 degrees). It perfectly seals all gaps and prevents gases under pressure from escaping ahead of time.

Exhaust system malfunctions

The main symptom is the characteristic sound of gas removal. The car starts to “yell”, an unpleasant smell of gasoline or diesel appears in the cabin. Also, the car stops running normally. And if the exhaust manifold gasket is burned out, the “Check” will light up on the instrument panel. It indicates that the oxygen sensor is not working properly. Along with this, fuel consumption also increases (since the system cannot accurately dose fuel, as before). The way out is to replace the exhaust manifold gasket. Also inspect the condition of the pipes themselves. If they begin to rot or there are cracks at the joints, an exhaust system repair is required. The rot is cut out by a grinder and welded on new leaf metal. But as practice shows, more practical and fast way is to replace an obsolete element with a new one. Remember that the muffler is a consumable item. After 2-3 years, it must be replaced. The same applies to other elements, but their resource is slightly longer. For example, "pants" burn out after five years of operation.

About corrugation

The exhaust system (including direct-flow) may also include a corrugation. It is an additional damping element. Thanks to it, the load on other parts of the exhaust system is reduced. The sound of gas escaping becomes quieter. But it is worth noting that the corrugation in the exhaust system is the lowest element. In view of this, the owners often damage it.  The corrugation is not subject to repair. It is changed or a piece of a new pipe is welded in its place. As practice shows, the noise level practically does not increase after such repairs. The main thing is to achieve maximum tightness in the sealing elements. After all, a burnt gasket can be a serious cause of deterioration in the driving characteristics of a car.

The corrugation is not subject to repair. It is changed or a piece of a new pipe is welded in its place. As practice shows, the noise level practically does not increase after such repairs. The main thing is to achieve maximum tightness in the sealing elements. After all, a burnt gasket can be a serious cause of deterioration in the driving characteristics of a car.

Conclusion

So, we examined the structure of the exhaust system and its main malfunctions. Finally, let's give a little advice. When removing either the catalytic converter, take care to remove the oxygen sensor. If this is not done, the motor will “overflow” - fuel consumption will increase and an error will light up on the instrument panel. After removing the catalyst (it is changed to a flame arrester), a new firmware is uploaded to the ECU. A plug is installed in place of the sensor.

car exhaust system- this is a structural group of spare parts, the work of which starts from the manifold, passes through the catalytic converter and ends with the muffler. The main task of this system is to remove exhaust gases from the engine, as well as sound waves that are generated as a result of the combustion process.

More about exhaust system functions

As we said above, the exhaust system starts with a structural manifold. It is attached directly to the engine outlet. Particularly high temperatures and gas pressure prevail in this place. The sealing gasket located in this place is subject to the greatest load. Therefore, in most cases, it is made from a non-combustible graphite composition, and is partially framed with copper rings, which allows it to fit snugly against the engine outlet. As a rule, exhaust gases from each cylinder are collected in this manifold. For this, a Y-hose is used. There is also a lambda probe, which is responsible for the distribution of the catalyst. A catalytic converter is connected to the Y-hose, or directly to the manifold. In order to mitigate vibrations from engine operation, the connection is made by means of a flexible metal hose or spring-loaded bolted connection. The catalytic converter is the most important component of the exhaust system. Directly in it, with the help of a porous ceramic block coated with precious metals, exhaust gases are cleaned. In case of diesel engines, a particulate filter is used instead of a catalytic converter.

How does a silencer work, and why put two silencers instead of one?

The end of the exhaust system is a muffler. It is divided into several chambers, which are isolated from each other. The separate chamber technique divides the exhaust gases into several partial streams, thereby reducing the sound waves of each of the streams. This principle of operation is called the interference effect. As a result, back pressure is formed in the muffler, which has a direct effect on the operation of the engine. Therefore, it is not recommended to open or remove insulating materials.

The muffler itself is filled with soundproof basalt wool or metal shavings. Previously, asbestos wool was also used as a filler, but today this material is no longer used.

Today, large exhaust systems use an additional muffler. This is done allegedly because for powerful cars one muffler is not enough to absorb its “growl”. This is not entirely true. The use of an additional silencer is not necessary, since catalytic converters in modern cars also absorb sound, but a tribute to fashion forces car companies to install a second muffler, with which the car looks more “driven”.

The individual components of the exhaust system are interconnected by pipes. A large number of connection points has led to the fact that now the exhaust system is produced in one block. The negative point of this approach is the fact that if one of the components fails, it is necessary to change the entire system, but thanks to modern high-quality wear-resistant materials, exhaust systems are extremely durable, and you should try hard to break something there.

A car is made up of many parts. Performance, dynamics, power, safety depend on the stable operation of each of them. The failure of one part can lead to serious consequences up to an accident.

Of course, every driver knows that the heart of the car is the engine. But his work would not be possible without a quality exhaust system. To understand its importance, let's draw a parallel with biology. You know that thanks to the lungs, the respiratory processes in the body are supported. They are also responsible for removing carbon dioxide from the blood. If this does not happen, then oxygen starvation begins.

Of course, a lack of oxygen in the blood cannot lead to anything good. In the worst case, brain function is disrupted, which, in turn, can lead to death. In the event of a malfunction of the exhaust system of a car, everything is not so tragic. But loss of power and increased fuel consumption are guaranteed. That is why it is important to understand how this unit works in order to carry out repairs if necessary.

Attention! In the worst case scenario, a malfunction of the car's exhaust system can lead to the ingress of exhaust gases into the passenger compartment.

An important function of the exhaust system of a car is to reduce engine noise. Also, one cannot ignore such important functions as improving the performance of internal combustion engines and cleaning exhaust gases before being released into the atmosphere.

History of creation

The first models of internal combustion engines created a deafening roar. In addition, they were very low-powered and allowed cars to reach extremely low speeds compared to modern supercars.

To slightly increase the power, the automakers of that time created the exhaust systems of a car in such a way that the exhaust gases entered the atmosphere immediately through a special valve. This device was a primitive analogue of a silencer, the installation of which had a positive effect on power and efficiency.

The driver himself had to open the valve of the exhaust system so that the exhaust gases would come out. At the same time, a deafening whistle was heard, frightening everyone around. This action was also accompanied black puffs of smoke.

Attention! The operation of the exhaust system valve was so terrible that drivers were forbidden to open it within cities.

Due too hands-free work exhaust system, there was a kind of confrontation between the townspeople and drivers. As a result, the governments of all countries have issued a law prohibiting the opening of the valve within the city.

Naturally, resourceful automakers could not miss such a chance to get ahead of their competitors. The development of a quieter exhaust system for cars began to gain momentum.

The first muffler prototype was created by automotive pioneers The Reeves Pulley Co. The author of the same invention is Milton Reeves. It happened in 1896. scientist created partition system, which was designed to minimize the noise generated by the internal combustion engine.

Of course, for more than 100 years, the muffler for the exhaust system of a car has gone through many upgrades. One of the main ones was carried out by the French engineer Eugene Goodry. It happened not so long ago. In 1962, the scientist filed a patent for a catalytic silencer. This structure is the basis for modern device responsible for noise reduction.

The basic structure remained unchanged. All the same partitions greatly reduced the sound of the engine. But now they were used to create Additional materials, increasing the efficiency of the entire exhaust system. Moreover, all these elements were placed in closed systems.

Attention! Modern mufflers have a similar design, with one exception. Now most manufacturers use fiberglass as an absorbent material.

If we talk about overall structure exhaust system of a car, then over the past 50 years it has not changed much. Small improvements were made in the early 2000s, but they also concerned the muffler. Variable flow designs emerged. This made it possible to moderate the noise of the internal combustion engine for a different number of revolutions.

Also interesting innovations include electronic silencers. They serve to make the noise lower, using special headphones for this purpose. This modification allowed the design to take another small technological step into the future.

How does a car exhaust system work?

Device

To understand how the exhaust system of a car works, you need to take a closer look at its structure. The design itself is closely related to the functioning of the mechanism responsible for the distribution of gas. The mechanism itself consists of exhaust valves and a manifold.

The composition of the exhaust system of a car includes the following structural elements:

- intake pipe,

- resonator,

- catalyst,

- muffler,

- sensors or lambda probe.

Also, do not forget about the particulate filter, which makes the exhaust system for cars safer for the environment. This is the canonical scheme of the exhaust system of a car. Naturally, manufacturers can contribute to the design additional elements and modifications to achieve greater performance.

Attention! In detail, the main device of the exhaust system of a car, you can see in the diagram below.

The car exhaust pipe is a curved design with a welded sole. It connects to the exhaust manifold. In some modifications, a connection with a turbocharger can be observed.

The material of the exhaust pipe of the car exhaust system is fire-resistant metal. Although sometimes manufacturers can use stainless steel, such cases are quite rare. Cars with increased power have several pipes.

The resonator is shaped like a jar. It is in it that the exhaust gases are separated. Also, this element significantly reduces the speed of the exhaust. The material of manufacture is refractory steel.

The catalyst cleans the exhaust gases. By appearance the device resembles a metal container. The inner layer is fireproof. The main structural element is the body. It, in turn, is divided into ceramic and metal.

The ceramic catalyst consists of three components that help neutralize the exhaust:

- The first element is a simple wire mesh. It is usually made from stainless steel.

- The mesh covers the ceramic cushion, which is also the second element. Its constituent elements are aluminum silicate and mica.

- Thermal insulation completes the design of the catalyst. In fact, this is a simple case, which is characterized by high heat resistance and has double walls.

The metal catalyst of the car exhaust system is coated with a layer of palladium or platinum. The basis is corrugated foil. In all other elements, the design is similar to the ceramic counterpart.

The lambda probe is mounted on a threaded connection. His the main task is to fix the amount of oxygen in the exhaust gases and transmit information to the control unit. On its basis, certain adjustments to the operation of the internal combustion engine are carried out.

The muffler is a simple metal container. Partitions and special materials are placed inside to help reduce noise during the operation of the car engine. The main task of the device is to moderate the flow of exhaust gases.

All elements of the design of the exhaust system of a car work with each other in close cooperation. The failure of one element leads to the fact that the entire system begins to fail. That is why car manufacturers spend a lot of time and money to create a truly reliable structure.

Principle of operation

The principle of operation of the exhaust system of a car is not particularly complicated. Moreover, it has not changed much since the introduction of this structural element into the car.

The exhaust system of the car still works thanks to the exhaust valve. When this mechanism opens, the exhaust gases enter the exhaust manifold. Then it all depends on the type of engine.

If the car has Gas engine, then the exhaust system sends gases through the exhaust pipe. In diesel engines, things are a little different. The exhaust gaseous substances cause the impeller to rotate. Naturally, this greatly increases the efficiency of the device.

Attention! In diesel internal combustion engines, exhaust gases enter the exhaust pipe only after the turbocharger impeller is forced to work.

From the exhaust pipe of the car, gaseous substances are redirected to the catalyst. There is a settling of harmful impurities. More precisely, active elements. The structural element itself is able to work normally only at temperatures of 250 degrees and above.

The lambda probe is responsible for the chemical composition of the gas. Ideally, the exhaust system of a car has two sensors at once. One is at the inlet to the catalyst, and the other is at the outlet. This allows you to ensure high productivity of the system.

The main advantage of systems with two sensors is a more accurate display of data. This structure allows you to more accurately fix the ratio of air and fuel.

After the lambda probe collects information, it sends it to the control unit. Based on the data received, commands are issued for the system responsible for injecting the fuel mixture into the engine cylinders. More precisely, there is an adjustment of the ratio of air and fuel.

As soon as the exhaust gases pass through the catalyst, the exhaust is “quenched”. As a result, the gaseous substance that enters the muffler poses a much lesser danger to the environment.

Attention! The mufflers change the direction of the exhaust. Because of this, the noise is drastically reduced.

After passing through all the elements of the car exhaust system, the exhaust gases escape into the atmosphere. In many ways, the efficiency of this unit depends on the thickness of the pipes, which also represent important part mechanism. Moreover, the catalyst and muffler must be clean enough. Otherwise, the exhaust may be difficult.

If the catalyst and muffler are clogged, then the exhaust gases will accumulate in the car's cylinders. It is because of this that in most cases the power of the motor drops. In the most difficult cases this leads to the fact that the entire fuel system becomes unusable.

Results

The exhaust system plays a huge role in the operation of the car. If it fails, there is a serious drop in power and increased fuel consumption. If timely measures are not taken, then this automotive unit may fail and cause damage to all other units.